Vertical Sewage Pump

What is a vertical sewage pump?

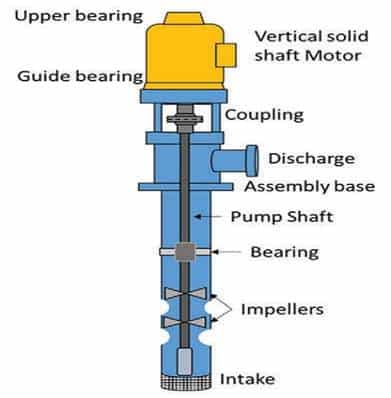

A vertical sewage pump consists of a vertically oriented shaft with a close coupling between the driver and the pump head. Based on the principle of operation, the vertical sewage pump is a centrifugal pump because it uses a rotating impeller to displace the pumped liquid through the pump. Sometimes the vertical sewage pump manufacturers design it with a long coupling using a spacer bracket that acts as a support for the motor. The long-coupled design allows easier pump maintenance because the motor doesn’t have to be removed during repair. The vertical sewage pump is recommended for applications where the floor space is limited and also for buildings in low-lying areas where sewage cannot flow by gravity to the existing sewerage infrastructure. Vertical sewage pumps are widely preferred because of their excellent performance parameters, such as high flow rates (up to 2200 cubic meters per hour) and a high-pressure head of about 15 meters.

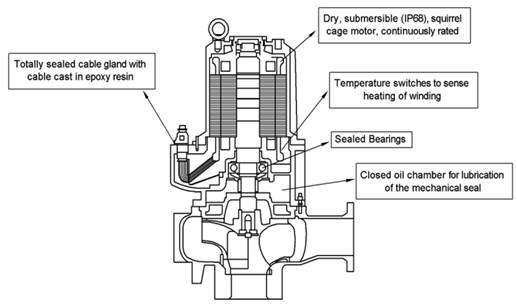

Figure: Showing the configuration of a vertical sewage pump

A vertical sewage pump is used to transport liquid with solid particles and long fibers litter. Vertical sewage pumps are widely used for sewage discharge from municipal works, sewage treatment plants, and mining and power plants. They come with an adjustable suction inlet and discharge outlet, which allow the customers to adjust the flow to meet various application requirements. Vertical sewage pumps are leakage-free, highly reliable, and do not require any external cooling. They are also anti-winding and anti-blocking.

Components of a vertical sewage pump

Electric Motor

The purpose of the electric motor is to provide the mechanical power to rotate the pump impeller which displaces the pumped fluid through the pump system. The electrical motor converts the electrical supply energy into mechanical energy for running the pump. The supply power to the motor can be either direct current (DC) or alternating current (AC). Therefore, electric motors are classified as AC motors, which work with alternating current, or DC motors, which operate with a direct current.

Bearings

The bearings support the pump shaft and the rotor assembly at large, ensuring perfect alignment with the pump body. The bearings carry the fully rotary load of the shaft during operation and reduce friction between the rotating shaft and the stator for smooth operation.

Mechanical seals

The main purpose of mechanical seals is to prevent fluid under pressure from leaking out of the pump. Mechanical seals also prevent the vertical sewage pump from sucking in the air under vacuum conditions.

Pump body (casing)

The pump body or casing is the outer covering that contains and protects most of the vertical sewage pump’s internals, including the shaft, bearings, impeller, shaft sleeve, etc. The pump housing is usually sealed to retain pressure and prevent the leakage of pumped fluid under pressure. The pump housing also carries the inlet and outlet ports of the pump. The fluid enters through the suction port at suction pressure and exits via the discharge port at elevated pressure.

Shaft

The is a rotary mechanical component supported by the bearing and carrying the impeller in a vertical sewage pump. It is part of the rotor assembly. Its main purpose is to transmit mechanical torque from the motor to the impeller, displacing the fluid in the pump. The pump shaft connects the rotor assembly (shaft, bearing, impeller, shaft sleeve, etc.) to the electric motor via a coupling. In a vertical sewage pump, the shaft can be either close-coupled or long-coupled to the pump impeller depending on the application of the pump.

