Horizontal Water Transfer Pump

What is a horizontal water transfer pump?

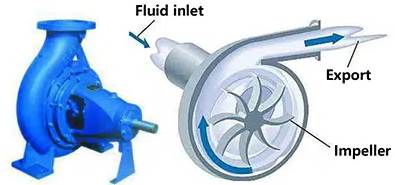

A horizontal water transfer pump transports water from one point to another. The pump is designed to be installed in a horizontal orientation. Due to the horizontal installation, this pump takes up larger floor space, and thus installation space should be considered when purchasing the pump. The pump operates by rotating internal impellers that force fluid flow from a storage tank into the pump and then to the piping system. Horizontal water transfer pump manufacturers produce pumps of different sizes to help suit all areas of water transfer. This means that if you require small sized water pump or large sized pump, you will get it. The large pumps can produce significant fluid flow rates, such as 2000 m3/h. These pumps are available in various materials such as stainless steel and carbon steel, with some having plastic coating to prevent corrosion in case of salty water.

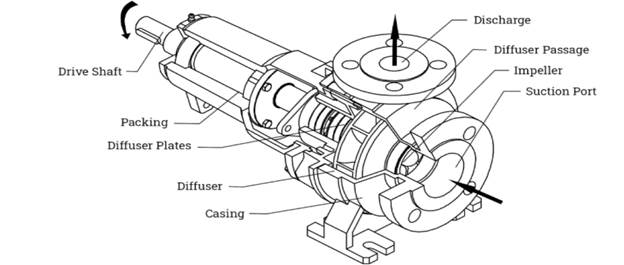

Figure: Horizontal water transfer pump

Components of a horizontal water transfer pump

Electric motor

The electric motor is the component used to power the pump. The motor is connected to electricity using electrical cables. These cables transmit power from the mains supply to the electric motor. The motor works by converting electrical energy into mechanical energy. The mechanical energy from the motor is transmitted via the motor shaft. When the pump is started, the motor shaft rotates at a very high speed. The motor shaft and pump shaft are connected together using a coupling or shaft key.

Pump shaft

The pump shaft is used to connect the pump to the electric motor. The pump shaft transmits power from the electric motor to the pump. Horizontal water transfer pump manufacturers produce this shaft from high-strength metallic materials like steel to ensure it is strong enough to transmit the torque needed on the pump.

Pump impellers

Impellers are rotating discs that have curved vanes. They transfer mechanical energy from the shaft to the water being pumped. They increase the fluid velocity as water moves radially out of the impeller’s eye. Horizontal water transfer pump manufacturers design the impellers as either channel or vortex impellers.

Casing

The casing is an external component used to prevent water leakage and maintain pressure by providing a seal between the inside of the pump and the atmosphere. The casing can be single-volute, double-volute, or vanned diffuser casing. Among the three, the single volute is the most common and is used mainly in low and medium flow rates in single-stage pumps. The double volute is used chiefly in large single-stage pumps. The vanned diffuser casing is used mainly in multistage pumps for effective flow rates and high head. The work of the casing is to increase water pressure while reducing fluid velocity as the water moves outwards of the impellers to the discharge port.

Discharge valve and pipe

The discharge valve regulates the amount of water leaving the pump. It connects the pump to the pipe network. The pipe network conveys water from the pump to the required destination.

Suction valve and pipe

Horizontal water transfer pump manufacturers design the pumps with a strainer that helps to filter the water entering the pump and thus remove solid particles that may block the pump or the pipe network. The suction pipe connects the pump to the water tank or water source. The suction valve controls the amount of water entering the pump from the tank.

Figure: Components of a horizontal water transfer pump

How does a horizontal water transfer pump work?

