submersible Pump for Dirty Water

What is a submersible pump for dirty water?

A submersible pump for dirty water is a pump designed to be completely immersed in contaminated water during operation. The pump primarily applies in pumping dirty water that is not chemically aggressive towards the pump’s material. A submersible pump for dirty water can handle water containing sand, soil, and residuals. Its heavy-duty models can even deal with coarser materials such as large solid particles. The impeller at the bottom of a submersible pump for dirty water processes solid particles by cutting them up so that they can be easily drained. Submersible pumps for dirty water perfectly cater to a host of applications, including clearing dirty water, discharging domestic waste water, emptying tanks, and emptying collection traps containing suspended solids with a maximum diameter of 20 mm. The submersible dirty water pump manufacturers design the pump for a maximum immersion depth of 5 meters, pressure head of 8.7 meters, and flow rate of up to1 0.7 cubic meters per hour.

Figure: A submersible pump for dirty water

Components of a submersible pump for dirty water?

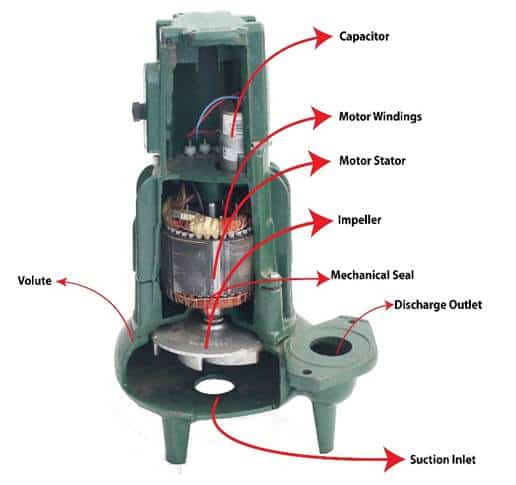

Pump casing

The casing is the outside shell of the pump. It houses the impeller, shaft, bearing housing, and other internal components of the pump. The casing seals off the pump inside from the atmosphere, preventing leakage and retaining pressure. During operation, the casing directs the flow into the pump through the suction pipe and out of the pump through the delivery pipe. The pump casings differentiate themselves mainly in terms of design and are either radially split or axially split. The pump casing can be made of cast or wrought iron, chromium, or duplex steel. Some pumps may contain a pump casing made of plastic.

Electric motor

The electric motor is the source of mechanical power in a submersible pump for dirty water. The motor runs the pump to move fluid to the required destination. In a submersible dirty water pump, the motor is hermetically sealed and connected to the pump head via a coupling to transmit torque. The motor can be DC or AC types depending on the nature of the current supply. Submersible dirty water pump manufacturers mostly design the pump motor with a built-in protection device that switches off the motor in case any challenge arises.

Shaft

The shaft is a rotary mechanical component carrying the pump impeller and riding on the bearing. The pump shaft links the rotor assembly to the prime mover through a coupling. When the motor runs, the pump shaft rotates the pump impeller to displace the fluid. Submersible dirty water pump manufacturers create the pump shaft from materials that overcome vibrations and heavy loads during pump operation. Such materials include stainless steel and carbon steel, alloy steel, etc.

Impeller

The impeller or the rotor is made of a series of backward-curved vanes. It is usually keyed to the pump shaft and the whole assembly is placed in the pump casing. Its main function is to displace fluid through the pump by increasing the kinetic energy and pressure of the fluid. The pump impeller comes in different designs, including axial, radial, single and double suction.

Bearings

The main purpose of the bearings is to support the shaft or the impeller and to align them correctly with the fixed ends under the action of radial and axial forces. They also help to reduce the friction between the rotating shaft and the stator and contain the relative motion of the rotor assembly.

Delivery Pipe

The main purpose of the suction pipe is to lift fluid to the required area. The delivery pipe has two ends with one end connecting to the outlet of the pump and the other delivering the water to a required destination.

Valves

The submersible pump for dirty water also contains different types of valves such as relief valves, drain valves, and ball valves that help with the pump operation. The relief valve protects the pump from excessive pressure which could damage the plumbing system. The drain valve helps to drain the tank and water system when replacing the pressure tank. The ball valve is found on the discharge side of the pump and it isolates the plumbing system from the water well pressure system.

Pump cable

A Submersible pump cable is used to supply electrical power to the submersible pump for dirty water. Submersible pumps for dirty water can have either two or 3 power cables depending on the motor design.

Figure: Components of a submersible pump for dirty water

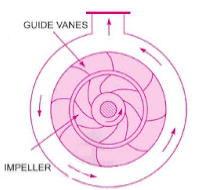

How does a submersible pump for dirty water work?

A submersible pump for dirty water pushes water to the surface by converting an impeller’s rotary energy into fluid’s kinetic energy and then pressure energy. When the motor starts, the pump shafts rotate the pump impeller at the motor’s speed. The centrifugal effect of the pump impeller creates a vacuum inside the pump and water is drawn into the pump body through the suction grid fitted to the bottom. When the water strikes the impeller blades, the centrifugal force moves the water radially and axially outwards until it enters the volute chamber at a very high velocity. In the volute chamber, the high velocity of the water is converted into a high-pressure head, allowing the water to discharge from the pump to the required destination through the delivery pipes or hoses attached to the delivery port. The pump must be fully immersed in the water because it also relies on the water for cooling. Therefore, running a submersible pump for dirty water under dry conditions can cause pump damage.

