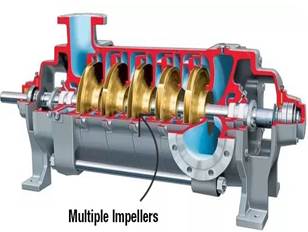

Horizontal Multistage Centrifugal Pump

What is a horizontal multistage centrifugal pump?

A horizontal multistage centrifugal pump is a type of pump that is installed in the horizontal orientation in a horizontal plane. The motor is installed on the same horizontal plane as the pump. The pump and motor design can have a close coupled design; that is motor and pump are connected without a coupling. The other option is through a long coupled design using a coupling. The working principle of this pump is based on the centrifugal force produced when the pump impeller rotates at high speed. Horizontal multistage centrifugal pump manufacturers design the pump with more than one impeller. Due to the multiple impellers used in this, it has several stages of pressure generation. Each impeller serves as a stage for the fluid flow. The more impellers, the higher the pressure the pump will produce. Applications of this pump include water supply, HVAC, oil refineries, and chemical processing, among others.

Figure: Horizontal multistage centrifugal pump

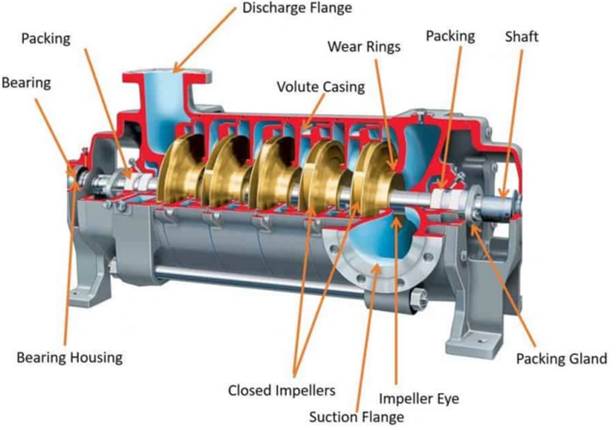

Components of a horizontal multistage centrifugal pump

Electric motor

The electric motor is the component that supplies the power required to pump the liquid. The motor shaft delivers mechanical energy in terms of torque and speed. Horizontal multistage centrifugal pump manufacturers produce the pump to run on a DC or AC motor. The DC motor has the advantage of being solar-powered.

Pump shaft

The pump shaft is the component that receives power from the motor and transmits it into the pump. The shaft is made from metallic solid materials such as stainless steel and carbon steel to ensure it is strong to withstand the torque needed to rotate pump impellers.

Impellers

The impellers are among the main parts of the pump. Impellers serve to impart kinetic energy to the fluid. The pump shaft carries the impellers so that they rotate as it rotates.

Casing

The casing is an external shell of the pump that covers the internal parts of the pump. The casing design varies from pump to pump since there are various horizontal multistage centrifugal pumps. The casing also helps to seal off the pump interior to the atmosphere and prevent fluid leakage and pressure drop.

Bearings

Bearings support the pump shaft to enhance rotation, free from friction. They are of different sizes depending on the pump capacity.

Suction valve and pipe

The suction valve controls fluid flow from the storage tank into the pump. The valve is opened before starting the pump; otherwise, no fluid will flow. The suction pipe conveys the liquid from the storage into the pump.

Discharge valve and pipe

The discharge valve regulates the amount of liquid that leaves the pump. It also prevents fluid from the pipeline from returning to the pump when it is turned off. The discharge pipe connects the pump to the pipe network to allow fluid flow to the required location.

Figure: Components of a horizontal multistage centrifugal pump

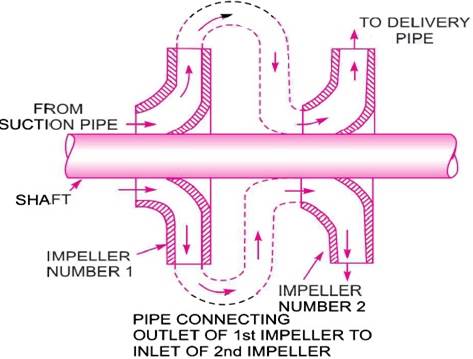

How does a horizontal multistage centrifugal pump work?

