Inline Sewage Pump

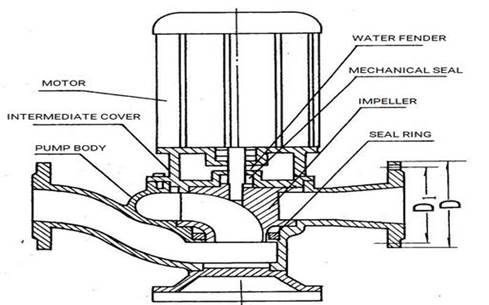

Components of an inline sewage pump

Pump body or housing

The pump body or housing supports and protects most of the pump interval components, including the shaft, bearings, impeller, shaft sleeve, etc. The pump housing is usually sealed to retain pressure and protect against leakage. It houses vital parts of the pump. The pump housing also features the inlet and outlet flanges that guide the fluid into the pump at suction pressure and out of the pump at higher pressure.

Motor

The function of the motor is to spin the pump impeller or simply to run the pump. It works by converting electrical energy into mechanical energy. An electric motor can be either an AC motor or a DC motor. Ac motors work with alternating current, while Dc motors operate with direct current.

Shaft

The is a rotary mechanical component supported by the bearing and carrying the impeller. Its function is to rotate the impeller to displace the fluid in the pump. The pump shaft, bearing, and impeller form the rotor assembly, which connects to the electric motor through a coupling. In an inline sewage pump, the motor shaft carries the pump impeller i.e., the shaft is closely coupled to the pump impeller.

Impeller

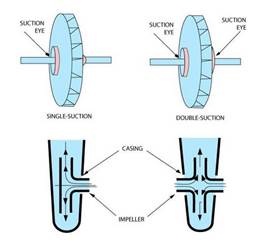

The impeller moves fluid that comes in through the pump inlet and exits through the outlet. Inline sewage pump manufacturers can design impellers in either axial flow design, where the fluid flows axially to the shaft, or radial flow design, where fluid flows radially to the shaft. Radial flow impeller can have either an open or closed impeller design. Open impellers have only one shroud, and the vanes are exposed on one side. They are mainly used in single-stage, single-suction centrifugal pumps. A closed impeller has a cover on either side; the impeller vanes are sandwiched between the two shrouds. Closed impellers are mostly used in radial flow centrifugal pumps and can have a single or double suction configuration. An inline sewage pump employs an open impeller because it can efficiently handle large amounts of suspended bodies and fluids with high viscosity.

Figure: Showing closed impellers: single and double suction configurations.

Bearings

The bearings carry the rotor assembly and ensure that it aligns perfectly with the pump body. They carry the fully rotary load of the shaft during operation and minimize friction between the rotating shaft and the stator for smooth operation.

Mechanical seals

The mechanical seals serve to prevent fluid under pressure from leaking out of the pump. Mechanical seals also prevent the pump from drawing in the air under vacuum conditions.

Pump Inlet and outlet

The pump inlet connects with the waterline while the outlet connects to the household water distribution piping. The pumping medium enters the pump through the inlet section and discharges via the outlet section.

Technology Parameters:

Flow:8-2600m3/h;

Head:5-60m;

Power:0.75-250kw;

Rotary speed :580-2900r/min;

Calibre:25-500mm;

Temperature:≤60℃。

Troubleshooting

The inline pump zero discharge after startup

- The inline pump operation is reversed. Ensure that the direction of the motor rotation matches the direction indicated by the inline sewage pump manufacturer using the arrow in the nameplate. Reverse the motor polarities

- There is air in the pump or suction pipework. Fill the pump or pipework with water to drive out the air from the pump system.

- The impeller or check valve is clogged. Inspect and clean any blockage in the valves

- The monomeric head is insufficient due to high friction losses that exceed the pump design. Increase the pump power. Make sure the pipes used in the piping network meet the recommended diameter by the inline sewage pump manufacturer.

Inlet pump experiencing excessive vibration

- Some pump components are unbalanced. Inspect and rebalance parts if necessary.

- The pump impeller is partially clogged. Inspect and clean the impeller.

- The impeller is severely worn out or defective. Inspect and replace the impeller.

- Some pump components are loosely held within the pump body. Tighten any loose parts to the torque level recommended by the inline sewage pump manufacturer.

The noise level is too high

- There is air in the liquid. Ensure that the suction pipe is completely submerged to prevent the formation of vortexes on the surface of the liquid

- Pump working in cavitation. Check that the suction line valves are fully open.

- The pump is working outside the duty range. Ensure the correct duty range according to the inline sewage pump manufacturer’s manual.

The Inlet pump driver overloaded

- The Pump speed is too high. Reduce the pump speed.

- Faulty pump motor. Inspect the motor for defects and repair or replace it if necessary.

- Some pump parts are subject to extreme mechanical friction. Inspect the pump assembly for any obstruction or deflection and correct it.