Water Pressure Booster Pump

What is a water pressure booster pump?

A water pressure booster pump is a type of centrifugal pump for increasing the water pressure and flow rate in water supply systems. Many factors contribute towards decreased water pressure, including gravity slowing down the fluid, higher elevation, plumbing problems, long distance from the water source, and low pressure from local water supply systems. The Water pressure booster pump helps to solve the challenge of low water pressure by providing the extra boost needed to raise the pressure and volume flow of water to the desired level. It works with other pumps in the existing pumping systems because it cannot push water to the targeted area or height. Water pressure booster pumps are perfect for low-pollution water supply systems. They have been used in private and residential homes to generate enough pressure to carry water from a storage tank to faucets, shower heads, etc. Many military, municipal, commercial, and industrial applications also use water pressure booster pumps.

Figure: Showing the configuration of a water pressure booster pump

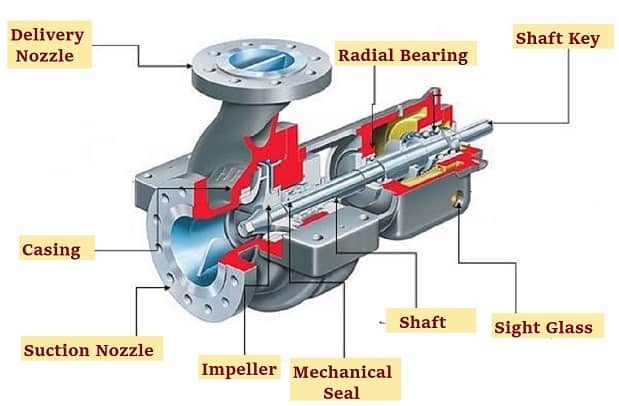

Components of a water pressure booster pump

Motor

The water pressure booster pump works with small alternating current (AC) single-phase induction motors. The primary function of the electric motor is to provide mechanical energy for rotating the pump impeller. The electric motor is close-coupled to the pump head in most water pressure booster pumps.

Pump casing

The pump casing house the pump’s internal components and helps to convert the high kinetic energy (imparted on the water by the impeller) into a pressure head. Water pressure booster pump manufacturers create the pump casings from ductile cast iron, cast steel, or duplex stainless steel.

Shaft

The shaft is a rotary mechanical component centrally located in the pump and riding on bearings. It supports the impeller and connects the pump rotor assembly to the motor through coupling.

Impeller

The impeller displaces the fluid that comes in through the pump inlet and exits through the outlet. It comprises a series of backward curved vanes and can be either a radial flow open-type or radial flow closed-type impeller.

Inlet and outlet

The pump inlet connects with the waterline while the outlet connects to the household water distribution piping

Pressure or flow-sensing devices

The pressure flow sensing devices help to measure the pressure and flow rate of the fluid moving through the pump and to adjust accordingly.

Figure: Components of a water pressure booster pump

How does a water pressure booster pump work?

During operation, the pump impeller is mechanically powered through an electric motor. The impeller is directly coupled to the electric motor via a shaft and rotates at motor RPM. When the water from the supply line strikes the impeller vanes, it is imparted with high kinetic energy and accelerated towards the pump casing due to the centrifugal force acting on the impeller. In the pump casing, the water speed slowly decreases due to the gradually reducing flow path size, and the high kinetic energy converts into a high-pressure head. Finally, the water leaves the pump casing through the pump outlets and enters the delivery pipe to be transferred to the desired location.

Types of water pressure booster pumps

End-suction water pressure booster pump

An end-suction water pressure booster pump features an axial suction line and a discharge outlet oriented at 90 degrees to the suction line. It can be long-coupled (separate coupling & motor) or close-coupled (where the motor is in the same unit as the pump). Water pressure booster pump manufacturers usually design the end suction pump for horizontal mounting. It is the most common water pressure booster pump design and has a compact construction and simple operation.

Figure: End suction water pressure booster pump.

Inline water pressure booster pump

An inline water pressure booster pump contains the suction and discharge nozzles resting in a straight line of piping or in line with each other inside a pump casing. The direction of fluid flow does not change inside the inline water pressure booster pumps. Water pressure booster pump usually develop the inline pump as a single-stage, single-suction centrifugal pump. Inline water pressure booster pumps are typically installed along the pipeline like valves. They are small and take up less floor space.

Figure: Showing the configuration of an inline water pressure booster pump.

Water pressure booster pump with an explosion tank

This type of water booster pump comes with an expansion tank called a hydropneumatic tank to enhance a boosted system. The tank provides extra space for water when it expands, preventing the water pressure booster pump from cycling on and off each time the faucet is turned on. The explosion tank holds the drawdown water, which flows out of the tank before the pump turns back on. This pump is used in private wells to reduce pump cycles and elevate water pressure significantly.

Figure: Showing the configuration of a water pressure booster pump with an explosion tank.

Horizontal water pressure booster pump

A horizontal water pressure booster pump has its shaft oriented horizontally within the pump casing. The horizontal water pressure booster pump can be safely coupled with different prime movers such as electric motors, turbines, and fuels powered engines. It has low headroom requirements; hence suitable for indoor applications where vertical space is limited. This type of booster pump is often simple to maintain because the parts are easily accessible. However, a horizontal water pressure booster pump takes more floor space, and the working temperatures and pressure are relatively lower than the vertical inline booster pump.

