Self-priming Dirty Water Pump

What is a self-priming dirty water pump?

A self-priming dirty water pump is designed to pump water without requiring manual priming. The pump needs priming after acquiring it from the market. After pumping water for the first time, it stores some for the following pumping process. However, if it stays without pumping water, it is recommended to do priming first. The pump has a reservoir that stores priming water. The priming process is meant to expel air in the pump and the suction line. With the air inside the pump, it becomes very hard for atmospheric pressure to force water from the storage into the pump. The pump power comes from a prime mover, mostly an electric motor or diesel engine. The self-priming dirty water pump is suitable for pumping water that has solid particles, such as sewage and other forms of wastewater. It is easy to install and repair. Self-priming dirty water pump manufacturers produce pumps of various sizes to allow for different flow rates and flow heads.

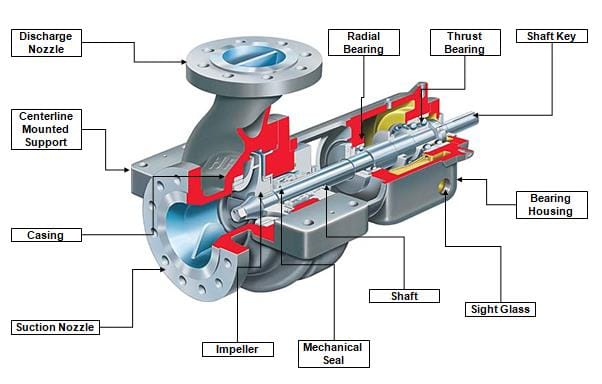

Figure: Self-priming dirty water pump

Components of a self-priming dirty water pump

Prime mover

The work of the prime mover is to provide the mechanical power needed to move the water. The prime mover is either an electric motor or an IC engine. Energy from the prime mover to the pump is transmitted using a shaft.

Shaft

The shaft is usually solid and transmits power from the prime mover to the pump. