Vertical Multistage Pipeline Centrifugal Pump

What is a vertical multistage pipeline centrifugal pump?

A vertical multistage pipeline centrifugal pump is used to overcome height differences and friction losses when transporting crude oil and petroleum products. This pump and its motor are installed in a vertical orientation. The pump is designed with several impellers to make it more powerful for transporting fluid for a large head. The pump lies in the category of centrifugal pumps. Such pumps rotate the impellers at high speed to draw fluid into the pump. Vertical multistage pipeline centrifugal pump manufacturers design the pump from high-strength metallic materials that ensure the pump is vital to withstand high pressure and temperature. Depending on the application area, the pump design can have a close-coupled or long-coupled design. A vertical multistage pipeline centrifugal pump is suitable for use with limited floor space applications.

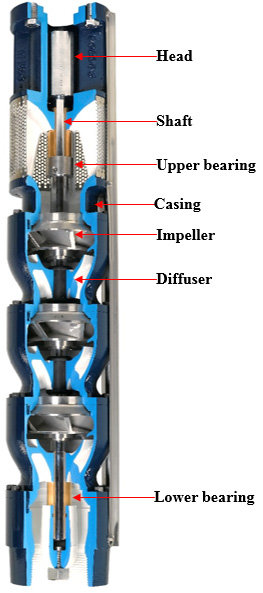

Figure: Vertical multistage pipeline centrifugal pump

Components of a vertical multistage pipeline centrifugal pump

Electric motor

Vertical multistage pipeline centrifugal pump manufacturers design the pump to operate on a DC or AC motor, depending on the customer’s preference and power availability. The motor is the power supply for the pump. It works by converting electrical energy from the mains supply to mechanical energy. The mechanical energy is responsible for rotating the pump shaft to create a vacuum in the pump.

Pump shaft

The shaft is mounted inside the pump and supported on bearings. The shaft transmits motor power to the pump impellers to allow impeller rotation and the creation of a vacuum. Vertical multistage pipeline centrifugal pump manufacturers usually produce the shaft from high-strength metallic materials such as stainless steel and carbon steel. Such materials are solid; thus, the shaft becomes strong enough to transmit a large amount of torque without failing.

Impellers

Impellers are the core components of the pump that create a vacuum and kinetic energy on the fluid. The pump is designed with several impellers, and each impeller forms a chamber inside the pump. All the impellers rotate at the same speed since they are mounted on the same shaft. The impellers have backward curved vanes that prevent the impeller from overloading the motor.

Bearings

The bearings support the impeller hydraulic loads, the mass of the impeller and shaft, and shaft coupling loads. The bearings also ensure the lateral shaft deflection and axial end movement are kept within acceptable limits for the shaft seal and impeller.

Mechanical seals

Mechanical seals are vital to enhancing pump integrity by preventing fluid leakage and contaminants from entering the pump.

Pump casing

The pump casing is an external component used to seal fluid and pressure inside the pump from the outside. The casing is also vital since it affects the pump’s efficiency. Vertical multistage pipeline centrifugal pump manufacturers design the case depending on the type of pump.

Coupling

Coupling is a component used to connect the motor shaft to the pump shaft. The coupling is critical in enhancing pump efficiency if it is aligned perfectly. Any slight misalignment may lead to bearings overheating and low pump performance.

Suction pipe, filter, and valve

The suction valve is used to control fluid flow into the pump. The suction pipe connects the pump to the source of the liquid. The work of this pipe is to convey fluid from the storage tank/source to the pump. The filter, a strainer, filters unwanted solids from entering the pump.

Discharge valve and pipe

The discharge valve regulates the liquid that leaves the pump into the piping system. The discharge pipe connects the pump to the pipeline, transporting fluid to the required destination.

Figure: Components of a vertical multistage pipeline centrifugal pump

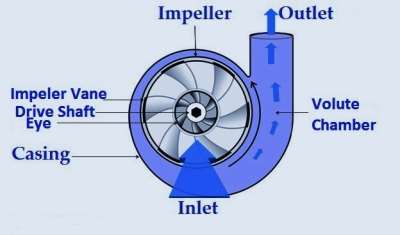

How does a vertical multistage pipeline centrifugal pump?

A vertical multistage pipeline centrifugal pump operates by rotating the impellers at the same speed as the motor shaft, which creates a vacuum in the pump. The vacuum is a state of low pressure relative to the atmospheric pressure. The vacuum forces fluid in the tank into the pump due to atmospheric pressure difference. The fluid enters the pump, where it meets the first impeller, spinning at high speed. With an impeller’s high kinetic speed, the liquid absorbs some kinetic energy, increasing its velocity. The pressure energy increases as the fluid proceeds to the next impeller along the diffuser while the velocity starts reducing. The exact process of pressure energy increase continues until the fluid leaves the last stage.

Figure: Working of a vertical multistage pipeline centrifugal pump

Types of vertical multistage pipeline centrifugal pump

Magnetic drive vertical multistage pipeline centrifugal pump

This pump uses magnets to connect the pump shaft and the motor shaft. The magnetic technology involves two magnets; one is placed outside the pump, and the other is inside the pump. The outer magnet is attached to the motor shaft. After starting the pump, the motor shaft spins at high speed, and the external magnet rotates at the same rate. Due to the magnetic field pattern of magnets, the inner magnet starts spinning. The rotation of the internal magnet causes the pump shaft to rotate at the same speed. The pump shaft turns the pump impeller to create a vacuum that draws fluid into the pump.

The advantage of a magnetic drive vertical multistage pipeline centrifugal pump is that it is highly reliable in preventing fluid leakage. Using magnetic coupling instead of mechanical seals prevents any fluid from leaking. It also ensures zero leakage to the liquid, which for other pumps, may lead to environmental damage or injuries to the pump operator.

