Engineering Plastics Magnetic Drive Pump

What is an engineering plastics magnetic drive pump?

This is a magnetic drive pump that is made of engineering plastic material. Engineering plastic material has better mechanical and thermal properties compared to commonly used plastics such as PVC and polystyrene. Purchasing engineering plastics magnetic drive pumps gives you the advantage of high heat resistance relative to one made of standard plastic material. The pump can withstand high temperatures of up to around 150 oC. These pumps are designed without seals but rather with inner and outer magnets. The magnets connect the pump impeller which is used to move fluid through the pump.

The seal less property is created by having the inner and drive magnets separated by the rear casing. By employing this technology, the pump is free from any leakage. Leakage-free property is very important especially when it is used to transport dangerous and costly fluids, therefore, preventing losses through environmental damage. Also, this pump has the advantage of less maintenance cost since it has no seals. The possibility of this pump failing is low since it has only two moving parts (impeller and shaft).

Figure: Engineering plastics magnetic drive pump

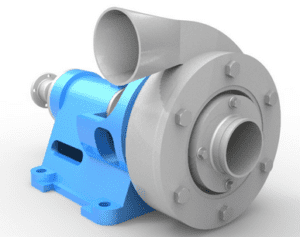

Components of an engineering plastics magnetic drive pump

Prime mover

The prime mover is the component that provides the energy needed to operate the pump. The prime mover an electric motor.

Pump shaft

The pump shaft is the component on which the impeller is mounted on. Engineering plastics magnetic drive pump manufacturers make the shaft from strong metallic materials such as carbon steel and stainless steel to ensure it can withstand the torque needed to rotate the pump impeller. The shaft is supported on bearings to ensure smooth rotation.

Impeller

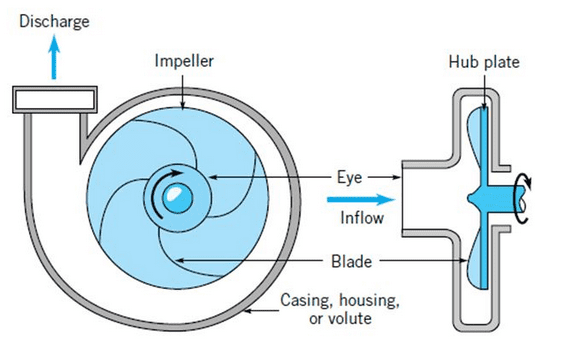

The impeller consists of backward-curved vanes. It is mounted on the shaft connected to the motor. The work of the impeller is to impart kinetic energy to the fluid by creating a vacuum in the pump through its high speed rotation.

Pump casing

The casing is a component that houses the impeller. Engineering plastics magnetic drive pump manufacturers design the casing such that the fluid’s kinetic energy exits through the outlet as that energy is converted into pressure energy before leaving the casing and delivered to the delivery pipe. By transforming the fluid velocity created by the impeller results to a stable fluid flow.

Magnets

The pump is designed with outer and inner magnets. The outer magnet helps to rotate the inner magnet on the impeller so that the impeller can rotate and thus start pumping the liquid.

Bearings

Bearings are components used to support the pump shaft to ensure smooth rotation as well as reduce friction.

Delivery pipe

This is a pipe that is connected to the pump outlet port and it is used to deliver fluid to the pipeline and the required destination.

Suction pipe

This is the pipe that is dipped into the sump to convey fluid into the pump. One end of the pipe is connected to the pump and the other end is dipped into the fluid source (sump).

Figure: Components of an engineering plastics magnetic drive pump

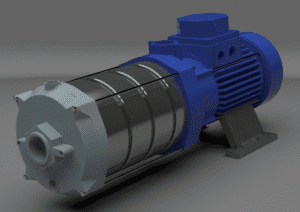

How does an engineering plastics magnetic drive pump work?