The pump operates by using one impeller to feed the next impeller. The liquid enters the pump from the suction end and flows through each impeller until it exits through the discharge end. The pump works by spinning the impellers at sheer speed about the shaft. The rotary power on the impeller comes from the motor shaft via the pump shaft. The high speed of the impeller creates a vacuum in the pump. The vacuum is a state of low pressure relative to the atmospheric pressure on the fluid storage tank. Due to the pressure difference, fluid moves from the storage tank into the pump. The liquid enters the pump and meets the impellers spinning at a very high speed. As such, the fluid absorbs kinetic energy from the impeller, and thus its velocity increases. The liquid then proceeds to the next impeller along the pump casing.

Horizontal multistage centrifugal pump manufacturers design the casing such that it allows the fluid velocity to reduce while increasing fluid pressure energy. The reduction in speed and increase in pressure continues as the fluid progresses along the pump. As such, the fluid leaves the pump at the final stage with more pressure energy than at the first stage.

Figure: Working of a horizontal multistage centrifugal pump

Types of horizontal multistage centrifugal pump

Magnetic drive horizontal multistage centrifugal pump

This pump uses magnets to connect the motor to the pump. The use of magnetic coupling in this pump helps to eliminate the use of mechanical seals. Mechanical seals have the disadvantage of wearing out frequently, which may cause pump leakage. Magnetic technology employs two magnets; the outer and inner magnet. The external magnet is attached to the motor shaft, while the internal magnet is attached to the pump shaft. As such, when the motor shaft rotates, the outer magnet rotates. Due to the magnetic field pattern, the inner magnet also rotates. Rotation of the internal magnet forces the pump shaft to turn at the same speed as the motor shaft. Pump shaft rotation causes impellers to spin, creating a vacuum that draws liquid into the pump.

Horizontal multistage centrifugal pump manufacturers recommend the use of this pump in applications that have corrosive and hazardous fluids. Using this pump in such areas reduces the possibility of legal action due to environmental damage emanating from the leakage of such fluids. Also, this pump can operate for several years without replacing the magnet. This technology makes the pump expensive to acquire but very economical.

Figure: Magnetic drive horizontal multistage centrifugal pump.

Double suction horizontal multistage centrifugal pump

This is a pump designed with two suction entries. Horizontal multistage centrifugal pump manufacturers create the pump to distribute the total fluid flow rate on the impellers. The impellers in this pump are arranged back to back on the pump shaft. This design helps to balance the axial thrust on the impellers. This design also prevents the impellers from damage due to the significant flow rate entering the pump. As such, the pump serves for a long duration without the need to replace the impellers.

Teflon-lined horizontal multistage centrifugal pump

This pump is designed with a Teflon lining in its interior. The lining protects the pump against corrosive products like acids that erode and corrode the metallic impellers, casing, shaft, and packing. The lining enhances service life and reduces frequent repairs and maintenance. This pump is suitable for chemical processing, sewage systems, and salty water. However, the use of this pump is limited to low-temperature applications since high temperatures would destroy the lining.

Self-priming horizontal multistage centrifugal pump

This is a pump designed in a way to prime itself, unlike other pumps that need to be primed manually. The rotation of the impellers creates a vacuum at the impeller’s eye, drawing air into the pump from the suction pipe. Simultaneously, a cylindrical ring of fluid is created in the pump casing. This creates a gas-tight seal that stops air from moving from the discharge end to the suction side. Bubbles of air are trapped in the fluid within the impeller’s vanes and then transferred to the exit port. At the exit port, the air is removed, and the liquid returns via gravity to the pump reservoir. The liquid rises the suction pipe gradually as it is moved out. The process continues until the fluid replaces all the air in the pump and in the suction pipe. Once all the air in the suction line and the pump is removed, the normal fluid pumping starts. Horizontal multistage centrifugal pump manufacturers design the pump such that when the pump is shut off, some fluid is stored in the priming chamber for priming use when the pump is started again.

