API610 OH3 and OH4 Coupled pump

What is API 610 OH3 and OH4 coupled pumps?

API 610 OH3 and OH4 coupled pumps are vertical inline, single-stage pumps with an overhung impeller and a coupling on the motor and pump shafts. These pumps are designed according to the specifications in API610 10th edition. API 610 OH3 and OH4 coupled pumps are called overhang (OH) pumps because their impellers overhang a radial bearing, which supports and balances all forces, including the overhung mass and the rotor dynamic and hydraulic forces. They feature a vertically oriented pump shaft, a single impeller, and a coupling between the motor and pump shafts. Their coupling design allows easy removal of the back pull-out assembly without disturbing the driver, coupling hubs or casing.

API 610 OH3 and OH4 coupled pump manufacturers design these pumps for various applications such as power generation, gas processing, water treatment, chemical processing among others. The pumps have high-performance capabilities with a max flow rate exceeding 1100 cubic meters per hour, a maximum speed of up to 3000 rpm, a wide operating temperature range ( -15 to 400-degree centigrade), maximum pressure of up to 5Mpa, and a max head of about 380 m.

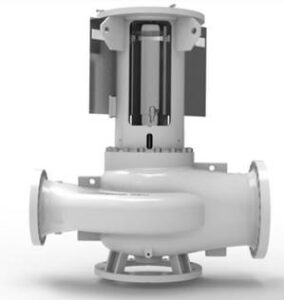

Figure: The configuration of an API 610 OH3 coupled pump

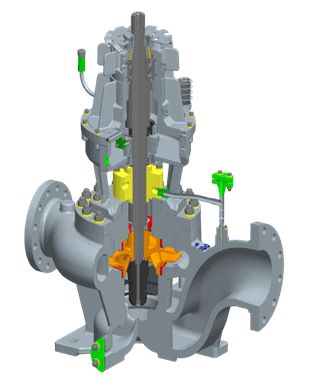

Figure: The configuration of an API 610 OH4 coupled pump

The main difference between the API 610 OH3 and OH4 coupled pumps is found in the coupling design. The API 610 OH3 pump consists of a flexible coupling between the motor and the pump shafts. A flexible coupling is designed to accommodate small angular and parallel misalignment. It helps to reduce vibration and prolong the working life of the pump. On the other hand, API 610 OH4 coupled pump comprises a rigid coupling connecting the pump and the motor shaft. The rigid coupling does not allow any shaft misalignment because the shafts must be rigidly bolted together, requiring precise shaft alignment.

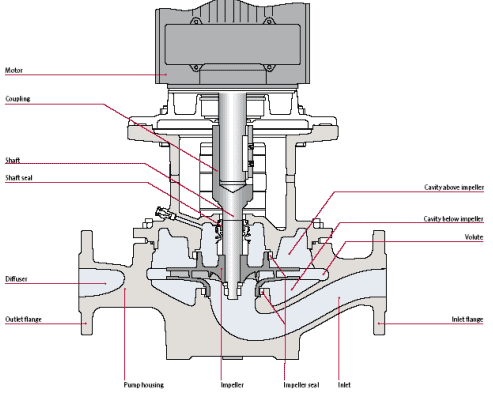

Components of API 610 OH3 and OH4 coupled pump

Motor

The motor provides the mechanical power to run the pump impeller. An electric motor operation is based on either alternating current (AC) or direct current (DC). The API 610 OH3 and OH4 coupled pumps use an AC induction motor that is completely fenced. This kind of motor is simple and compact in construction, cheap, and maintenance-free.

Shaft

The pump shaft is a component of the rotor assembly. It carries the impeller and transmits the drive torque required to pump the liquid. Pump manufacturers design the pump shaft so that the rotor assembly centers within the bores of the pump casing to avoid any damage when the pump is running. API 610 OH3 and OH4 coupled pump manufacturers use stainless steel and carbon steel to design shafts.

Coupling

The coupling is the component linking the motor and the pump shafts. The purpose of the coupling is to transmit drive torque from the motor shaft to the pump shaft. Couplings can be flexible or rigid type. A flexible coupling allows minor angular and parallel misalignment, while a rigid coupling requires precise shaft alignment, and any misalignment will negatively impact the pump’s performance and service life.