Types of submersible pumps for dirty water

Single-stage submersible pumps for dirty water

The single-stage submersible pumps for dirty water consist of one impeller rotating on a shaft in a pump chamber. It is the simplest design of the submersible pumps for dirty water. Single-stage submersible pumps for dirty water are mostly used for home and light industrial pumping, including aquarium filters, drainage, domestic wastewater, etc.

Figure: single-stage submersible pump for dirty water.

Multiple-stage submersible pumps for dirty water

Multiple-stage submersible pumps for dirty water consist of two or more impellers housed in different pump chambers that are connected in series. The pumped fluid is drawn into the first chamber (stage) at suction pressure and exits from the last chamber at very high pressure. Multiple-stage submersible pumps for dirty water mainly apply in underground uses, such as water wells, and deep-well drilling.

Figure: Multiple-stage submersible pump for dirty water.

Applications of submersible pumps for dirty water

Submersible pumps for dirty water are excellent for a wide range of domestic and industrial applications, including deep good drilling, drainage, water treatment, construction, and irrigation systems. They have the following uses.

- Submersible pumps for dirty water are used for cleaning dirty water

- They are also used for emptying tanks

- They are also used to pump excess water from work sites or flooded basements in construction sites.

- They also apply in discharging domestic wastewater

- Submersible pumps for dirty water also apply in emptying collection traps containing suspended solids.

- They are used to drain infiltration water, cesspools, or reservoirs.

- They are also used for draining clean, dirty, or muddy swimming pools.

Advantages of a submersible pump for dirty water

- A submersible pump for dirty water is simple in design and easy to control

- The pump does not need to be primed because it is submerged in water.

- A submersible pump for dirty water highly reliable in drainage operations

- A submersible pump for dirty water can handle water containing suspended solid particles

- The pump’s design is robust, allowing easier pump installation

- A submersible pump for dirty water is free of cavitation because it does not experience a spike in water pressure during pumping operation.

- A submersible pump for dirty water has minimal maintenance and repair requirements

- It is perfect for large quantities of water and a wide range of flow rates

- A submersible pump for dirty water is very quiet in operation since it is submersible

Disadvantages of a submersible pump for dirty water

- The submersible pump for dirty water must always operate in submerged conditions to prevent overheating

- No single pump design can fit all uses. Single-stage types of submersible pumps for dirty water are mostly suitable for home and light industrial pumping. Multiple stages counterparts are primarily used for underground operations such as borehole drilling, well water pumping, etc.

- The pump seals may corrode over an extended duration of pump operation, causing pump leakage.

- The motor may be difficult to access for repairs due to mechanical seals

Troubleshooting a submersible pump for dirty water

The motor does not run

- The fuse is blown out. Inspect and replace the fuse if necessary

- No power supply to control the Panel. Ensure that the power cable connections meet the submersible dirty water pump manufacturers’ guidelines. Check the main input panel

- The pump cables are broken. Inspect and change the control cables if necessary

The pump gives zero discharge

- The discharge pipe is blocked. Inspect and clear any blockage in the discharge pipe

- The pump’s discharge head is insufficient. Check the system design values from the submersible dirty water pump manufacturer’s manual.

- The impeller is seized. Inspect the impeller for blockage and clean it.

- The pump is operating in reverse. Reverse the motor polarities. Ensure that the motor rotates in the direction indicated by the arrow on the pump’s nameplate.

The pump has low capacity

- The pump impeller is severely worn-out. Inspect and replace the pump impeller if required.

- The discharge pipe is blocked. Inspect and clear the discharge pipes.

- The pump is operating in reverse. Reverse pump polarities

- Either the pump casing or the impeller is partially clogged. Dismantle and clean the pump interiors.

The pump is showing excessive vibration and noise

- Several pump components are unbalanced. Inspect and rebalance pump components

- The pump shaft and the prime mover are significantly misaligned. Inspect and realign the shafts.

- The pump is working in cavitation. Ensure that the inlet valves are fully open. Also, check that the pump is correct according to the specifications of the submersible pump for dirty water manufacturers.

- The pump bearings or impeller are worn-out. Replace bearings or impeller if it is necessary

Thermal trip

- The pump head is very low. Adjust the pump head or install a control valve to detect and maintain back pressure to the required level.

- The stop level is set too low. Ensure that the stop switch level value is correct or set to the level required by the submersible dirty water pump manufacturers.

There is suction or discharge recirculation

- The pump’s flow rate is too low. Ensure that the pump’s flow rate is within the range recommended by the submersible dirty water pump manufacturer.

The leakage detector is activated

- The detector cable is compromised by wear, damage, or contact with oils. Inspect the cable condition and replace it if necessary.

Summary

A submersible pump for dirty water is a pump that can be completely immersed in the pumped fluid during operation. A submersible pump for dirty water is mainly used in pumping dirty water. It must always be submerged in the water because it relies on the pumped medium for cooling. A submersible pump for dirty water is suitable for dealing with water containing solid particles because the pump impeller cuts them up for easier draining. The submersible dirty water pump has single-stage and multiple-stage types. It can cater to a wide range of applications including discharging domestic wastewater, emptying tanks, deep-well drilling, drainage, water treatment, construction, etc. Submersible dirty water pump manufacturers design the pump with compact construction, allowing easy pump installation and control. The pump is quiet, energy efficient, and highly reliable in operation.