High-Pressure Boiler Feed Water Pump

What is a high-pressure boiler feed water pump?

A high-pressure boiler feed water pump is a type of centrifugal pump used to transport the feedwater at high pressure from the deaerator tank to the boiler. It is an essential component of the boiler systems, which are used to produce steam for various industrial and residential uses. Most high-pressure boiler feed water pumps are multistage pumps, i.e., they employ several impellers to generate the high pressure necessary to feed the boiler. Generally, the high-pressure boiler feed water pump manufacturers develop the units with a between-bearing design where bearings on each end support the pump shaft. The impellers lie in between the bearings. High-pressure boiler feed water pumps provide a reliable service delivering high pressure at medium to low capacities without cavitation. They can operate at low speed (about 1750 RPM), which helps to protect the pump components from abrasion and wear. These pumps’ net positive suction head requirement (NPSHr) can be as low as 3ft.

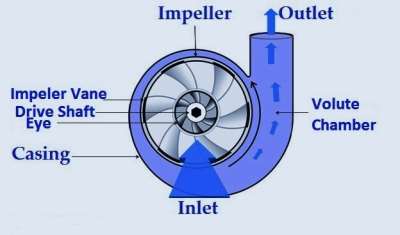

Figure: Showing the configuration of a high-pressure boiler feed water pump

Components of a high-pressure boiler feed water pump

Electric motor

In a high-pressure boiler feedwater Pump, the electric motor is connected to the pump body by mechanical coupling. The electric motor is the source of power for the pump.

Pump casing

The pump casing, also called the housing, is the major stationary component of the high-pressure boiler Feed water pump, covering the impeller and other internal parts. The pump casing also helps to convert the pumped liquid’s kinetic energy into the pressure head and to direct the flow to the discharge connection. The high-pressure boiler feed water pump manufacturers create the pump casings from iron or duplex stainless steel.

Shaft

The shaft is a rotary mechanical component centrally located in the pump and riding on bearings. It supports the impeller and connects the rotor assembly to the motor via coupling.

Impellers

The impeller consists of backward-curved vanes and rides on the pump shaft. Its principal function is to impart kinetic energy to the pumped liquid and move it through the pump body. An impeller can be manufactured from cast iron, ductile cast iron, or stainless steel. The high-pressure boiler feed water pump manufacturers assemble the impellers with delicate clearance between the vanes and the pump casing to avoid slippage and recirculation.

Bearings

The high-pressure boiler feed water pump manufacturers fit the units with angular contact ball bearings, which are oil-lubricated and designed to handle axial thrusts in both directions. The bearings help to hold the shaft and the rotor assembly in place and align them correctly with the fixed ends under the radial and axial loading.

suction inlet and discharge outlet

The pumped fluid enters the pump through the suction inlet and exits through the discharge outlet, which links with the delivery connections.

How does a high-pressure boiler feed water pump work?

The high-pressure boiler feed water pump transports water from the deaerator tank or the condenser to the boiler. Its operation is based on converting mechanical energy into hydraulic energy by using the centrifugal force of a rotating impeller. When the pump starts running, the impeller rotates with the priming liquid inside the pump casing, creating a vacuum at the impeller’s eye, which allows the boiler feed water to flow into the pump casing. As soon as the liquid enters the impeller eye, the centrifugal force acting on the impeller blades moves it radially outwards, away from the impeller center of rotation, at high tangential velocity. The swirling flow at the exit of the impeller then enters into the diffuser, where the extreme fluid flow speed decelerates due to the gradually expanding flow channel. The high kinetic energy of the boiler feed water also converts into a high-pressure head. Finally, the boiler feed water discharges from the pump under elevated pressure into the boiler, and the cycle continues.

Figure: Working of a high-pressure boiler feed water pumps

Types of high-pressure boiler feed water pumps

The high-pressure boiler feed pump has two main types: vertical and horizontal. The classification is based on the orientation of the shaft within the pump. Both pumps feature a multistage design and a radially split casing with a vertical joint relative to the shaft. However, the horizontal high-pressure boiler feed pump can generate higher pressure than its vertical counterpart.

Vertical high-pressure boiler feed water pump

A vertical high-pressure boiler feed water pump consists of a vertically oriented pump shaft coupled to an electric motor. This pump features a stamped stainless-steel construction. The pump operator can easily alter the net positive suction head (NPSH) for the vertical high-pressure boiler feed water pump to cater to a wide range of applications. However, vertical high-pressure boiler feed water pumps are difficult to install and maintain because they require a lot of headroom. The overhung shaft may be problematic at high suction pressure as it becomes challenging to balance the axial thrust.

Figure: Vertical high-pressure boiler feed water pump.

Horizontal high-pressure boiler feed water pump

A horizontal high-pressure boiler feed water pump features a horizontally oriented pump shaft, which may be coupled to a turbine, electric motor, or engine. The heavy-duty pump is mainly made of cast steel. The pump is easier to install and maintain because the spacer coupling provides space for a maintenance operation, and the pump’s internal components are easily accessible. However, Horizontal high-pressure boiler feed water pumps have limited NPSH. Because of their low headroom, horizontal centrifugal pumps suit indoor applications where limited vertical space.

Figure: Horizontal high-pressure boiler feed water pump.