Impeller

The impeller is the component containing backwards curved blades and riding on the pump shaft. Its primary function is to provide the centrifugal force to move the fluid axially and radially. The impeller blades impart kinetic energy to the liquid and increase the fluid velocity. Pump manufacturers use close-grained cast iron or cast steel to create an impeller. The number of impellers in a pump depends on the pump stages. Since API 610 OH3 and OH4 coupled pumps are single-stage pumps, they only consist of a single impeller. Pump manufacturers classify impellers based on the flow direction, suction type, and constructional geometry.

Pump casing

The purpose of the pump casing is to house the pump rotor assembly and seal off the pump interiors from the atmospheric pressure, which helps to prevent pump leakage and retain pressure. The pump casing contains inlet and outlet nozzles, which direct the pumping fluid into and out of the pump. API 610 OH3 and OH4 coupled pump manufacturers design this casing such that it can reduce kinetic pressure of the fluid while it increases the pressure energy responsible for transporting the fluid to the required location.

Suction and discharge pipes

The suction pipe allows the fluid into the pump while the discharge pipe directs the pumping fluid out of the pump and to the required destination. Suction and discharge pipes are attached to the pump casing via flanges or pipe unions.

Figure: Components of API 610 OH3 and OH4 coupled pump

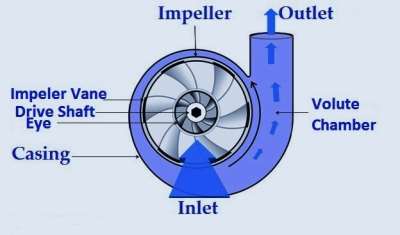

How does API 610 OH3 and OH4 coupled pump work?

When the API 610 OH3 and OH4 coupled pumps are powered, the impeller rotates, creating a vacuum inside the pump casing. Since the atmospheric pressure outside the pump casing is greater than the pressure inside, the pumping fluid is sucked through a suction nozzle and directed into an annular channel. As the impeller continues to rotate, the impeller blades impart great kinetic energy and velocity to the fluid. When the fluid has successfully passed through the impeller area, it enters the volute chamber where the high velocity is converted into a high-pressure head. The fluid then discharges through the outlet valve and discharge pipe network to the desired area. The volute chamber design is such that the cross-section progressively decreases towards the delivery side to ensure smooth energy conversion and to reduce turbulence and shock waves. Using diffuser vanes of appropriate shape on the inner periphery of the pump casing may also help to eliminate shock waves and turbulence.

Figure: Working of API610 BB3 double suction split case pump

Types of API 610 OH3 and OH4 coupled pump

The API 610 OH3 and OH4 coupled pump can have either a long-coupled design or close coupled design.

Long-coupled types

The API 610 OH3 and OH4 long-coupled pump comprise separate bearing brackets attached to the pump housing with the motor sitting on a support frame, baseplate or within the pipeline. They require careful coupling alignment when assembled and after installation in the field.

Figure: API 610 OH3 and OH4 long-coupled pump.

Close coupled types

In API 610 OH3 and OH4 close-coupled pumps, the pump impeller is directly connected to the motor shaft, with all forces being taken care of by the bearings in the motor. The close coupling design eliminates shaft alignment.

Figure: API 610 OH3 and OH4 close-coupled pump.

Applications of API 610 OH3 and OH4 coupled pump

- API 610 OH3 and OH4 coupled pumps are used in oil and gas industries.

- They are used in petroleum processing facilities.

- They are used in gas processing.

- They are used for hydrocarbon and crude oil transportation.

- They are also used in petrochemical industries

- They are perfect for offshore installations.

- They are widely used in water treatment plants.

- API 610 OH3 and OH4 coupled pumps are used in chemical processing.

- They are used in firefighting applications.

- They are used as pressure boosters in high-pressure boilers.

- They are used as feed water pumps.

- They are used for district heating.

- API 610 OH3 and OH4 coupled pumps are used in food processing plants.

- They are also used for agricultural irrigation and tank farm booster.