Immersion vertical multistage pipeline centrifugal pump

Vertical immersion multistage pipeline centrifugal pumps are a type of pump in which the motor is separated from the fluid pumped. The motor is mounted at the top of the pump shaft. This pump is mostly used in pits or tanks in place of pumps. These pumps have a long shaft that connects the motor and the pump. Vertical multistage pipeline centrifugal pump manufacturers design these pumps with bearing support to reduce radial forces to prevent the shaft from whipping due to the shaft torque. This pump is designed for use in low-flow designs. The pipeline is connected to the discharge port at an angle of 90o to the suction port.

Figure: Vertical immersion multistage pipeline centrifugal pump.

Vertical in-line multistage pipeline centrifugal pump

This pump is designed to align the suction and discharge ports straight with the pipeline. This pump design helps to enhance smooth fluid flow through the system. Vertical multistage pipeline centrifugal pump manufacturers recommend this pump for use where there are small installation spaces and rooms. This pump is suitable for use in applications that involve fluids of low viscosity. This pump is mostly installed suspended like control valves.

Figure: Vertical in-line multistage pipeline centrifugal pump.

Applications of vertical multistage pipeline centrifugal pump

- These pumps are used in the chemical processing and manufacturing products such as colorants, plastics, hydrocarbons, and detergents.

- Vertical multistage pipeline centrifugal pumps are used in water injection oil fields meant to recover oil in place.

- They are used to transport oil and fuel products over long distances.

- They are used in water supply and desalination plants.

- Vertical multistage pipeline centrifugal pumps are used in offshore platforms.

- They are used to supply water and steam in power plants.

- They are used in the transportation of hydrocarbons.

- Vertical multistage pipeline centrifugal pumps are used to transport heavy oil and diesel fuel.

- They are used in drilling mud.

- They are used in the transportation of wax and oil mixture.

- These pumps are also used in polymer and polymer flooding transfer.

Advantages of vertical multistage pipeline centrifugal pumps

- These pumps are suitable for deep tanks, well emptying, and sumps. These pumps can be designed with long shafts that allow the pump to operate while immersed in the fluid and reduce the need for priming.

- Vertical multistage pipeline centrifugal pumps produce high-pressure energy due to the several impellers used. The high-pressure energy helps the pump transfer the fluid long distances.

- These pumps are of compact design that helps to save on space. As such, they can be installed in applications with limited floor space.

- They are suitable for use in applications that involve flammable fluids.

- They can operate on corrosive fluids, especially stainless steel pumps.

- Vertical multistage pipeline centrifugal pumps are easy to maintain relative to the submerged pumps.

- They are versatile for various industrial applications.

Disadvantages of vertical multistage pipeline centrifugal pumps

- These pumps are hard to repair and clean due to the vertical orientation and many impellers used.

- They need significant headroom for installation and maintenance.

- Vertical multistage pipeline centrifugal pumps are expensive relative to single-stage pumps.

- They are prone to vibrations, especially those that have a long shaft.

Troubleshooting vertical multistage pipeline centrifugal pump

Zero fluid flow rate through the pump

- Air in the suction line or the pump. Prime the pump to remove the air.

- Too high suction lift. Reduce the suction lift if possible.

- Incorrect pump speed. Check the motor frequency and voltage are as recommended by the vertical multistage pipeline centrifugal pump manufacturer.

- Wrong direction of motor rotation. Ensure the direction of motor rotation matches the rotation arrow on the pump.

- Clogged suction valve, impeller, or filter. Clean the impeller, filter, or check valve as necessary.

- Closed suction valve. Open the valve.

- Closed discharge valve. Open the discharge valve.

- No power supply on the motor. Check the power supply cables have power.

- Damaged motor. Replace the motor or call an electrician to make repairs.

- Damaged impellers. Replace the impellers.

- Poor motor wiring. Call electrical company or electrician to correct the motor cables.

Reduction in fluid flow

- Air ingress through the suction line, shaft seal, or suction port. Repair the suction line and port or replace the seals as necessary.

- Clogged valve, impeller, or filter. Clean the impellers, and check the valve and filter.

- The suction valve is partially open. Open the suction valve fully.

Bearings overheating

- Poorly aligned coupling. Align the pump shaft and coupling properly.

- Excessively torqued bearing cover. Loosen bearing cover.

- No lubrication on the bearings. Lubricate the bearings frequently.

- The pumped fluid is low. Increase the fluid flow to safe levels recommended by the vertical multistage pipeline centrifugal pump manufacturer to aid in cooling the pump and bearings.

The pump makes a lot of vibrations/noise

- Clogged impeller. Clean off materials blocking the impeller.

- Defective or worn-out impeller. Replace the impeller.

- Poorly aligned coupling and shafts. Align the shafts and coupling properly.

- Loose pump supports. Tighten the pump supports.

- Oblique pump shaft. Replace the shaft.

Summary

A vertical multistage pipeline centrifugal pump transports fluids over long distances. This pump has several impellers that work together to create high-pressure energy that can transfer the liquid to the required location. The pump is installed in a vertical orientation together with the motor. The pump operates by getting power from the motor. The motor shaft rotates at high speed when the pump is started. Due to the motor speed, the pump impellers spin at the same speed, creating a vacuum. The vacuum helps to force fluid to move from its source into the pump, passing through the impellers and creating high-pressure energy.

Vertical multistage pipeline centrifugal pump manufacturers design various types of this pump which include magnetic drive pump, in-line pump, and immersion pump, among others. Applications of this pump include the transfer of chemical processing, water injection, transport of oil and fuel products, water supply and desalination systems, and transport of hydrocarbons, among others. This pump’s advantages are occupying small floor space, producing high-pressure energy, being highly versatile in various sizes, and resisting corrosion.