Applications of high-pressure boiler feed water pumps

High-pressure boiler feed water pumps are widely used in boiler systems that produce steam for various industrial and process applications, including building heat, sanitation processes, power generation, and many more. In addition to the boiler systems, high-pressure boiler feed water pumps apply to the transfer of liquids in many other systems, such as washing, cooling, air-conditioning, water supply, firefighting, fuels, solvents, etc. Typical uses of the pumps include the following.

- High-pressure boiler feed pumps are used to supply fresh water from the condenser to a boiler. Condensation that forms in the boiler systems is typically recycled and fed back into the boiler with condensate return pumps.

- The high-pressure boiler feed water pump is used to maintain the desired amount of water in the steam boiler to prevent failure.

- They are used for intermittent or continuous high-pressure pumping of hot chemically treated feed water.

Advantages of high-pressure boiler feed water pump

- high-pressure boiler feed water pumps can tolerate high temperatures and pressure.

- The between-bearing design of the high-pressure boiler feed water pump enhances a balanced shaft loading.

- They have less maintenance and operation cost.

- They prevent thermal shock to the boiler or the deaerator by raising the temperature of the feed water.

- They have significant energy savings and operating efficiency because they raise the temperature of the boiler feed water.

- The pump can be stopped if there is no need for a feed water supply.

- They do not have pressure losses.

- They provide a steady and continuous fluid flow output.

- The vertical type has a variable NPSH and thus can cater to various applications.

- They are highly reliable.

- They are easy to install and maintain.

- They provide cavitation-free operation.

Disadvantages of high-pressure boiler feed water pump

- High-pressure boiler feed water pumps have high initial acquisition and installation costs.

- The outlet pressure is too high and may damage the matching equipment. Pressure-reducing valves must be fitted in the pipeline to prevent any damages from occurring, which further raises the cost of necessary equipment.

- The high-pressure boiler feed water pump requires a large motor to achieve the required outlet pressure. Large electric motors consume more power.

Troubleshooting high-pressure boiler feed water pump

The pump won start

- The voltage is irregular due to dirt or corrosion at the pressure switch. Inspect the pressure switch and clean it of any debris or pollution.

- There is a blown-out fuse or tripped circuit breaker. Inspect the high-pressure boiler feed water pump for a blown-out fuse and replace it if necessary.

- The fuse receptacles are dirty or corroded. Inspect and clean fuse receptacles if necessary.

- The power supply to the panel is insufficient. Ensure that the voltage and current supply to the pump match the amount specified in the high-pressure boiler feed water pump manufacturer’s manual.

The pump loses its prime after starting

- The suction lift is too high. Reduce the suction lift by lowering pump elevation or increasing the water level.

- There is an excessive amount of air in the liquid. Be sure to find out the reasons and eliminate them. For instance, air may be entering via the suction joints.

- The water seal pipe is clogged. Clean or change the water seal pipe.

The pump delivers insufficient capacity

- There is air pocked in the suction line. Ensure that the pipe is filled with the pumped liquid. Make sure there are no concentric to avoid negative suction.

- The pump or suction pipe is not filled with water. Inspect the foot valve for leakage and correct it.

- The total head of the system is higher than the design head of the pump. Measure the pump head using a pressure gauge. Refer to the high-pressure boiler feed water pump manufacturers’ manual for the pump’s design pressure head.

- Clogged impeller. Inspect the impeller and remove any material.

- The pump is operating in reverse. Check that the direction of the motor rotation matches the direction indicated by the high-pressure boiler feed water pump manufacturers on the nameplate. Be sure to reverse the motor polarities.

The pump vibrates, or it is noisy

- Foreign matter in the impeller. Open and clean the pump to remove foreign materials.

- There are unbalanced components in the vertical turbine pump. Inspect and rebalance the elements.

- The high-pressure boiler feed water pump’s foundation is not rigid. Check vibration and hollowness on the base frame.

- The pump assembly is loose. Tighten pump components to the torque level recommended by the high-pressure boiler feed water pump manufacturers.

- The impellers are severely worn-out or defective. If necessary, inspect the impellers and replace any worn-out impeller with another one from the high-pressure boiler feed water pump manufacturers.

- The pump shaft is bent. Dismantle and inspect or replace the pump.

The pump overheats and seizes

- The pump is not primed. Ensure that casing is filled and water comes out from the air cock.

- The viscosity of the liquid is different from the design. Ensure the pump applies to the correct fluid following the high-pressure boiler feed water pump manufacturer’s manual and product data-sheet.

- Rotating parts are rubbing on the stationary part. Disassemble the pump and correct the assembly.

- The pump bearings are worn-out. Inspect and replace the bearings if necessary.

- There is too much thrust due to mechanical failure inside the pump. Inspect the pump assembly and correct any shortcomings.

Summary

A high-pressure boiler feed water pump is a pump used to transport the feedwater at high pressure from the deaerator tank to the boiler. It is a crucial component of boiler systems. Most high-pressure boiler feed water pumps are multistage pumps, which employ several impellers to perform the pumping action and raise the high pressure needed to feed the boiler. The high-pressure boiler feed water pump manufacturers develop the units with a between-bearing design to ensure a balanced shaft loading. High-pressure boiler feed water pumps are evident in boiler systems that produce steam for various industrial and process applications, including building heat, sanitation processes, power generation, and many more. Apart from the boiler systems, high-pressure boiler feed water pumps apply to transfer liquids in many other applications, such as washing systems, cooling, air-conditioning systems, water supply, firefighting, etc. High-pressure boiler feed water pumps can tolerate high temperatures and pressure and have low maintenance and operation costs.