Engineering plastics magnetic drive pump manufacturers attach the magnets to the pump drive assembly. The drive magnet is meant to drive the inner pump rotor and it is attached to a shaft that is operated by the motor. When the motor is powered, it rotates its magnet. As such, the magnetic force from the motor magnet causes the impeller magnet to rotate and thus the impeller starts spinning. Due to the impeller rotation, a vacuum is created in the pump which forces fluid into the pump. The liquid is usually thrown off the pump impeller to the exit side. The impeller rotation forces the liquid’s energy to increase thus increasing the pressure energy needed to transport the fluid from one place to another.

Figure: Working of an engineering plastics magnetic drive pump

Types of engineering plastics magnetic drive pumps

Horizontal engineering plastics magnetic drive pump

This is the version of the engineering plastics magnetic drive pump which is designed to transport fluid at very speed with a direct motor drive. This pump is installed in a horizontal orientation. Due to this orientation, it is easy to install, repair, and do maintenance since the parts are easy to access. This pump has low headroom making it a great solution for indoor use where space is limited. Engineering plastics magnetic drive pumps can be safely secured to the prime mover due to close distance reducing the possibility of shaft failure. This magnetic pump also has low noise levels relative to the vertical pump type.

Figure: Horizontal engineering plastics magnetic drive pump.

Vertical engineering plastics magnetic drive pump

This is the pump that is installed in a vertical orientation. Pump manufacturers design the pump such that it can be connected to the motor without a coupling or by use of a long couple using a spacer bracket. This pump is best for use in transporting liquids from deep wells or pits due to its vertical orientation properties. Such pumps are very efficient in applications involving high head and low fluid flow. It is also of small size allowing it to fit in tight vertical spaces. In addition to being able to work in deep wells and pits, this pump is capable of continuous fluid flow. However, vertical engineering plastic magnetic drive pumps have complicated maintenance. These pumps also have high levels of noise relative to the horizontal ones. It occupies a large vertical area of installation.

Figure: Vertical engineering plastics magnetic drive pump.

Single-stage engineering plastics magnetic drive pump

This pump consists of one impeller. The impeller is mounted on the motor shaft and thus it rotates when the motor is turned on. This is one of the simplest engineering plastic magnetic drive pumps. The pump has its internal parts made of engineering plastic materials which ensure it is resistant to corrosion and can withstand temperatures up to around 150 oC. This pump is designed to fit different areas of applications ranging from water, chemicals, and oil products.

Figure: Single stage engineering plastics magnetic drive pump.

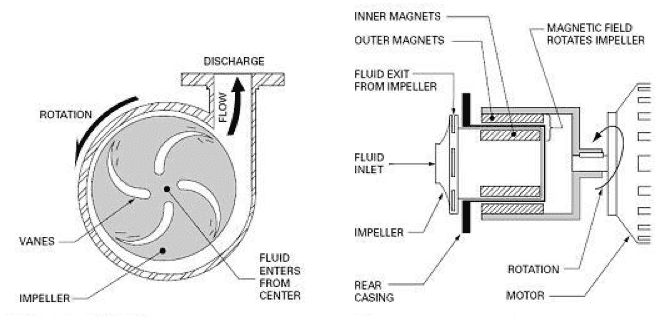

Multistage engineering plastics magnetic drive pump

This version of the engineering plastics magnetic drive pump is designed with multiple stages or fluid chambers. The fluid chambers are connected in series. This allows fluid to enter the pump through the first chamber at the entrance port and leave through the outlet at very high pressure. The fluid gets more pressure energy as it moves from one stage to another. As such, the more chambers the engineering plastics magnetic drive pump has, the higher the discharge pressure. However, the fluid flow range remains constant for a certain rpm. The design of this type of pump can have a vertical or horizontal installation depending on the area of application. This pump is also energy-saving and can work in a wide range of fluid heads. However, it is very important to first consult pump experts on the right pump to ensure you get the best for that application.

Figure: Multistage engineering magnetic drive pump.

Applications of engineering plastics magnetic drive pumps

- These pumps are used in municipal and domestic water supply.