A horizontal water transfer pump operates by using pressure difference. The pump starts working when there is an electrical power supply on the motor. With the power available, the motor shaft rotates. Since the motor shaft is coupled to the pump shaft, the pump shaft starts rotating at the same speed. Due to the pump shaft rotation, the pump impellers rotates as they are mounted on the same shaft. Impeller rotation at high speed creates a vacuum in the pump. As such, the atmospheric pressure on the tank’s water surface pushes the water into the pump. On entering the pump, the water meets the impeller at its center. Due to the impeller rotation, the water moves radially outwards between the impeller and pump casing. The impeller rotation adds kinetic energy to the water entering the pump. As the water moves along the casing, the kinetic energy is reduced, but its pressure energy is increased relative to the casing design. As such, the water gains enough pressure energy to flow to the required destination.

Figure: Working of the horizontal water transfer pump.

Self-priming horizontal water transfer pump

A self-priming pump is one which does not need to be primed before it starts water transfer. Horizontal water transfer pump manufacturers design the pump to vent off the air before it starts to pump the water. The pump creates a partial vacuum, which helps to remove air in the water. The air is forced to rise and leave the pump while the water goes back to the pump via gravity. The water mixes with any other air remaining in the suction line. The exact process repeats until all the air is vented off the pump. Once all the air is removed from the pump, atmospheric pressure forces the water on the storage tank into the pump impellers, and the pumping process starts. Horizontal water transfer pump manufacturers design the pump such that some water remains in the pump when the pump is turned off. This water is meant to prime the pump when it is started again. This type of pump is highly reliable and does not need additional valves to operate. However, this pump uses separation chamber which reduces efficiency.

Figure: Self-priming horizontal water transfer pump.

Single-stage horizontal water transfer pump

This is the most common type of horizontal water transfer pump. This pump uses one impeller to create pressure energy needed to transfer water to the needed destination. Its main challenge is low-pressure energy compared to the multistage pump type. The single-stage pump is economical and easy to clean and repair. It is also cheaper compared to the multistage pump. As such, manufacturers of horizontal water transfer pumps recommend this type to transport water over short distances or small heads.

Figure: Single stage horizontal water transfer pump.

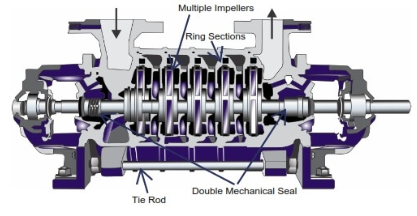

Multistage horizontal water transfer pump

A multistage pump is designed with more than one impeller set. The impellers are arranged in series from left to right. Each set of impellers serves as a stage or fluid flow chamber. The water flows from the first stage to the second stage and goes until it exits the last step. For each stage, the water pressure increases, and it keeps growing until it leaves the last stage. This type of pump is potent and thus can transfer water over large heads. However, this pump is expensive relative to the single-stage type. It is also more costly to repair and clean due to the many impellers.

Figure: Multistage horizontal water transfer pump.

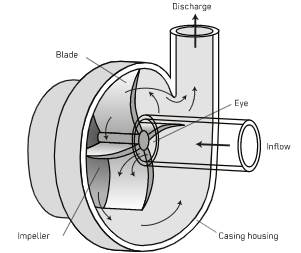

Radial flow horizontal water transfer pump

This is the pump in which the water enters axially and leaves radially. This pump has a high flow rate for high heads.

Figure: Radial flow horizontal water transfer pump.

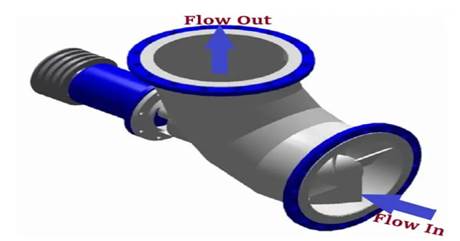

Axial flow horizontal water transfer pump

The water in this pump enters radially, but it is discharged axially, as shown below. This pump has a high discharge rate at a low head.

Figure: Axial flow horizontal water transfer pump.

Mixed flow horizontal water transfer pump

As the name suggests, this pump employs axial and radial fluid flow. When the water enters the pump, it flows along the impeller axis for half the distance, after which it starts moving vertically to the axis. This pump can pump water at a high flow rate. It can also pump water with solid particles.

