Self-Priming Centrifugal Water Pump

What is a self-priming centrifugal water pump?

A self-priming centrifugal water pump is designed to operate without the need for the operator to prime it before the pumping process starts. The priming process removes the air in the pump and in the suction line. The pump has a priming chamber that stores water. This water recirculates within the pump, removing air. Without removing the air, the pump will not transfer water, or it will move less amount of water than it should. Clearing the air in the pump makes it easy for the atmospheric pressure to push water from the tank into the pump, where the pumping process starts. As the name suggests, this pump uses centrifugal force to move water from the source to your desired destination. A component known as an impeller creates the centrifugal force. This type of pump is straightforward to install and repair.

Self-priming centrifugal water pump manufacturers produce pumps of various sizes ranging from small size to large size. Such size varieties ensure that a pump can always fit your application area.

Figure: Self-priming centrifugal water pump

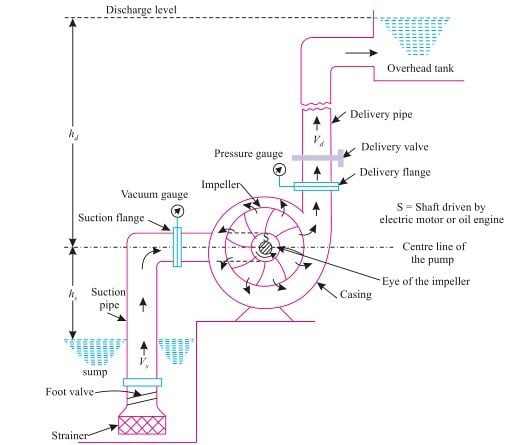

Components of a self-priming centrifugal water pump

Shaft

The shaft is a metallic component that transmits power from the prime mover (electric motor or IC engine) to the pump. Two shafts are the motor shaft and the pump shaft. A coupling connects the two shafts. The shaft rotates only when the motor turns on, and there is power from the mains supply.

Prime mover

The prime mover is the source of power for the pump. In most cases, the prime mover is an electric motor, but other pumps use an internal combustion engine. The IC engine or motor provides mechanical power to the pump. The motor output power depends on the expected total head and expected water flow rate. As such, for a high head and significant flow rate like 500 m3/h, a higher rated motor such as 473 hp is used.

Impeller

The impeller is a disc with curved vanes and mounted on the pump shaft. The impeller is usually rotated at high speed to impart kinetic energy to the water. It spins at the same speed as the shaft rotates at high speed. Two main types of the impeller are open and closed impellers.

The open impeller has its vanes attached to the hub and is mounted on the pump shaft. This impeller does not have a wall surrounding the vanes, making it weaker than the closed impeller. As such, this impeller is used for pumps that handle water with solids and also for smaller pumps. However, this impeller has the advantage of being more uncomplicated and fast to clean and repair. Closed impellers have front and back walls around the vanes. This design helps to improve impeller strength. As such, this impeller type is used in large pumps to handle clear water.

Figure: Open and closed impellers.

Casing

The casing is a shell-like component that covers internal parts of the pump, like the impeller, bearings, seals, and shaft. The casing helps seal off the pump’s water against the atmosphere. There is a distance between the casing’s internal surface and the impeller’s outermost surface. This distance depends on the pump type and the fluid to be pumped. Self-priming centrifugal water pump manufacturers design the casing such that the flow area increases as the water moves out. Such a design helps decrease flow velocity so pressure energy can improve before the water leaves the pump. The high-pressure energy is the one that transfers the water to the required location. The casing is also a structural member on which the pump is connected to the foundation.

Bearings

Bearings are mounted on the left and right end sides of the shaft. They support the shaft and hydraulic loads due to the water loads. They also enhance smooth rotation on the shaft with minimum friction, which serves energy.

Suction pipe and valve

A suction pipe connects the water storage device to the pump to allow water to move into the pump. Self-priming centrifugal water pump manufacturers design the suction pipe with a strainer to filter out solids contained in the water. The suction valve controls the amount of water that enters the pump from the storage tank. The suction valve also prevents the backflow of water into the pump.

Discharge pipe and valve

The discharge pipe connects the pump to the pipeline conveying the water to your required destination. The discharge valve helps you control the water leaving the pump into the pipeline.

Figure: Components of a self-priming centrifugal water pump.

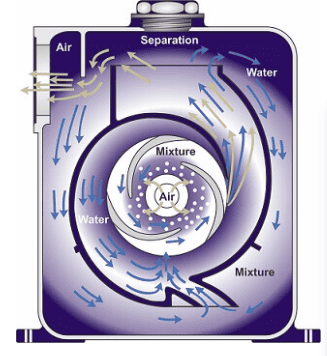

How does a self-priming centrifugal water pump work?

The pump starts operating when the impeller rotates, creating a vacuum in the impeller’s eye. This vacuum draws air from the suction line into the pump. Simultaneously, the vacuum creates a liquid ring inside the pump casing. As such, a gas-tight seal is created inside the pump, preventing air from going from the discharge end to the suction side. The water traps air bubbles on the impeller blades and takes them to the discharge port. The air bubbles are removed through the discharge, and the water returns to the reservoir under gravity.

Next, the water rises the suction pipe again as it evacuates the air. The process goes on until all the air is expelled and its space is occupied by water. After discharging all the air, the normal water-pumping process starts. The water pumping process occurs due to the impeller rotation, which creates a vacuum in the pump. The vacuum forces the water into the pump through the center of the impeller. The high-speed impeller imparts high-velocity energy onto the water. The water velocity starts reducing as the water moves along the flow area. The reduced rate leads to increased pressure that drives the water to the required location.

