What is a pump impeller?

A pump impeller is a rotating disc with vanes on its sides. It used in centrifugal pumps to enhance fluid flow. The impeller is mounted on the pump shaft. The shaft transmits power from the motor to the impeller. Both the impeller and shaft rotate at the same speed (RPMs). The impeller thus helps to transfer energy to the pumped fluid by moving the fluid radially outwards from its center. Centrifugal pump manufacturers design the pump such that when the pumped liquid leaves the impeller into the casing, the flow velocity reduces while pressure increases. This helps build up high pressure to ensure fluid reaches the required destination. There are three types of impellers: closed, open, and semi-open. The kind of impeller dictates the area of application. Pumping fluid using the wrong impeller may severely damage the pump and lead to low efficiency and high running costs.

What is an open impeller?

The open impeller is designed such that the vanes are open on both sides. As such, it does not have a protective shroud. By lacking protective covers, this impeller is weak and thus recommended for use in inexpensive and small pumps that do not experience significant strain. By not having support on either side, this impeller is suitable for use in fluids that have suspended solids as it cannot clog.

Figure: Open-impeller.

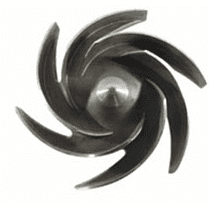

Semi-open impeller

This impeller has a back-wall support that enhances the strength of the vanes while the other side remains open. Its design lies between the open and closed impeller regarding NPSHr and efficiency. They are suitable for medium centrifugal pumps and fluids with small solids.

Figure: Semi-open impeller.

Closed impeller

The closed impeller is designed such that its front and back sides are enclosed. This design makes the impeller strong enough for high flow rates. It has high efficiency compared to the semi-open and open types. It also has low NPSH. However, these impellers are more expensive due to their complex design. They rely on close-clearance wear rings to maintain efficiency and lessen axial loads. They are used in large pumps for clean fluids. If the fluid transported has solid particles, they will clog the impeller and thus cause damage to the pump.

Difference between open, semi-open, and closed impellers

| Open impeller | Semi-open impeller | Closed impeller |

| · Their vanes are open on both sides

· Suitable for fluids with solids · Operate at high NPSH |

· One side has wall cover and, the other side is open

· Can handle small-sized solids · Handle fluids at medium NPSH |

· Vanes are covered on both sides

· Only for clean fluids · Low NPSH |

Factors to consider when selecting centrifugal pump impeller

Type of material

The material type is critical factor as it determines if the impeller will withstand corrosion and abrasive wear. One of the suitable materials for use is stainless steel due to its anti-heat, anti-contamination, and anti-corrosive properties. Another good choice would be bronze. Bronze is ideal when transporting salty liquids. In such applications, the suitable type of bronze would be gunmetal (a type of bronze).

Cast iron is another suitable material. This material is cheaper relative to bronze, brass, or stainless steel. It is also resistant to alkali corrosion. However, if the fluid is acidic, the impeller will wear out rapidly through rusting. A suitable material would be coated with polymers when selecting an impeller to transport acidic fluids. The coating ensures that the impeller remains protected and thus increases service life.

Compatibility

Centrifugal pump manufacturers make the impellers with large sizes to leave room for changes in viscosity. Such designs lead to power wastage as the pump operates at high pressure. Trimming the newly acquired impeller diameter is recommended to ensure it is compatible with the pump.

Type of fluid

There are different types of fluids. Understanding fluid properties is essential as it helps to select an economical impeller. Also, it is necessary to know if the fluid contains solid particles. If the pumped liquid has solids, use an impeller that allows solids to pass through without clogging. Such an impeller would be an open impeller for large solids and a semi-open impeller for small solids. Clogging of solids in the pump causes high power consumption, impeller damage, and even a low flow rate. When pumping clean fluids, the closed impeller is the best. Where the liquid is viscous, it is advisable to consult pump experts to guide you on the best centrifugal pump impeller. Viscosity is a crucial factor when selecting any centrifugal pump as it affects power consumption and flow rate.

Cost

When choosing the impeller, consider all the above mentioned factors and include maintenance costs. This will ensure that the chosen impeller will not drain your pocket due to frequent maintenance and repairs.