Triple Screw Pump

What is a Triple screw pump?

A triple-screw pump, also called a three-screw pump, is a rotary positive displacement pump comprising three screws. The screws are intertwined, and they turn in precisely machined bores. The shape of the screws resembles a screw thread, and the liquid moves along the screw axis from suction to discharge when the screws turn. Pump manufacturers design the three-screw pump such that one screw serves as the driver while the other two as driven screws. The electric motor spins the driver screw, which rotates the other two screws surrounding it. During operation, the screws mesh together within the pump casing, creating a sealed chamber that moves uniformly between the three spinning screws in the axial direction. The pumping fluid flows in the sealed chamber axially and continuously from the inlet to the discharge. Triple/ three screw pumps classify under positive displacing pumps because they enclose a fixed volume of liquid and move it mechanically through the system.

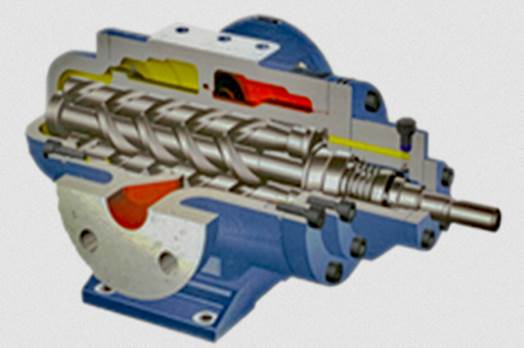

Figure: Showing the configuration of triple screw pump

Tripple screw pump manufacturers design this pump to provide a wide range of flow rates (from 2 to 2600 liters per minute), to handle fluid with a temperature of up to 150-degree centigrade, a differential pressure of up to 100 bars, and a wide range of viscosity (between 3 and 5000 square millimeters per second). They are ideally suited for various applications in chemical processing, power generation, oil and gas, commercial marine markets, power hydraulics, lubricating systems, etc. They are also often used for transferring lubricating fluids because the screws are not geared together. Triple screw pumps can operate at full speed, which helps to minimize shear. They also do not require priming because the vacuum created between the screws enables the pump to self-prime.

Components of a triple screw pump

Electric motor

The electric motor is the source of the mechanical power that helps to operate a triple screw pump. The electric motor can run using alternating current (AC) or Direct current (DC) from the mains power supply.

Pump housing/casing

The purpose of the pump housing is to contain the pump screw assembly. It also seals off the pump interiors from the atmospheric pressure to prevent leakage and retain pressure. Tripple screw pump manufacturers use various materials such as carbon steel, cast iron, ductile iron, aluminum alloy, and stainless steel to design pump casings.

Screw assembly

The rotor is the pump’s spinning component, and it comprises the diver and driven screws and bearings.

- Diver screw- the driver screw attaches to the motor’s driving shaft. Its function is to rotate the driven screws and to help maintain a consistent volumetric flow rate of fluid pumping. Pump manufacture design diver screws using materials such as alloy steel, hardened steel, and surface treated steel

- Driven screws- the driver screws are designed to fit accurately with the drive screw. When the driven screw rotates with the drive screw, the liquid’s volume decreases, pressure increases and moves towards the outlet port where it discharges.

- Bearings- The bearings support the screws and sustain axial and radial stresses during pump operation.

Driving shaft

The purpose of the driving shaft is to link the pump assembly to the drive motor through a flexible coupling. It is held in place by a set of bearings, and it requires accurate alignment to preserve them and enhance a prolonged pump survival life.

Inlet and outlet ports

The liquid is sucked in via the inlet port and discharged via the outlet port. Tripple screw pump manufacturers tailor the inlet and outlet ports so that enough fluid remains in the suction and discharge tubes when the pump stops. This help with the delivery of the pump’s initial liquid. As such, the suction tube should not go dry.

Pressure relief valve

Positive displacement pumps, like the triple screw pump, build up a lot of pressure during operation, which may damage the pump components and injure the operator. As a result, they contain a pressure relief valve which helps to return the extra pressure to the intake, thereby safeguarding the pump and the operator

Suction filters

The purpose of the suction filter is to prevent unwanted solid particles from entering the pump.

How does a triple screw pump?

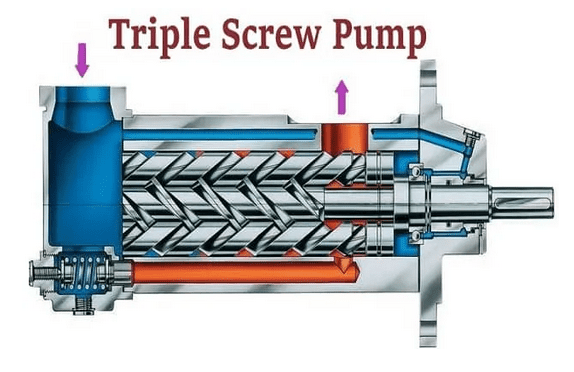

When the electric motor starts, it transmits mechanical power to the driver screw via the driving shaft and flexible coupling. As the driver screw begins to turn, it rotates the driven screws, which mesh together within the pump casing to form a sealed delivery chamber. When turning the driver screw, the sealed chamber moves axially from the suction to the pressure/discharge side according to the screw pitch. As the driver screw continues to rotate, liquid traps in the sealed chamber between the screws, compressing and moving along the axial direction from the suction side to the discharge side. The continuous and gentle meshing of the screws contributes to low shear, silent operation, and low flow pulsations. The sealed chamber moves at a constant volume and uniform speed between the casing and the three screws, allowing an even flow over the length of the pumping elements.

Figure: Tripple screw pump (three screw pump).