Advantages of API 610 OH3 and OH4 coupled pump

- API 610 OH3 and OH4 coupled pumps have simple and compact design.

- They are simple in construction and easy to operate.

- They have high power efficiency.

- They have low initial installation and maintenance cost.

- Its construction design allows dismantling without removing the pump from the piping system.

- Their running cost is relatively low.

- Their operation is silent, with only small vibration, because the vertically oriented shaft balances all the forces. Further, gravity is never pulling with or against the direction of rotation. Therefore, any rotor imbalance remains much less pronounced in vertical inline pumps.

- They can deliver a large volume of water compared to their size.

Disadvantages of API 610 OH3 and OH4 coupled pump

- API 610 OH3 and OH4 coupled pumps’ vertical installation requires high headroom for installation and maintenance.

- They are subject to high-stress concentration because the weight accumulates below the volute.

- They may experience mechanical seal failure or dry out due to infiltration and accumulation of gases in the seal chamber.

- They are prone to corrosion due to seal leakage above the pump.

- They easily trap air in the volute which can interfere with the proper working of the pump.

- They are non-self-priming, meaning they cannot drive out air from the system. If the pumps run with air inside the casing, they may damage the impeller due to air binding.

Troubleshooting API 610 OH3 and OH4 coupled pump

The pump does not prime

- There is no priming water in the casing. Ensure the casing is filled with water.

- Leakage from mechanical seals. Inspect and replace the seal with the seal recommended by the API 610 OH3 and OH4 coupled pump

- The suction line or valve is closed. Fully open the valve.

- Leaks from the foot valve or check valve. Inspect and replace them if it is necessary.

The pump does not run

- Motor is shorted out. Replace the motor with as recommended by API 610 OH3 and OH4 coupled pump

- Thermal overload has an open circuit. Consult the pump manufacturer to determine the reasons for overload, and allow the pump to cool and restart.

- The motor is poorly wired. Check the motor wiring against the pump manufacturer’s guide.

The pump fails to develop pressure or deliver water

- The discharge line is closed, and priming air cannot exit the pump. Open the discharge line.

- Leakage in foot valve, check valve or mechanical seals. Inspect and replace the valves and mechanical seals if it is necessary.

- The pump is down. Inspect and replace worn-out components with the pump manufacturer’s recommended parts.

The motor overheats and shuts down

- The motor voltage does not match the power supply voltage. Inspect the motor connection against the wiring diagrams provided on the motor nameplate. Ensure the supply voltage meets API 610 OH3 and OH4 coupled pump manufacturer’s specifications.

- The impeller is rubbing against the pump casing. Disassemble the pump, realign the rotor or replace the impeller.

- The voltage supply to the motor is low. Inspect and tighten the electrical connections. Also, correct the voltage supply.

Pump loses suction

- The suction lift is too high. Reduce suction lift to the limit specified by the pump manufacturer. Install the foot valve and prime the pump.

- Defective or clogged foot valve. Inspect and replace if necessary.

- Air leak in the suction line. Repair the suction line.

Summary

API 610 OH3 and OH4 coupled pumps are vertical inline, single-stage, overhang pumps complying with all API 610 requirements, 10th edition. They consist of a vertically oriented pump shaft, a single impeller, and a coupling between the motor and pump shafts. Their impellers overhang a radial bearing which supports and balances all forces hence the name overhang (OH) pumps.

API 610 OH3 and OH4 coupled pump manufacturers design these pumps to fit many applications such as gas processing, water treatment, chemical processing, pressure boosting, feed water pump, district heating, food control, hydrocarbon transfer, and crude oil transportation. These pumps have high-performance characteristics with a maximum discharge rate of 1100 cubic meters per hour, a maximum speed of 3000 rpm, and a head of about 380 meters. An API 610 OH3 coupled pump uses a flexible coupling, while the API 610 OH3 coupled pump uses a rigid coupling. The pump manufacturers tailor pump couplings to facilitate easy removal of the back pull-out assembly without interfering with the driver, coupling hubs or casing. These pumps have simple and compact design, high energy efficiency, silent operation, low running cost and are easy to operate. However, they require a large vertical clearance for installation and maintenance and they can easily trap air within the pump casing.