Stainless Steel Magnetic Drive Pump

What is stainless steel magnetic drive pump?

Stainless steel magnetic drive pump is made of stainless steel material that uses magnets to transmit power from the motor to the pump impeller. There are two magnets in this pump that is the drive (outer) and the driven (inner) magnet. The outer magnet is driven by the motor. As this motor is driven by the motor it forces the inner magnet to rotate the pump impeller thus causing fluid flow through the pump. Stainless steel magnetic drive pump manufacturers design this pump for use in transporting toxic and hazardous products which when leaked into the environment can cause huge damage or the user can be prosecuted. As such, the designers follow strict design standards and codes to ensure the pump is leakage-proof. This type of pump has the advantage of tolerating high temperatures relative to those pumps made of plastic or coated with plastic materials.

Figure: Stainless steel magnetic drive pump

Components of a stainless steel magnetic drive pump

Motor

The motor is the component that provides the power needed to run the pump. The motor converts electrical energy from the main supply to mechanical energy. The mechanical energy is responsible for the kinetic energy that runs the pump impeller to allow fluid flow.

Magnets

Two magnets are the outer and inner magnets. The two magnets are arranged with their poles opposite to create a magnetic field pattern. The rotation of the two magnets causes impeller rotation.

Impeller

This is the component tasked with causing fluid flow from the sump through the pump to the casing and the delivery pipe. Stainless steel magnetic drive pump manufacturers design the impeller with backward curved vanes which rotate to impart energy increasing fluid flow velocity.

Casing

This is the component of the stainless steel magnetic drive pump used to house internal parts. This part is designed such that it reduces the fluid velocity while increasing the pressure energy.

Suction pipe and valve

A suction pipe is a pipe with one end connected to the pump inlet port and the other end submerged into the source of the liquid. The suction valve is the valve that allows fluid flow from the source to the pump.

Discharge valve

This is the valve through which the fluid flows from the pump to the pipeline.

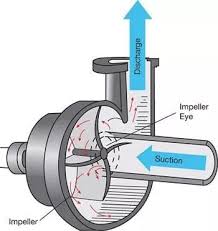

Figure: Components of a stainless steel magnetic drive pump

How does a stainless steel magnetic drive pump work?

A stainless steel magnetic drive pump operates by employing magnetic technology. This technology uses two magnets with their poles (north and south) opposite. This arrangement creates magnetic force responsible for causing the impeller rotation. To start the pump, the motor is turned on. As such, the motor shaft and thus the outer magnet start rotating. With the outer magnet rotating, the inner magnet starts rotating due to the magnetic field pattern. The rotation of the inner magnet forces the pump impeller to spin at the same speed as the motor shaft.

Impeller rotation creates a vacuum in the pump. Due to this vacuum, atmospheric pressure on the surface of the fluid being pumped forces the fluid into the pump. Once the fluid gets into the pump, it meets the impeller rotating at a very high speed. The impeller rotation imparts velocity on the fluid forcing it to move into the pump casing. The casing then reduces the fluid’s kinetic energy as it increases its pressure energy. The fluid then proceeds to the delivery pipe and to required destination.

Figure: Working of a stainless steel magnetic drive pump

Types of stainless steel magnetic drive pumps

Horizontal stainless steel magnetic drive pump

This is the type of stainless steel magnetic drive pump in which the motor and impeller are connected in a horizontal plane. This pump is easier to install and repair since the pump components can be accessed easily. Most of the pumps are of this configuration. Due to the short distance between the pump and the motor, the pump has low noise and vibration as well as smooth operation. However, this pump occupies a large floor space during installation.

Figure: Horizontal stainless steel magnetic drive pump.

Vertical stainless steel magnetic drive pump

This is the pump that is installed such that the motor and the pump are in a vertical orientation. This pump is used where the liquid level is below the horizontal pump limits. This pump tends to be more costly relative to the horizontal type. The pressure head of this pump depends on the length of the head and rotation speed. This pump has a smaller footprint relative to the horizontal type. It offers efficient low flow and high head. However, it becomes complicated during repair, especially where the pump is used and installed in deep pits. The noise levels are also higher relative to the horizontal type.

Figure: Vertical stainless steel magnetic drive pump.

Single-stage stainless steel magnetic drive pump

This is a pump designed to operate using one impeller. This pump is of small weight relative to one with more impellers. However, it produces less pressure energy compared to the multistage pumps. The pump is also smaller in size and thus its cost is lower compared to a pump with two or more impellers.

Figure: Single-stage stainless steel magnetic drive pump.

Multistage stainless steel magnetic drive pump

This is the pump designed with two or more impellers. Each impeller constitutes a stage. The impellers are joined in series when the pump is meant to produce high pressure. For the pump to produce high fluid flow capacity, the impellers are connected in parallel. Each impeller stage operates by directing the fluid to the next impeller until the fluid finally enters the casing. Stainless steel magnetic drive pump manufacturers design this pump to be installed vertically or horizontally.

Figure: Multistage stainless steel magnetic drive pump.

Applications of stainless steel magnetic drive pump

- Stainless steel magnetic drive pumps are used to transport chemicals.

