API610 BB2 Centrifugal Oil Pump

What is an API610 BB2 centrifugal oil pump?

An API610 BB2 centrifugal oil pump is designed according to BB2 pump specifications spelt out in the 10th edition of API610. It has a between-bearing (BB) type two design where the impeller is installed on a shaft supported by bearings on both sides and housed in a radially split casing. Further, API 610 BB2 pumps can have a single stage or multistage and double suction. In an API610 BB2 centrifugal oil pump, the motor is connected to the pump via flexible coupling and installed on a common base plate. The pump’s radially split casing pullout design enables easier removal of the rotor assembly without disturbing the driver, coupling hubs or casing nozzle connections. The liquid enters the chamber at the suction line pressure and exits at elevated pressure. The pump is designed for heavy-duty and is primarily used for offshore applications and oil refineries.

API610 BB2 centrifugal oil pump manufacturers design this pump with a high capacity of up to 1740 cubic meters per hour, a maximum head of 280 m, and a wide temperature range of between -45 and 450 degrees centigrade. The pump’s manufacturers also avail API610 BB2 centrifugal oil pumps in vertical and horizontal configurations.

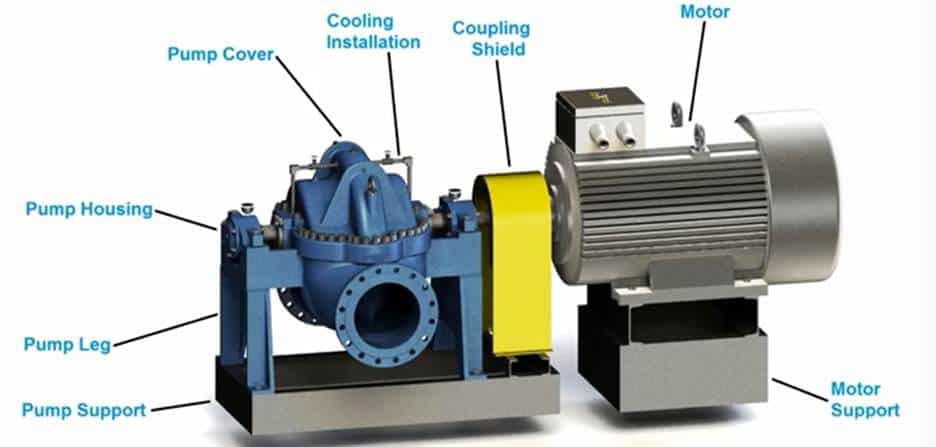

Figure: Showing the configuration of API610 BB2 centrifugal oil pump

Generally, the material used for manufacturing API610 BB2 centrifugal oil pumps must meet the grades in API 610 standards. Typical materials include carbon steel for crude oil applications and 25% Cr super duplex for seawater applications. The API610 BB2 centrifugal oil pumps can also be manufactured from duplex and in AISI 316 stai6nless steel.

Components and API610 BB2 centrifugal oil pump

Pump casing

The pump casing houses the internal pump components, such as the bearings, shaft and impeller. An API 610 centrifugal oil Pump manufacturer’s produce the casing as either axially or radially split. In an axially split casing design, the suction and discharge nozzle are cast as a single part with the lower casing half. The two halves separate horizontally or parallel to the shaft axis. Axially split casing allows easy access of pumps’ internal components but can cause pump leakage over a long time when the split line wears out and the gasket stops sealing. Radially split casing design feature a vertical joint allowing its two halves to open perpendicular to the shaft axis and parallel to the impeller. Generally, API610 BB2 centrifugal oil pumps use the radially split casing design because it prevents pump leakage at high pressure. A radially split casing also enhances impeller symmetry which eliminates axial loads.

Figure: showing radially split casing (Left) and axially split casing (Right)

Figure: Showing radially split casing of the API610 BB2 centrifugal oil pump.

Pump Shaft

The pump shaft is a rotary mechanical component supported on bearings and carrying the impeller. Its function is to rotate the impeller to displace the fluid in the pump. The pump shaft, bearing housing, sleeves and impeller constitute the rotor assembly, which connects to the electric motor through a coupling. The API 610 BB2 centrifugal oil pump manufacturers machine the pump shafts from strong materials such as stainless steel and carbon steel to withstand the heavy load, high speeds, and vibration, which can cause a large amount of stress during operation.