Types of triple screw pump

Three screw pumps can be classified as either single-suction or double-suction triple screw pumps, depending on the method of screw suction. They can also be vertical or horizontal triple screw pumps depending on the pump shaft position.

Single-suction triple screw pump

In a single-suction triple screw pump, the pumping fluid draws from one side of the screw. Triple screw pump with single suction is less expensive to acquire and maintain than double suction counterparts.

Double suction triple screw pump

This type of triple screw pump takes in fluid from both sides of the screws. The double suction design has a low negative pressure suction head requirement (NPSHR) and balanced hydraulic loads. It also eliminates axial forces and facilitates higher flows. However, the double suction triple screw pumps are more expensive than the single suction types.

Figure: Double suction triple screw pump

Vertical triple screw pump

Vertical types of triple screw pumps consist of a vertically oriented shaft. They can be directly coupled to a motor or other source of power. They usually take less floor space, have a compact structure, and are low in weight.

Figure: vertical triple screw pump.

Horizontal triple screw pump

In a horizontal triple screw pump, the driving shaft is orientated horizontally. This is the most popular version of three screw pump. They are easy to install and repair since it is easy to access internal parts of the pump.

Figure: Horizontal triple screw pump.

Applications of triple screw pump

Triple screw pumps are used in many industries, including chemical, oil, and gas extraction, marine, power plants, paper, paint, and ceramics. Their typical uses include the following:

- Triple screw pumps/ three screw pumps are used for transferring clear lubrication fluid without solid content.

- They are used for generating pressure in hydraulic systems.

- They are used for overcoming pressure in hydraulic circuits.

- They are used for pumping highly viscous liquids such as lubrication oil, hydraulic oil, engine oil, banker oil, mineral oil, oil-water emulsions, etc.

- They used in power generation.

- They are used for lubrication purposes such as gear and bearing lubrication, compressor lubrication, etc.

- They are also used for high-pressure fuel injection.

- They are also used for fuel transportation.

- They are used for lube oil delivery or injecting oil into massive equipment.

Advantages of triple screw pump

- Triple screw pumps are easy to install and maintain due to simple and compact construction.

- It can be used for nearly all fluids.

- Its operation is quiet and free of vibration and pulsation, even at high speed.

- It has a strong self-priming ability.

- A triple screw pump also has very high energy and volumetric efficiency.

- Its flow is also stable, with only minor pressure fluctuation.

- It can operate at any position, provided the pump does not run dry.

- It can pump viscous fluid without losing flow.

- It is highly reliable relative to other pumps.

- Its robust bearing design compensates for the axial loads while all radial loads are self-compensated.

- It is highly resistant to dust and water vapors.

- It can manage extremely high fluid flow rates.

- A triple screw pump can also work with low suction pressure.

- The pump is gas tolerant and can handle free and entrained gases without vapor locking or suction loss.

Disadvantages of triple screw pump

- A triple screw pump cannot run dry or pump non-lubricating liquids because they will damage its components.

- They cannot handle fluid containing solids.

- Initial installation costs can be very high for small business.

- A triple screw pump cannot apply for pumping gases because it can’t run dry.

- The pump cannot scale to low speeds below 50 cubic meters per hour.

Troubleshooting triple screw pump

Low capacity or loss of flow

- The system is restricted. Inspect valves in the suction and discharge sides. Ensure that the fluid level in the tank is as recommended by the triple screw pump manufacturer and that the non-return valve operation is regular.

- The pump speed is low. Ensure that the motor speed is correct according to the three screw pump manufacturer’s guide and that the pump is not overloaded. For belt driven pump, ensure that belt is tight and doesn’t slip.

- The motor is in reverse rotation. Ensure motor rotation direction matches the direction indicated by the pump manufacturer on the nameplate.

- Worn-out screws. Inspect and replace screws if it is necessary.

Loss of suction

- The system is blocked. Inspect suction pipes for blockage and remove any blocking material.

- The suction filter is clogged. Check the inlet filter and clean or replace.

- Viscosity is exceptionally high. Check that the fluid viscosity aligns with the triple screw pump manufacturer’s specifications.

Low discharge pressure

- Worn out screws. Inspect and replace screws, both the driver and driven, as a single set and not individually.

- The pump does not meet the net suction pressure head requirement. Increase the fluid level in the suction tank and reduce pump speed. Ensure fluid viscosity is correct for the pump.

Noise and vibration

- There is solid material ingress. Inspect the screw for solid ingress or intake particle above the pump manufacturer’s recommended sizes.

- Some pump parts are contacting. Inspect the condition of the pump shaft, casing, and bearing and correct any abnormality.

- The relief valve opening and closing rapidly. Increase the relief valve set pressure according to the triple screw pump manufacturer’s guide.

Summary

A triple-screw pump, or three-screw pump, is a rotary positive displacement pump with a pumping element consisting of three screws. One screw is the driver, while the other two serve as driven screws. An electric motor turns the drive screw, which rotates the other two screws. During operation, the drive screw and the two driven screws mesh together within the pump casing to form transfer chambers. As the screws continue rotating, the chambers move continuously and axially, moving the pumping liquid from the suction to the discharge side according to the pitch of the screws. Tripple screw Pump manufacturers design these pumps for use in many applications, including transferring clear lubrication fluid without solid content, power generation, lube oil delivery, high-pressure fuel injection, and pumping highly viscous liquids such as oils.

Significant advantages of a triple screw pump include quiet operation, free of vibration and pulsation. It is easy to install and maintain and can pump nearly every fluid with lubricating properties. However, it cannot pump fluid containing solid particles or non-lubricating liquids because they may damage its components due to high friction.