Double Suction Split Case Pump

What is a double suction split case pump?

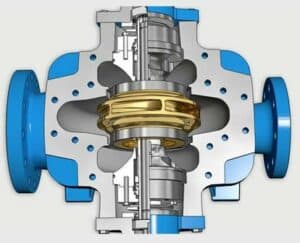

A double suction split case pump is an essential form of centrifugal pump that comprises a double suction impeller to suck the pumped medium from both ends of the impeller and then merge the flow into a volute right at the middle of the impeller. The double suction impeller is equivalent to two single suction impellers of the same diameter mounted back-to-back and working simultaneously. The flow doubles under the same outer diameter of the impeller. The double suction split case pump manufacturers develop the device with a horizontally or vertically split casing, facilitating easy dismantling, inspection, and maintenance. Further, it has the inlet and outlet oriented in a straight line, which eases the arrangement and installation of the pump and the water inlet and outlet pipes. The double suction split case pump is primarily used for transferring water and is widely preferred for water engineering systems because it runs smoothly and provides high lift and large flow.

Figure: double suction split case pump

Components of a double suction split case pump

Electric motor

The double suction split case pump can work using an alternating current motor, either a single-phase or a three-phase induction motor. The electric motor supplies the mechanical power to run the pump. It is an electromechanical device that converts the electrical energy supply into mechanical torque output to turn the rotor.

Casing

The casing is the largest stationary component of a double suction split case pump whose purpose is to house the rotor assembly and suction and discharge ports. The pump casing also contains the liquid and directs the flow in and out of the pump via the suction and delivery nozzles. The pump casing is usually sealed to retain pressure and to prevent the pumped liquid from leaking under pressure. In a double-suction split case pump, the housing is divided into two chambers held together by bolts. The joint between the two halves can be either vertical or horizontal, giving rise to two main types of split casing: vertically split and horizontally split case, as shown below.

Figure: Showing a horizontally split pump casing.

Figure: Showing a vertically split pump casing.

Coupling

The double suction split case pump manufacturers usually prefer a long coupling for the pump because it allows quick disassembly and maintenance. The long coupling connects the rotating pump shaft to the motor drive shaft, facilitating the transfer of mechanical torque to the pump head with minimal losses.

Shaft

The shaft is a solid rotary mechanical component supported on bearings and usually connected to the electric motor via a rigid or flexible coupling. Its main functions are to carry the impeller. It is commonly made from high-grade stainless steel and alloy steel to resist corrosion and vibrations.

Impeller

The primary function of an impeller is to displace water through the pump by increasing its kinetic energy and pressure. The double suction pump employs a particular type of closed impeller known as a double suction impeller. The doubles suction impeller features two back-to-back impellers designed as a single unit, and the whole rotor component rides on a shaft that suspends between two bearings for adequate support. It allows water to enter from either side simultaneously, and the flow merges at the middle of the impeller and discharges into a volute. The double suction impeller offers excellent rigidity, high hydrodynamic efficiency, and anti-cavitation ability. It can be manufactured from bronze, cast iron, and carbon steel.

Figure: Showing the design and assembly of a double suction impeller

How does a double suction split case pump work?

When the double suction split case pump is started, the pump shaft drives the impeller to rotate at the motor RPM, forcing the pre-filled water between the blades to turn at high speed. As the water is thrown radially outwards from the impeller’s eye to the outer periphery, a low-pressure zone is formed, and more water is sucked into the center of the impeller due to the external atmospheric pressure acting on the surface of the water at the source. Once the water strikes the impeller, the centrifugal force acting on the impeller blades moves it radially from the center of the impeller to the outer periphery. The swirling flow at the exit of the impeller then enters into the diffuser, where the extreme fluid flow speed decreases due to the gradual expansion of the flow passage, and the high kinetic energy converts into static pressure energy. Finally, the water discharges from the pump under elevated pressure and flows to the designated location through the discharge port and piping network.

Types of double suction split case pumps

Horizontal double-suction split case pump

The horizontal doubles-suction split case pump consists of a shaft placed horizontally within the pump. In most cases, the horizontal double-suction split case pump features a between-bearing design where the pump shaft suspends between bearing on either end to support the rotor and generate high suction pressure effectively. This pump can be coupled securely with external accessories such as turbines, electric motors, or fuel-powered engines. It has low headroom requirements; hence suitable for indoor installation where vertical space is often tight. However, it takes up more floor space and has A Low Net Positive Suction head (NPSH).

Figure: Showing a horizontal double suction split case pump.

Vertical double-suction split case pump

The vertical double-suction split case pump has a vertically oriented shaft with a radially split and overhang design. It takes up less floor space and is, therefore, perfect for installations in places with restricted surface area. In addition, it has variable NPSH to cater to a broader range of applications.

However, it requires ample vertical clearance for installation, and the overhand shaft poses challenges in balancing axial thrust at high suction pressure.

Figure: Showing a vertical double suction split case pump.