Applications of horizontal multistage centrifugal pump

- These pumps are used in steam power plants to supply water and steam for power generation.

- They are used in the domestic and municipal water supply.

- They are used in irrigation farms.

- Horizontal multistage centrifugal pumps are used in the oil refinery.

- They are used in firefighting applications.

- They are used in dewatering applications.

- Horizontal multistage centrifugal pumps are used in heating, ventilation, and air conditioning systems.

- They are used in desalination and water treatment.

- They are used as pipeline booster pumps.

- They are used in chemical processing and transportation.

- They are used in the food and beverage industries.

Advantages of horizontal multistage centrifugal pumps

- These pumps are highly versatile in applications.

- They are in a wide range of sizes.

- They are capable of high flow rates like 3000 m3/h

- They can withstand high fluid pressure and temperature, which are common in desalination and steam power plants.

- They are the most common type of pump, making their spare parts available in the market.

- They are easy to install, clean, and repair as they are easily accessible, unlike the vertical pump types.

- They are resistant to corrosion and abrasion wear.

- They produce a large amount of pressure energy.

Disadvantages of horizontal multistage horizontal pumps

- They are more expensive compared to single-stage pumps.

- Most of these pumps use mechanical seals that wear frequently and then need replacement.

- They occupy large floor space.

Troubleshooting horizontal multistage pumps

The pump does not prime

- Leakage through the suction pipe. Repair the suction pipe.

- The discharge valve is open or leaking. Check the discharge valve and repair it if leaking. If it is open, close it.

- The pump packing is worn-out. Replace the packing.

- Too high suction lift. Lower suction lift if possible.

Zero fluid flow

- The suction lift is too high. Lower the pump or raise the liquid in the suction tank.

- Air in the suction pipe or the pump. Ensure the pump is adequately primed to remove air from the pump and the suction line.

- Wrong direction of motor rotation. Change the motor direction of rotation to match the rotation arrow on the pump casing or as recommended by the horizontal multistage horizontal pump manufacturer.

- Clogged impellers, strainer or suction valve. Check the filter, impellers, or suction valve and remove any blocking materials.

- The discharge valve closed. Open the discharge valve.

- Closed suction. Open the suction valve.

Bearings overheating

- Excess torque on bearing cover. Loosen the cover.

- Poor coupling alignment. Realign the coupling properly.

- Fluid flow through the pump is low than the set flow rate. Increase flow rate as recommended by the horizontal multistage centrifugal pump manufacturer.

- Insufficient lubricating oil. Clean the bearings and apply enough lubricant.

Pump producing high vibrations

- Blocked impeller. Clean the impeller.

- Worn-out impellers. Replace the worn-out impeller.

- Improperly aligned coupling. Align the coupling properly.

- Oblique shaft. Replace the shaft.

- Worn out bearings. Replace the bearings.

- Discharge or suction not firmly supported. Improve pump support.

Pump reduced performance

- Leakage through the suction line. Repair the suction line.

- Worn-out packing. Replace packing.

- The pump speed is too low. Improve speed to the range recommended by the horizontal multistage centrifugal pump manufacturer.

Summary

A horizontal multistage centrifugal pump is a pump in which the motor and pump are installed in a horizontal plane. This pump uses more than one impeller. The impellers are arranged in series from left to right. Each impeller serves as a fluid chamber or stage. Each stage consists of a diffuser, impeller, and return guide vane housed in one stage casing. This pump produces a lot of pressure energy relative to the number of impellers used. At each stage, the fluid pressure increases until it leaves the pump via the discharge port. The pump operates by rotating the impellers at speed to create a vacuum that draws the liquid from the storage tank into the pump.

Horizontal multistage centrifugal pump manufacturers design various types of this pump, such as magnetic drive pumps, self-priming pumps, Teflon lined pumps, and double suction pumps. The advantages of this pump are that it is easy to install and repair, is very versatile, resistant to corrosion, and can produce high-pressure energy. The applications of this pump include water supply and treatment, chemical processing, firefighting, HVAC systems, foods and beverages, and oil refinery, among others.