Figure: Mixed flow horizontal water transfer pump.

Applications of horizontal water transfer pumps

- They are used to transport water used in irrigation.

- They are used to transport water for domestic and commercial use.

- They are used in vehicle washing applications.

- Horizontal water transfer pumps are used to transport water for swimming pools.

- They are used in firefighting applications.

- They are used to drain floods.

- They are used in construction applications.

- Horizontal water transfer pumps are used as pressure boosters in water transportation.

Advantages of horizontal water transfer pumps

- These pumps are easy to clean and repair as they can be easily accessed, unlike vertical pumps.

- They are most common in the market, which makes their spare parts highly available.

- Horizontal water transfer pumps can be used for fresh and clean water applications.

- They have a high volume flow rate.

- These pumps are free from fluid leakage.

- It occupies less vertical space and is thus suitable for installation with limited vertical space.

- These pumps are versatile in size as they can be either small or large, ideal for high and low heads.

- Horizontal water transfer pumps are cheaper relative to reciprocating pumps.

The disadvantage of a horizontal water transfer pump

- This type of pump is prone to cavitation problems.

- Improper alignment of the pump and motor shaft reduces pump efficiency and causes rapid wear.

- Horizontal water transfer pumps are prone to impeller damage.

Disadvantages of centrifugal Monoblock water pumps

- These pumps are prone to cavitation.

- The impellers are prone to wear and need to be replaced.

- The pump needs to be primed unless it is self-priming.

Troubleshooting a horizontal water transfer pump

The pump does not start

- No power in the motor. Check the power from the mains supply is connected to the motor.

- Motor is damaged. Repair the motor or replace it as necessary.

- The motor rotates in the opposite direction. Check the motor shaft direction of rotation and ensure it matches the arrow indicated on the pump casing.

- The pump is not primed. Ensure the pump is sufficiently primed.

The pump runs but no water flow

- Closed discharge valve. Open the discharge valve.

- Closed suction valve. Open the suction valve.

- Blockage in the pump. Disassemble the pump following instructions from the horizontal water transfer pump manufacturer and clean off blocking materials.

- Wrong direction of rotation. Change the motor direction of rotation.

The pump does not prime

- Clogged impeller. Open the pump and clean off the impeller.

- Blocked strainer or suction pipe. Check the filter or suction pipe and remove any blocking materials.

- Leakage through the suction pipe. Repair the suction line.

- The suction line is too high. Reduce the suction line.

Low fluid flow

- The discharge valve is not fully open. Open the discharge valve accordingly.

- The suction valve is not fully open. Open the suction valve fully.

- Leakage through the suction line. Repair the suction line.

- Blockage inside the pump. Disassemble the pump and clear any blocking materials.

The pump produces a lot of noise or vibration

- Improperly aligned pump and motor shaft. Align the motor and pump shaft properly.

- The impeller is partially clogged. Open the pump interior and clear off clogging materials.

- Worn out bearings. Replace the bearings.

- The pump foundation is not rigidly supported. Check the pump foundation and tighten it.

- Discharge or suction pipe not anchored firmly. Anchor the suction/discharge pipe firmly.

Pump bearings running too hot

- Improper shaft alignment. Align the motor and pump shaft properly.

- Lack of lubrication. Lubricate the bearings adequately.

Summary

A horizontal water transfer pump is a type of centrifugal pump installed in a horizontal orientation. The pump creates a vacuum when impellers rotate at high speed. This vacuum leads to a pressure difference with atmospheric pressure. Atmospheric pressure on the surface of water forces the water into the pump. This type of pump is suitable for transporting both salty and fresh water.

Horizontal water transfer pump manufacturers produce various sizes of these pumps that suit different water flow rates from small to large. There are various horizontal water transfer pumps, including self-priming, single-stage, and multistage pumps. The advantages of purchasing a horizontal water transfer pump are that it is easy to clean and repair, easy installation, cheap, readily available, and versatile in size. Applications of this pump include firefighting, domestic and commercial water supply, construction, irrigation, and draining flooded areas among others.