- They are used in chemical manufacturing plants since they are resistant to corrosion.

- Engineering plastics magnetic drive pumps are used in pressure boosting applications.

- They are used in the foods and beverage industries to transport water, juice, and other products.

- They are used in fire protection as well as heating and cooling applications.

- They are used in pharmaceuticals and cosmetics industries to transfer products such as glucose, lactose, and other personal care and drugs of varying viscosity and medium.

- They are used to handle hydrocarbons and chemicals since they are free from leakage hence ensuring no dangers of fire and or environmental damage.

Advantages of engineering plastics magnetic drive pumps

- These pumps are free from fluid leakage thus ensuring no environmental damage or fire accidents.

- They are resistant to corrosion as they are made of engineering plastic materials.

- Engineering plastics magnetic drive pumps are of various sizes to suit applications of any size.

- These pumps are highly resistant to heat relative to pumps coated with commonly used plastics like PVC.

- It has two rotating parts which reduces the chances of wear. This also makes repair and maintenance cheaper relative to other pumps.

- These pumps are lighter in weight relative to their metallic counterparts.

- Engineering plastics magnetic drive pumps are of reliable service.

- These pumps have high energy efficiency relative to other pumps. The high efficiency helps to reduce running costs in terms of energy over a short-term or long-term period of use.

- They are of smooth flow as they can avoid pulsing fluid flow.

- They are versatile as they are applicable in a variety of industries.

Disadvantages of engineering plastics magnetic drive pumps

- These pumps are only suitable for use in clean liquids free from solids. Even small solids can stall them.

- These pumps consume more power relative to other pumps.

- Considering the cost, these pumps are more expensive. However, due to their low maintenance costs, their life service becomes cheaper.

Troubleshooting engineering plastics magnetic drive pumps

Insufficient pressure

- Small impeller diameter. Replace the impeller.

- Incorrect motor rotation. Change the motor rotation.

Low or no discharge

- Leakage through the suction pipe. Check for leakage and repair or replace the suction pipe as necessary.

- The pump is not primed. Prime the pump.

- Very high system head. Use a higher-rated pump.

- The Inlet valve is closed. Open the valve.

- Incorrect motor rotation. Change the direction of motor rotation.

- Very high fluid viscosity. Use the pump at the viscosity recommended by the engineering plastics magnetic pump manufacturer.

- The suction lift is too high. Reduce the suction lift or use a more powerful pump.

- Clogged impeller vanes or suction lines. Open the pump and clean off the clogged impeller or suction line.

Loss of prime

- Leakage through the suction line. Repair or replace the suction line.

- Air in the fluid. Remove air contained in the fluid.

- Foreign materials in the pump. Remove the foreign materials.

Excess power consumption

- Excess fluid viscosity. Use the pump at the recommended fluid viscosity.

Vibrations and noise

- Foreign materials in the impeller. Open the pump and remove such materials.

- The motor and pipe are loosely connected. Ensure the connections are tight as recommended by the engineering plastics magnetic drive pump manufacturer.

Summary

Engineering plastics magnetic drive pump is made from engineering plastic material. Such materials are highly resistant to corrosion and have higher heat resistance. Such materials make the pump suitable for use in applications that have hot and corrosive liquids. This pump can withstand temperatures up to around 150 oC. This type of pump operates by use of magnets that are the drive magnet and the inner magnet. The inner and the drive magnets are separated by casing or housing creating a containment free from seals. Such property helps the pump to operate without any leakage which may cause losses and or environmental damage.

Engineering plastics magnetic drive pump manufacturers produce various types of these pumps which include horizontal pumps, vertical pumps, single-stage pumps, and multistage pumps among others. The applications of these pumps include oil supply, water supply, chemical industries, and fire protection among others. The advantages of using engineering plastics magnetic drive pumps are simple design, easy repair, and maintenance, free from leakage, compact design, reliability, high efficiency, reduced downtime, and versatility. However, this pump is recommended for use in applications that involve clean liquids free from solids.