Impeller

The impeller is the component comprising a series of backwards-curved vanes and usually mounted on the pump shaft and housed in a watertight casing. Its main function is to displace fluid through the pump by increasing the kinetic energy and pressure of the fluid. Impellers have two types: Axial flow impeller and Radial flow impeller. The fluid flows axially to the pump shaft in axial impellers, while in a radial impeller, the fluid moves perpendicularly to the shaft. The API610 BB2 centrifugal oil pumps use radial impellers. Radial-type impellers are widely used in single and multistage split-case centrifugal pumps. The Axial impellers, on the other hand, primarily apply in high-flow and low-pressure applications.

Double suction

Most centrifugal pumps have single suction. However, single suction cannot be sufficient for applications with extremely high flow rates, such as oil transportation. An API610 BB2 centrifugal oil pump manufacturers design this pump with double suction allowing fluid to enter the pump from both sides of the impeller. It is used because the flow rate required for the API610 BB2 centrifugal oil pump is too large for an inlet cross section with single suction. The double suction also helps to increase the flow at a constant head and to minimize cavitation.

Motor

The electric motor is the source of power in API 610 BB2 centrifugal pump and is responsible for running the pump to move fluid to the required destination. The pump motor is an electromechanical device directly coupled with the pump shaft to transmit torque. It converts electrical energy from the mains electricity supply into mechanical energy and transmits the torque generated to the pump shaft via flexible coupling to rotate the rotor assembly. An electric motor has two types: an AC motor and a DC motor. An Ac motor uses alternating current, while a Dc motor uses direct current.

Figure: Components of API610 BB2 centrifugal oil pump.

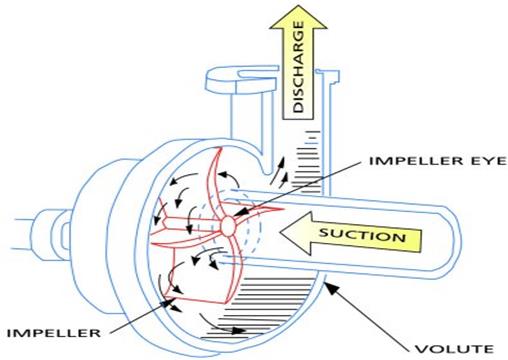

How does an API610 BB2 centrifugal oil pump work?

When the motor is powered, torque is transferred from the motor shaft to the pump shaft via a coupling. As the pump shaft begins to rotate, it turns the impeller installed on it at the same speed. The centrifugal force acting on the pump impeller creates a vacuum, allowing the fluid to move from the sump into the pump. The fluid first strikes the impeller’s eye and then splits radially outwards to the vanes, imparting kinetic energy to the fluid and increasing its velocity. The centrifugal force acting on the impeller discharges the high-velocity fluid from the impeller’s vanes into the diffuser. In the diffuser, the fluid velocity gradually decreases, and the pressure rises due to the conversion of the high-velocity head into the high-pressure head. When the fluid attains the required pressure, it discharges from the pump and transfers to the required destination via the pipe network.

Figure: Working of an API610 BB2 centrifugal oil pump.

Types of API610 BB2 centrifugal oil pump

Vertical API610 BB2 centrifugal oil pump

Vertical API 610 BB2 centrifugal oil pumps have their shafts oriented vertically or perpendicularly to the base plate. Vertical pumps take up less floor space and can handle fluid at extremely high working temperatures and pressure. Their net suction pressure head can also be altered to fit various applications. However, Vertical API 610 BB2 centrifugal oil pumps require a lot of headroom and are difficult to install and maintain as it is mostly installed in deep pits. It is also difficult to balance thrust with an overhang shaft.

Figure: Vertical API610 BB2 centrifugal oil pump.

Horizontal API610 BB2 centrifugal oil pump

API610 BB2 centrifugal oil pumps of this type feature are oriented horizontally between bearings or lying parallel relative to the base plate. Horizontal API610 BB2 centrifugal oil pumps are easier to install and maintain. They have low head requirements and are suitable for indoor applications with limited vertical space. This is the most commonly used type of API610 BB2 centrifugal oil pump.

Figure: horizontal API610 BB2 centrifugal oil pump.

Single-stage API610 BB2 centrifugal oil pump

This type comprises a single chamber containing one impeller for fluid displacement. The single-stage configuration is the simplest pump design, presenting many benefits such as stable operation, easy maintenance, lightweight, lower cost, and large flow capacity.

