High-Pressure Electric Water Pump

What is a high-pressure electric water pump?

A high-pressure electric water pump is a type of centrifugal pump used to increase water pressure and flow rate to move it from various sources to a storage tank or water outlet. It is usually electrically powered via electric motor. The high-pressure electric water pump manufacturers design the devices to alleviate the problem of low water pressure, which can be frustrating even for minor domestic tasks such as showering, filling tanks, etc. This device features a pressure switch or flow control device that helps maintain the correct pressure and water volume flow level. Some high-pressure electric water pumps utilize a pump pressure switch to ensure more effective flow management around the cut-off pressure. The high-pressure electric water pump is ideal for domestic and agricultural applications requiring increased water pressure and high flow rates. Typical applications include pumping water from a rain harvesting tank and increasing water pressure for irrigation systems.

Figure: High-pressure electric water pump

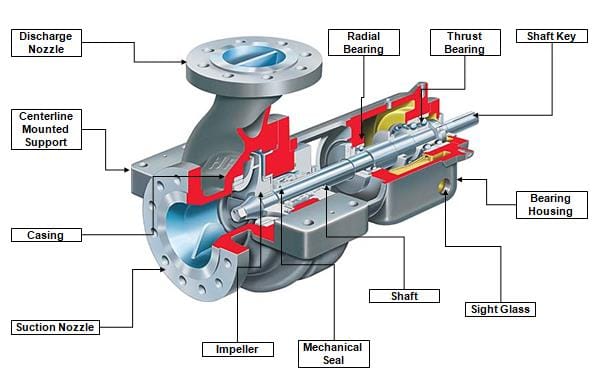

Components of a high-pressure electric water pump

Motor

The high-pressure electric water pump uses an alternating current (AC) single-phase induction motor. The electric motor is close-coupled to the pump head in most high-pressure electric water pumps. Electric motor provides mechanical energy for rotating the pump impeller.

Pump casing

The pump casing house the pump’s internal components and helps to convert the high kinetic energy (imparted on the water by the impeller) into a pressure head. The high-pressure electric water pump manufacturers create the pump casings from ductile cast iron, cast steel, or stainless steel.

Shaft

The shaft is a rotary cylindrical mechanical component centrally located in the pump and riding on bearings. It supports the impeller and connects the pump rotor assembly to the motor through coupling. It is usually made of stainless steel to overcome corrosion and mechanical vibrations.

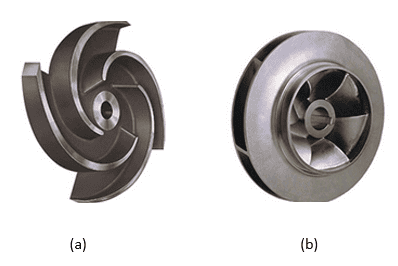

Impeller

The impeller features a series of backward-curved vanes and is usually mounted on the pump shaft. It displaces the fluid that comes in through the pump inlet and exits through the outlet. The impeller can be either an open-type or a closed-type impeller. The open-type impeller has vanes that are open on both sides without any protective shroud. On the other hand, a closed-type impeller consists of a back and front shroud, which enclose the vanes, providing maximum strength. It has a low NPSH requirement and is more efficient.

Figure: Types of radial flow impeller; a) open impeller, b) closed impeller.

Inlet and outlet

The pump inlet connects with the waterline while the outlet connects to the household water distribution piping

Pressure or flow-sensing devices

The pressure flow sensing devices help to measure the pressure and flow rate of the fluid moving through the pump and to adjust accordingly.

Figure: Components of a high-pressure electric water pump.

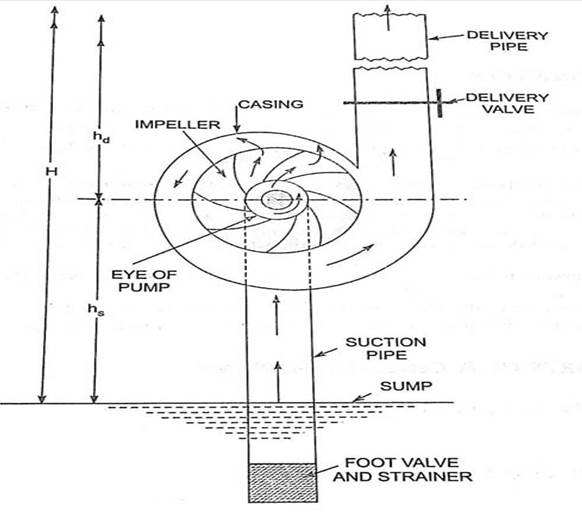

How does a high-pressure electric water pump work?