Applications of double suction split case pumps

Double suction split case pumps mostly suit water supply systems, agricultural irrigation, water conservancy projects, construction industry, water engineering works, and drainage in mines, cities, and power stations. Their typical uses include:

- Double suction split case pumps are used in domestic and industrial water supply systems to move water at high pressure and flow rate.

- They are used to support firefighting equipment.

- They transport clear water and unsaturated wastewater from industrial processes at average heads.

- They are used to supply plant makeup water and cooling water.

- They discharge wastewater from mines and drainage pumping stations.

- They are used as booster pumps in booster stations.

- They are used to supply a large flow of water to sprinkler systems in farmland irrigation.

Advantages of a double suction split case pump

- A double suction split case pump is perfect for applications requiring a large water flow and stable operation.

- It has a strong cavitation resistance due to reduced flow speed at the inlet.

- It provides a smooth operation.

- It has high capacity and high pressure.

- The split casing design facilitates easy pump disassembly and maintenance.

- It is simple and compact; the small size and weight are space-saving and easy to install.

- It has high volumetric and hydrodynamic efficiency.

- It is highly versatile in application, with uses in industrial water supply, firefighting, and agriculture.

- It provides a steady and continuous output.

- It sucks water from both sides of the impeller, creating a hydrodynamic symmetry, which provides a balanced axial thrust around the impeller.

Disadvantages of a double suction split case pump

- A double suction single split pump requires more sealing. Hence, it is relatively expensive.

- It cannot handle high-viscosity fluids and liquids containing large suspended particles.

- It is subject to mechanical seal problems; leakage in the mechanical seal can lead to corrosion of the pump component.

- A vertical double-suction split case pump requires more headroom for installation, and its weight falls below the casing, causing stress concentration.

Troubleshooting a double suction split case pump

The motor fails to start

- The motor is poorly installed. Consult a licensed pump dealer to inspect the motor installation against the double suction split case pump manufacturer’s installation guide and correct any shortcomings.

- The motor is defective. Inspect and replace the engine if it is necessary.

- The power supply to the panel is insufficient. Ensure that the motor receives the right amount of voltage and current.

- There is a tripped circuit breaker or a blown-out fuse. Inspect and reset the circuit breaker if necessary. Inspect the pump for a blown-out fuse and replace it.

The pump gives out low discharge

- The pump is running in reverse. Ensure that the motor rotates in the direction indicated by the double suction split case pump manufacturer using the arrow on the pump casing. Be sure to reverse the motor polarities.

- There is air in the pump or suction pipework. Be sure to fill the pump or piping network with water to drive out the air.

- The monomeric head is insufficient due to extreme friction losses, exceeding the pump design. Increase the pump power. Ensure the pipes used in the piping network meet the diameter recommended by the double suction split case pump manufacturer.

- The impeller or check valve is clogged. Inspect and clear any blockage in the valve or impeller.

The noise level is too high

- Some foreign materials are present in the double-suction split case pump. Disassemble and clean the pump inside.

- The mounting plate and the foundation lack sufficient rigidity. Reinforce the foundation, and mount the double suction split case pump tightly.

- The impeller is damaged or worn out. Inspect and replace the impeller.

- Pump working in cavitation. Check that the suction line valves are fully open.

- The pump is working outside the duty range. Ensure the pump’s duty range is correct following the double suction split case pump manufacturer’s specifications.

The pump is experiencing excessive vibration

- Some pump components are unbalanced. Inspect the double suction split case pump for unstable parts and rebalance them as necessary.

- Some pump components are loosely mounted in the pump body. Tighten any loose parts to the torque level recommended by the double suction split case pump manufacturer.

- The pump shaft is oblique or unbalanced. Inspect the post, rebalance it as required, or replace it.

- The pump impeller is partially clogged. Inspect and clean the impeller.

- The pump shaft is oblique or unbalanced. Inspect the component and rebalance it as required or replace it.

The pump’s driver is overloaded

- Faulty pump motor. Inspect the engine for defects and repair or replace it if necessary.

- Some pump parts are experiencing extreme mechanical friction. Inspect the pump assembly for any deflection or obstruction and correct it.

- The Pump speed is too high. Ensure the pump operates within the speed range specified by the double suction split case pump manufacturer.

Summary

A double suction split case pump is a particular model of centrifugal pump that features a vertically or horizontally split casing and a type of closed impeller known as a double suction impeller. The double suction impeller is equivalent to two single suction impellers arranged back-to-back to draw water from both ends simultaneously and then merge the flow into a volute right at the middle of the impeller. The double suction split case pump manufacturers develop the device with a split casing design to allow quick dismantling, inspection, and maintenance. The double suction split case pump also has the inlet and outlet oriented in a straight line, simplifying the arrangement and connection of the pump and the water inlet and outlet pipes. It is primarily used for transferring water and caters to various applications, such as water engineering systems, agricultural irrigation, and water conservancy projects. Generally, a double suction split case pump provides many benefits, including steady and continuous output, cavitation-free operation, and high efficiency.