Figure: Working of a self-priming centrifugal water pump

Types of self-priming centrifugal water pumps

Single-stage self-priming centrifugal water pump

Single-stage type of pump is the most common type of self-priming centrifugal water pump. This pump uses one impeller. It is cost-effective and easy to install, clean, and repair. However, it is best for low and medium heads and flow rates.

Multistage self-priming centrifugal water pump

A multistage self-priming centrifugal water pump uses more than one impeller. The impellers in the pump are arranged from left to right in series. Each impeller forms a stage, so the stages equal the number of impellers. At each stage, the pressure energy increases; thus, the more the impellers, the more the output pressure. This type of pump is recommended to transport water for high heads and large flow rates. The pump is quite expensive relative to the single stage pump. The multistage pump is also heavy and hard to clean and repair due to the many impellers. However, it is inevitable for significant water flow rates and high heads.

Monoblock self-priming centrifugal water pump

A Monoblock self-priming centrifugal water pump is unique because it has one shaft that runs from the motor to the pump. This pump does not have a coupling to connect the motor and pump shaft common in other pumps. The motor and pump are connected as one block, hence the name “Monoblock” pump. Such design helps to reduce power losses common in pumps that use coupling.

Figure: Monoblock self-priming centrifugal water pump.

Magnetic drive self-priming centrifugal water pump

As the name suggests, the magnetic type of pump uses magnetic technology to connect the pump and motor. This pump has two magnetic sets: the outer magnet and the inner magnet. The external magnet is connected to the motor shaft so that as the motor rotates, it also rotates. Due to the magnetic field pattern, the rotation of the outer magnet forces the inner magnet to turn. The internal magnet is connected to the pump shaft. As such, the rotation of the inner magnet causes the pump shaft to rotate. This type of pump does not use seals common in other pumps. As such, it does not have water leakage in standard pumps when seals wear out. The pump is expensive, but its operating cost is highly pocket friendly because the magnets can serve you for around seven years without being replaced.

Figure: Magnetic drive self-priming centrifugal water pump.

Applications of self-priming centrifugal water pumps

- These pumps are used in firefighting applications.

- They are used in the commercial and domestic water supply.

- Self-priming centrifugal water pumps are used in drainage and irrigation.

- They are used in flood protection.

- These pumps are used to supply water in construction areas.

- Self-priming centrifugal water pumps are used for mining applications to drain water.

- They are used in wastewater treatment.

Advantages of self-priming centrifugal water pumps

- These pumps do not need to be primed.

- They are easy to install, clean, and repair.

- They are of various sizes suiting different fluid flow rates and heads.

- They can are cost effective and durable.

- They have high fluid flow rates.

- Self-priming centrifugal water pumps are of low noise and vibration.

Disadvantages of self-priming centrifugal water pumps

- Self-priming centrifugal water pumps have low efficiency relative to standard pumps. This is because they have larger clearance and large volute leading to low pressure.

- There are times when the pump needs to be primed manually. For example, when the pump is new and after the pump has stayed for a while without pumping water.

Troubleshooting self-priming centrifugal pumps

No water flows through the pump

- No power in the motor. Check the motor power cables are well connected to transmit power.

- Motor rotation reversed. Change the motor direction to match the rotation arrow on the pump casing.

- The suction valve is closed. Open the suction valve.

- The discharge valve is closed. Open the discharge valve.

- Low pump speed. Check the motor frequency and voltage are as recommended by the self-priming centrifugal pump manufacturer and if not, contact an electrician or power company to make corrections.

- High suction lift. Reduce the suction lift or lower the pump towards the water source.

Water flow rate decreases

- Leakage on the suction line. Repair the suction line.

- Blockage in the pump. Disassemble the pump according to the self-priming centrifugal water pump manufacturer’s instructions and clean any foreign material in the pump.

- The discharge valve is partially open. Open the discharge valve fully.

- Clogged filter. Clean the filter.

- Clogged suction valve or suction line. Clean the suction valve and suction pipe as necessary.

Bearings overheating

- Lack of lubrication. Lubricate the bearings adequately.

- Shaft/coupling misalignment. Align the shaft/coupling perfectly.

- The bearing covers are too tight. Loosen them.

Too high vibration or noise

- Clogged impeller. Open the pump and remove blocking materials.

- Bearings are worn out. Replace bearings.

- Defective or worn-out impeller. Replace impeller.

- The pump operates outside its duty range. Ensure the pump only works in the range recommended by the self-priming centrifugal water pump manufacturer.

Summary

Self-priming centrifugal water pump operates without being primed. Priming is filling water in the pump to expel air in the suction line. Without removing the air, the pump won’t transfer water. The priming process starts when the pump is started, and the impeller rotates, creating a vacuum in the pump. This vacuum draws air and water mixture into the pump. Due to low density, air rises to the discharge port, where it is expelled while the water goes back to the reservoir. The process repeats until all the air is removed, and the pump starts the normal pumping process. However, the self-priming centrifugal pump needs priming when operating for the first time after being purchased. It also needs to be primed if it has stayed without pumping water for long period.

Self-priming centrifugal water pump manufacturers produce several pump types, such as single-stage, multistage, Monoblock, and magnetic drive pumps, among others. Applications of this pump include firefighting, agriculture, domestic and commercial water supply, and construction, among others. Advantages of this pump include self-priming, easy installation, versatility, easy cleaning and repair, simple and compact design, and high flow rate.