Figure: Showing the configuration of a horizontal water pressure booster pump.

Vertical water pressure booster pump

The vertical water pressure booster pump contains a vertically oriented pump shaft, which is radial split and overhung. It suits applications with confined spaces because it takes up a small footprint. It can handle water at high-temperature and pressure than its horizontal counterpart. However, the over-hung shaft design is problematic under high suction pressure because it is challenging to balance the axial thrust.

Figure: Showing the configuration of a vertical water pressure booster pump.

Applications of water pressure booster pump

Water pressure booster pump manufacturers develop units to elevate water pressure for everything from domestic applications like bathroom showers and taps to industrial systems and commercial applications, such as shower blocks, portable toilets, and hotels. They are essential components in various water engineering systems.

- Water pressure booster pumps are used to increase the water pressure and flow rate in domestic commercial and industrial water supply systems.

- They are used as circular booster pumps in bathrooms for cold and hot water.

- They are used in homes to increase the flow from a low-recovery well to a storage tank.

- They are used in constant-pressure water supply systems.

- They are also used in farmland irrigation and drainage.

- They also apply to power plant water supply and drainage.

- They are used as firewater pumps to support of firefighting equipment

Advantages of water pressure booster pump

- Water pressure booster pumps have a simple and compact construction, requiring relatively small installation space.

- They are reasonably energy efficient because they are not always in operation and kick into action when the user turns on the faucet to boost the pressure of the water supply.

- They have high reliability and efficiency.

- They do not have pressure losses.

- They have Low life cycle cost due to minimal maintenance requirements.

- The pump can handle a wide range of pressure and flow rates.

- They provide cavitation-free operation.

- They provide a continuous and steady flow.

Disadvantages of a water pressure booster pump

- The water pressure booster pump requires a strict balance between the water flow rate

If the water flow rate in the mainline exceeds the capacity of the water pressure booster pump, the pump may over speed or become ineffective.

- Water pressure pumps are subject to mechanical seal problems due to gas accumulation in the seal chamber, which damages mechanical seals.

- Seal leakage above the pump casing can cause the pump to corrode.

Troubleshooting a water pressure booster pump

The pump does not start

- There is a fault in the pump wiring, e.g., loose connections or broken wiring. Inspect and fix loose connections or replace the broken wires.

- The circuit breaker is open, or the fuse is blown-out. Inspect the water pressure booster pump for a blown-out fuse and replace it if necessary. Shut the circuit breaker.

- The voltage is irregular due to dirt or corrosion at the pressure switch. Inspect the pressure switch and clean it of any debris or pollution.

- The fuse receptacles are dirty or corroded. Inspect and clean fuse receptacles if necessary.

- The power supply to the panel is insufficient. Ensure that the voltage and current supply to the pump match the amount specified in the water pressure booster pump manufacturer’s manual.

The pump overheats and shuts off

- The motor voltage does not match the line supply voltage. Check the motor supply voltage against the voltage specified by the water pressure booster pump manufacturer on the nameplate.

- The impeller collides with the pump casing or lacks a free rotation. Disassemble the pump and align the impeller correctly.

- There is too much thrust due to mechanical failure inside the pump. Inspect the pump assembly and correct any shortcomings.

- The motor has the wrong wire sizes. Consult the national electrical codes for a helpful guide on the correct wire sizes and circuit protection devices.

- The pump bearings are worn-out. Inspect and replace the bearings if necessary.

- The pump is operating at very low capacity. Make sure that the pump operated at the rated capacity, according to water pressure booster pump guide.

The pump vibrates or produces too much noise

- The pump assembly is loose. Tighten pump components to the torque level recommended by the water pressure booster pump manufacturers.

- There are unbalanced components in the vertical turbine pump. Inspect and rebalance the elements.

- Foreign matter in the impeller. Open and clean the pump to remove foreign materials.

- The water pressure booster pump’s foundation is not rigid. Check vibration and hollowness on the base frame.

- The pump shaft is bent. Dismantle and inspect or replace the pump.

- The impellers are severely worn-out or defective. If necessary, inspect the impellers and replace any worn-out impeller with another from the water pressure booster pump manufacturers.

The pump driver is overloaded

- The motor has shortcomings, such as poor ventilation, wrong positioning, etc. Inspect the electric motor and do necessary repairs.

- The pump speed is too high. Reduce the pump’s rotational speed.

- Fluid density or viscosity is too high. Make sure that the pump matches the application.

- The packing wound is fixed too tightly. Loosen nuts on packing glands to the water pressure booster pump manufacturer’s recommended torque level.

- Mechanical friction within the pump. Repair any obstruction or deflection.

Summary

A water pressure booster pump is a type of centrifugal pump that helps to elevate the water pressure and flow rate in water supply systems. It creates the extra boost needed to raise the pressure and volume flow of water to the desired level, helping to tackle the challenge of low water pressure, which occurs due to gravity, higher elevation, and plumbing problems, among other reasons. Water pressure booster pumps work with other pumps in pumping systems because they cannot move water to the targeted area or height independently. They are mainly used to elevate water pressure in domestic, residential, and commercial applications. Water pressure booster pump manufacturers offer different designs, such as end suction pump, inline pumps, and horizontal and vertical configurations. The water pressure booster pump is also available with an explosion tank, preventing the device from cycling on and off each time the faucet is turned on. Water pressure booster pumps require relatively small space for installation and are reasonably energy efficient.