Impeller

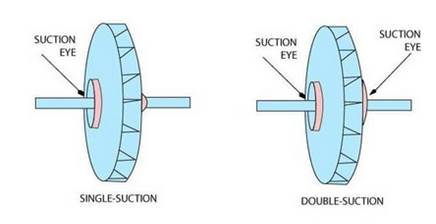

The impeller consists of backward-curved vanes. The main function of the impeller is to displace the pumped fluid through the pump when it rotates. The impeller can have either axial or radial flow construction. In an axial flow impeller, the liquid flows axially to the shaft, while the fluid flows radially to the shaft in a radial flow impeller. Vertical sewage pumps employ radial flow impellers which may have either open or closed impeller designs. Open impellers have only one shroud with the vanes exposed on one side. They are mainly used in single-stage, single-suction centrifugal pumps. A closed impeller has shrouds on either side and the impeller vanes are sitting between the shrouds. Closed impellers have two main configurations: single or double suction. Vertical sewage pump manufacturers prefer a radial flow impeller with an open design because it can efficiently handle large amounts of suspended bodies and high-viscosity fluids.

Figure: Showing closed impellers: single and double suction configurations

Pump Inlet and outlet ports

The pump inlet port connects to the suction line which dips into the sump while the outlet connects to the discharge hose, delivering the pumped liquid to the required location. The pumping medium enters the pump through the inlet section and discharges via the outlet section.

Figure: Showing closed impellers: single and double suction configurations

How does a vertical sewage pump work?

When the electric induction motor is run, it rotates the impeller through the pump shaft and coupling. The rotation of the impeller creates a vacuum inside the pump casing. Consequently, the higher atmospheric pressure outside the pump forces the liquid into the vertical sewage pump’s casing through the pump inlet. When the liquid strikes the blades of the impeller, it is rotated radially and axially outwards, due to the centrifugal force acting on the blades, until it passes through all of the impeller components. The impeller blades impart kinetic energy to the liquid and throw it into the diffuser chamber at a very high speed. In the diffusing chamber, the speed of the water is gradually decreased leading to the conversion of the high-velocity energy into a high-pressure head. The diffuser then guides the water into the delivery pipe through which it moves to the required location.

Types of vertical sewage pump

Submersible vertical sewage pump

A submersible vertical sewage pump is completely immersed in the pumped liquid during operation. Submersible vertical sewage pump contains a seal of oil around the motor which helps in cooling.

Figure: Showing the arrangement of internals in a submersible vertical sewage pump.

Non-submersible vertical sewage pump

This kind of vertical sewage pump operates outside the pumped fluid. Only the suction inlet is placed inside the sump while the rest of the pump remains outside.

Figure: Showing a non-submersible vertical sewage pump.

Vertical inline sewage pump

The vertical inline sewage pump is installed along the pipeline like a valve. It contains suction and discharge ports that lie in a straight line in the piping system.

Figure: Showing the configuration of a vertical inline sewage pump.

Applications of a vertical sewage pump

The vertical sewage pumps excellently cater to a wide scope of industries, including municipal works, sewage treatment plants, power generation plants, mining, and pumping stations. Typical uses include:

- Vertical sewage pumps are used for sewage transfer in treatment plants

- They are used for discharging sewage in municipal work, pumping station

- They are used to pump sewage to sewerage infrastructure in low-lying regions where sewage cannot flow by gravity.

- They are also used for pumping industrial wastewater

- Vertical sewage pumps are also used in private homes and commercial buildings that are not connected to municipal sewers due to the nature of the terrain.

- Vertical sewage pumps are also used in the washing of industrial mines

- They are is used in chemical industries to transport viscous fluids.

- They are used for transferring any liquid containing suspended particles and fibers.