A high-pressure electric water pump converts the mechanical energy of an impeller into kinetic energy and then the pressure energy of water. The impeller is directly coupled to the electric motor drive shaft and spins at motor RPM. As the impeller rotates, it creates a vacuum inside the pump, allowing the water to flow into the pump casing under the external atmospheric pressure. When the water strikes the impeller vanes, it is imparted with high kinetic energy and accelerated towards the pump casing due to the centrifugal force acting on the impeller. In the pump casing, the water speed slowly decreases due to the gradually reducing flow path size, and the high kinetic energy converts into a high-pressure head. Finally, the water leaves the pump casing through the pump outlets and enters the delivery pipe to be transferred to the desired location.

Figure: Working of a high-pressure electric water pump

Types of a high-pressure electric water pump

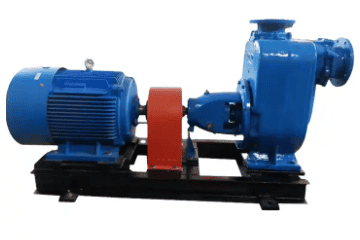

Self-priming high-pressure electric water pump

This is the type of pump designed with features that support self-priming capabilities. High-pressure electric water pump manufacturers design the pump to have a reservoir that holds water for priming. The pump creates a vacuum inside which moves water inside and thus moves air and water mixture to the discharge. Air has low density relative to water and thus, the air is expelled while returns back to the pump via gravity. The process repeats until all the air is expelled after which normal pumping process starts.

Figure: Self-priming high-pressure electric water pump.

Single-stage high-pressure electric water pump

A single-stage high-pressure electric water pump has only one impeller that pressurizes and displaces water through the pump. It is the most straightforward construction of a high-pressure electric water pump. It is cheaper relative to multistage pump and its head is relative lower.

Figure: Single-stage high-pressure electric water pump.

Multistage high-pressure electric water pump

A multistage high-pressure electric water pump consists of more than two impellers in different pump chambers mounted in series. Water enters the first chamber at suction pressure, and as it advances to the subsequent stages, the pressure increases while the flow rate remains constant. The multistage high-pressure electric water pump can work with a smaller motor and manage higher pump head and flow rates than the single-stage counterpart.

Figure: Multistage high-pressure electric water pump

Stainless steel high-pressure electric water pump

The stainless-steel high-pressure pump features a complete stainless-steel construction of all wetted components to protect against corrosion. It is usually created for horizontal mounting, allowing for coupling with electric motor. The pump is easier to install and maintain because the spacer coupling provides space for a maintenance operation, and the pump’s internal components are easily accessible. It suits heavy-duty applications because it can generate higher fluid pressure and flow rates. Because of the horizontal orientation, this unit is perfect for indoor applications where vertical space is confined.

Figure: Stainless steel high-pressure electric water pump.

Applications of high-pressure electric water pumps

High-pressure electric water pumps are extensively used in domestic, agricultural, and industrial applications because they provide a wide range of water pressure and flow rates. Typical uses of high-pressure electric water pumps include:

- High-pressure electric water pumps are used to bring out water from the water/rain harvesting tank

- They are used to Increase the water pressure and flow rate in domestic commercial and industrial water supply systems.

- They are used to boost water pressure due to the low supply of city water.

- They are used to feed water to industrial apparatus that might require high volumes of water at a higher pressure for various applications, such as shower blocks, portable toilets, etc.

- They are used to push water from ground levels up multiple levels.

- They are also used to increase water pressure for irrigation systems

- They are also used for pumping water from an alternative water source such as a river, pond, or stream.

Advantages of a high-pressure electric water pump

- High-pressure electric water pumps have a simple and compact construction, requiring relatively small installation space.

- They have high reliability and efficiency.

- They provide cavitation-free operation.

- A high-pressure electric water pump provides a continuous and steady flow output.