Figure: Single-stage API610 BB2 centrifugal oil pump.

Multistage API610 BB2 centrifugal oil pump

Meanwhile, multistage types have more than one impeller in different pump chambers. The impellers are connected in series to increase pressure at each stage. The more the number of chambers or stages, the more the output pressure energy and thus these pumps are capable of discharging fluid at extremely high pressure.

Figure: Multistage API610 BB2 centrifugal oil pump.

Applications of an API610 BB2 centrifugal oil pump

- They are used in petroleum refining and transportation.

- They are also used in refineries and the petrochemical industry to transfer products at high or low temperatures.

- API610 BB2 centrifugal oil pump is used for the crude oil transfer.

- They are also used in petrochemical and heavy-duty processing.

- They are used for domestic and industrial water supply.

- API610 BB2 centrifugal oil pumps are also widely applied in seawater desalinization and refining salt from seawater.

- They are also used in the shipyard or offshore industries.

- They can be used as boiler feed boosters and cooling water pumps.

Advantages of an API610 BB2 centrifugal oil pump

- API610 BB2 centrifugal oil pumps have high energy efficiency.

- They have a wide operating temperature range hence suitable for handling fluid at different temperatures.

- They are consistent, effective and highly reliable in operation if used according to the API610 BB2 centrifugal oil pump manufacturer’s instructions.

- The pumps are fully compliance with API610 standards.

- They are perfect for applications requiring high pressure.

- They are easy to maintain because the rotor is removable without dismantling the piping.

- Their double suction impeller construction reduces end thrust.

- They have a wide application versatility.

- They can pump oil over long distance.

Disadvantages of an API610 BB2 centrifugal oil pump

- API610 BB2 centrifugal oil pumps are complex to design and costly to acquire.

- They are subject to cavitation, damaging the impeller surfaces and pump casing.

- Vertical API610 BB2 centrifugal oil pumps require large headroom.

Troubleshooting an API610 BB2 centrifugal pump

Little or no discharge after Pump start-up

- The pump is operating in reverse. Ensure that the motor rotation direction follows the API610 BB2 centrifugal oil pump manufacturer’s guide. Reverse the motor polarities.

- There is air in the Pump or suction pipework. Check that the pump and pipe network are filled with water.

- The filter or check valve is blocked with impurities. Inspect the pump filter or check valve and remove any sediment present.

Excessive pump vibration and noise

- Large misalignment between the pump shaft and the motor shaft. Inspect and realign the shafts.

- Pump bearings or impeller is worn out. Check the bearing and impeller for wear and replace them if it is necessary.

- The pump operates in cavitation. Ensure the inlet valves are fully open, and the pump is working at the speed recommended by the API610 BB2 centrifugal oil pump manufacturer.

The pump overheats during the operation

- Poor coupling alignment. Ensure the pump is properly aligned and the coupling rubber is in place.

- The pump grease is contaminated or excessive. Ensure grease is clean, and it does not exceed the pump manufacturer’s specification.

The pump does not develop pressure

- There is no priming liquid in the casing. Ensure that pump casing is filled with the liquid.

- Leakage in the mechanical seals. Replace seals.

- Leakage in foot valve or check valve. Replace the valves.

Pump leakage at the shaft

- The mechanical seals or O-ring is worn out. Replace the seals and O-ring.

Summary

API610 BB2 centrifugal oil pump is a type of pump with a between bearings design, radially split casing, double suction and complying with the standards set out in the API610 10th edition. The API610 BB2 centrifugal oil pump’s manufacturers avail them in vertical and horizontal configurations and single-stage and multistage designs. Typical construction materials for API610 BB2 centrifugal oil pumps includes carbon steel for crude oil applications and 25% Cr super duplex for seawater applications.

API610 BB2 centrifugal oil pump manufacturers produce these pumps for use in applications such as petroleum refining and distribution in offshore refineries, chemical processing, and transferring fluid under a wide range of temperatures and pressure. Pump manufacturers design these pumps for high-performance characteristics such as high capacity (up to 1740 cubic meters per hour), high maximum head (up to 280 m), and a wide temperature range (between -45 and 450 degrees centigrade). API610 BB2 centrifugal oil pumps are highly energy efficient, they are double suction, reliable, and simple to maintain and have wide application versatility.