- They are used to handle corrosive and hazardous liquids as they are resistant to corrosion and free from leakage.

- They are used to transport fats and cooling liquids.

- They are used in oil refineries and petrochemical transportation.

- Stainless steel magnetic drive pumps are used in water treatment.

- They are used in the transportation of cryogenic fluids.

- They are used in pressure boosting.

Advantages of stainless steel magnetic drive pump

- These pumps are free from corrosion hence they can handle corrosive liquids like acids.

- They are versatile as they are used in different industries to transport different fluids.

- Stainless steel magnetic drive pumps use magnetic technology which eliminates leakage.

- They are reliable and have low maintenance costs. These pumps do not use mechanical seals hence they have few parts to wear out. This reduces the cost and time for repair.

- No misalignment challenges. There is an air gap between the motor, magnet, and pump. Without physical contact, the problem of misalignment and thermal expansion which can cause premature failure is not a problem.

- It reduces the risks of fines. Stainless steel magnetic drive pump manufacturers follow a list of safety and environmental regulations when designing the pump for flammable and hazardous fluids to ensure there will be no leakage which can cause legal action.

- These pumps are available in a wide range of sizes.

- They are durable.

Disadvantages of stainless steel magnetic drive pump

- The use of these pumps is limited to high temperatures since the magnets can easily be damaged rendering the pump inoperable.

- Stainless steel magnetic drive pumps are best for handling clean liquids since solids stick to the magnets causing failure or reduced performance.

- These pumps are more expensive relative to other pumps.

Best practices for stainless steel magnetic drive pump

The following are some of the best practices for starting and operating a stainless steel magnetic drive pump to enhance reliable services with minimal repairs and costs.

Pre-check

Check the motor fan to ensure it can rotate freely. This can be done by inserting a screwdriver through the cover of the fan and rotating it manually.

Prime

This is the process of filling the stainless steel magnetic drive pump with fluid before you start pumping.

Open the discharge valve

After priming, open the exit valve fully and close it to prevent air from being trapped in the discharge and suction line.

Motor rotation check

Check the direction of the motor and or pump rotation is correct as recommended by the stainless steel magnetic drive pump manufacturer. This can be checked against the rotation arrow indicated in the pump manual or on the housing.

Start the pump

After performing the above checks and priming the pump completely, open the suction valve fully. Next, turn the pump on and open the discharge valve slowly. Check to ensure the pump is running without noise or vibrations and that the fluid is flowing at the recommended rate and pressure.

Suction valve operation

Ensure the suction valve remains open during the pumping process. The suction valve is not for regulating flow. When you need to regulate fluid flow, use the discharge valve.

Power monitor

Keep monitoring the pump power to ensure it does not run dry which can damage the pump. The use of such operational procedures helps to lower operational costs and also enhance long service life. However, in case the pump develops problems use the following troubleshooting checks to solve the problem.

Troubleshooting stainless steel magnetic drive pump

Low fluid discharge

- Closed discharge valve. Open the valve.

- Leakage through the suction line. Replace or repair the suction line.

- The pump is not primed. Prime the pump.

- The system head is higher than what the pump can handle. Try to reduce the system head.

- The fluid being pumped has high viscosity. Use the pump for the fluid recommended by the stainless steel magnetic drive pump manufacturer.

- The pump is working on a very high suction lift. Replace the pump with a higher-rated one or reduce the suction lift.

- The motor is rotating in the wrong direction. Change the direction of motor rotation.

- The impeller or suction line is clogged. Open the pump and remove any material interfering with pump performance.

The pump discharge pressure is low

- The fluid might have air or gas in it. Remove the air or gas.

- The impeller is of small diameter. Check the impeller diameter or use another pump with a larger impeller.

- Motor speed is low than expected. Increase motor speed.

The pump consumes a lot of power

- Fluid density or viscosity is very high. Use the pump for fluid viscosity/density recommended by the stainless steel magnetic pump manufacturer.

- There are faulty connections in the motor. Check the motor’s electrical connections and correct any faulty connections.

- Under voltage of the motor. Improve motor voltage.

The pump produces excess noise or vibration

- Loose connection on the pump casing. Tighten the bolts and nuts connecting the pump casing to attain the torque recommended by the stainless steel magnetic drive pump manufacturer.

Summary

The stainless steel magnetic pump operates by employing magnetic technology to run the pump. This pump is manufactured with two magnets the drive and the driven magnet. Rotation of the drive magnet due to the shaft rotation forces the driven magnet to rotate inside the pump. With the driven magnet rotates, it forces the pump shaft and the impeller to rotate at the same speed as the motor shaft. This rotation creates a pressure difference between the inside of the pump and the fluid sump. As such, fluid enters the pump, and then it is transported to the required location through pipelines.

Stainless steel magnetic drive pump manufacturers produce various types of pumps such as horizontal pumps, vertical pumps, multistage pumps, and single-stage pumps among others. Applications of this pump include oil refinery, petrochemicals, and other chemicals, water treatment, food products, pressure boosting and crystalizing and cryogenic fluids among others. The advantages of this pump are leakage proof, reduced fines, durability, ease of installation and repair, and no misalignment issues.