Advantages of vertical sewage pump

- Vertical sewage pumps are space-saving. The motor is installed above the pump casing thus occupying less floor space.

- Vertical sewage pumps are easier to install and operate because they have a simplified construction. The close-coupled design eliminates the need for shaft alignment or additional bearing assembly.

- vertical sewage pumps provide high reliability and efficiency.

- Vertical sewage pumps require minimal routine maintenance because they have few parts that experience wear.

- They are perfect for extreme temperature and pressure scenarios because vertical sewage pump manufacturers design them to withstand thermal expansion.

- Vertical sewage pumps are quiet in operation since the vertical shaft is naturally balanced and gravitation forces do not oppose the shaft’s rotation direction.

Disadvantages of a vertical sewage pump

- The vertical sewage pump requires vertical clearance for installation and maintenance.

- Due to the vertical configuration, the weight of the pump falls below the volute, which may lead to a large stress concentration.

- A vertical sewage pump with a close couple design can be difficult to maintain as the motor and pump head must be disconnected to service the pump internals. This may become a major challenge, especially for pumps using large motors.

- Vertical sewage pumps do not have a mechanism to stop the impeller and may run backward especially when the pump is stopped without first closing the discharge line.

- The vertical sewage pump’s capacity can drastically reduce if there is air leakage.

Troubleshooting vertical sewage pump

The motor doesn’t run or is overheating

- The motor is poorly installed. Ensure the pump is installed following the vertical sewage pump manufacturers’ guidelines.

- There is a tripped circuit breaker or a blown fuse. Inspect the pump for a blown fuse and replace it. insect and reset the circuit breaker if it is needed.

- The motor is defective. Inspect and replace the motor if it is necessary

The pump gives out little or no discharge after startup

- The vertical pump operation is reversed. Ensure that the direction of the motor rotation matches the direction indicated by the vertical sewage pump manufacturer using the arrow in the nameplate. Reverse the motor polarities

- The impeller or check valve is clogged. Inspect and clear any blockage in the valve or impeller.

- The monomeric head is insufficient due to high friction losses that exceed the pump design. Increase the pump power. Make sure the pipes used in the piping network meet the diameter recommended by the vertical sewage pump manufacturer.

- There is air in the pump or suction pipework. Ensure that the pump or pipework is filled with water to drive out the air.

The pump’s driver is overloaded

- The Pump speed is too high. Reduce the pump speed.

- Faulty pump motor. Inspect the motor for defects and repair or replace it if necessary.

- Some pump parts are prone to extreme mechanical friction. Inspect the pump assembly for any obstruction or deflection and correct it.

The pump is experiencing excessive vibration or noise

- Some pump components are unbalanced. Inspect and rebalance parts if necessary.

- The pump impeller is partially clogged. Inspect and clean the impeller.

- The impeller is severely worn out or defective. Inspect and replace the impeller.

- Some pump components are loosely held within the pump body. Tighten any loose parts to the torque level recommended by the vertical sewage pump manufacturer.

- The pump is working in cavitation. Check that the suction line valves are fully open.

- There is air in the liquid. Ensure that the suction pipe is completely submerged to prevent the formation of vortexes on the surface of the liquid.

Summary

A vertical sewage pump is a type of centrifugal pump comprising a vertically oriented shaft with a close coupling between the driver and the pump head. Vertical sewage pump manufacturers may also install the pump with a long coupling that uses a spacer bracket, acting as motor support. The long coupling design facilities easier pump maintenance. Vertical sewage pumps are used for transferring liquid containing solid particles and long fibers litter. A vertical sewage pump can be submersible or non-submersible. Vertical sewage pumps are widely used for sewage discharge from municipal work, sewage treatment plants, and mining and power plants. Vertical sewage pumps are widely preferred for their excellent performance parameters and anti-winding and anti-blocking abilities. Vertical sewage pumps have high-performance efficiency and reliability and are space-saving and easier to install and operate.