- They have low power consumption, helping with energy conservation.

- They are cheap and easy to acquire.

- A high-pressure electric water pump can handle a wide range of pressure and flow rates.

- They do not have pressure losses.

- They have Low life cycle costs due to minimal maintenance requirements.

Disadvantages of a high-pressure electric water pump

- The high-pressure electric water pump requires a strict balance between the water flow rate. If the water flow rate in the mainline exceeds the pump’s capacity, the pump may over speed or become ineffective.

- The pump may corrode due to seal leakage above the pump casing.

- High-pressure electric water pumps are subject to mechanical seal damage due to gas accumulation in the seal chamber.

- The pump may fail under extreme loading conditions.

Troubleshooting a high-pressure electric water pump

The pump does not start

- There is a blown-out fuse or tripped circuit breaker. Inspect the high-pressure electric water pump for a blown-out fuse and replace it if necessary.

- The power supply to the panel is insufficient. Ensure that the voltage and current supply to the pump match the amount specified in the high-pressure electric water pump manufacturer’s manual.

- The fuse receptacles are dirty or corroded. Inspect and clean fuse receptacles if necessary.

- The voltage is irregular due to dirt or corrosion at the pressure switch. Inspect the pressure switch and clean it of any debris or pollution.

The pump loses its prime after starting

- There is an excessive amount of air in the liquid. Make sure you locate any points of air leakage and seal them, e.g., air entering the pump via the suction joints.

- The suction lift is too high. Reduce the suction lift by lowering pump elevation or increasing the water level.

- The water seal pipe is clogged. Clean or change the water seal pipe.

The pump has a low capacity

- The pump or suction pipe is not filled with water. Inspect the foot valve for leakage and correct it.

- There is air pocked in the suction line. Ensure that the pipe is filled with the pumped liquid. Avoid negative suction by eliminating any concentric.

- The total head of the pumping system exceeds the pump’s design pressure head. Measure the pump head using a pressure gauge. Refer to the high-pressure electric water pump manufacturers’ manual for the pump’s design pressure head.

- The pump impeller is clogged. Inspect the impeller and remove any clogging material.

- The pump is operating in reverse. Ensure that the direction of the motor rotation matches the direction indicated by the high-pressure electric water pump manufacturers on the pump’s nameplate. Be sure to reverse the motor polarities if necessary.

The pump is noisy, or it vibrates excessively

- There are foreign materials in the pump. Disassemble the pump and clean any foreign matters.

- There are unbalanced components in the pump. Inspect and rebalance the elements.

- The pump’s foundation is not rigid. Check vibration and hollowness on the base frame.

- The pump assembly is loose. Tighten pump components to the torque level recommended by high-pressure electric water pump manufacturers.

- The impeller is worn-out. Inspect the impellers and replace any worn-out impeller with another one from the high-pressure electric water pump manufacturer.

The pump overheats and seizes

- The viscosity of the liquid is different from the design. Ensure the pump applies to the correct fluid following the high-pressure electric water pump manufacturer’s manual and product data sheet.

- There is a mechanical failure inside the pump, causing too much thrust. Inspect the pump assembly and correct any shortcomings.

- The pump is not primed. Fill the pump casing with water to drive out air from the air cock.

- The pump bearings are worn-out. Inspect and replace the bearings if necessary.

- Rotating parts are rubbing on the stationary part. Disassemble the pump and correct the assembly.

Summary

A high-pressure electric water pump is a particular type of centrifugal pump for transporting water at high pressure and high flow rate from a source to a storage tank or a water outlet. It is designed to be electrically powered using electric motor. High-pressure electric water pump manufacturers create this device to alleviate the problem of low water pressure in pumping systems. High-pressure electric water pumps use a pressure switch or flow control to maintain the desired amount of pressure and volume flow of water. Some variants of high-pressure electric water pumps consist of a pressure switch to provide more effective control around the cut-off pressure.

These pumps suit domestic, agricultural, and industrial applications that require water supply at high pressure and high flow rates. Typical uses of high-pressure electric water pumps include pumping water from a rain harvesting tank and increasing water pressure for irrigation systems. High-pressure electric water pumps are simple, compact, highly efficient, and reliable. They also have Low life cycle costs due to minimal maintenance requirements.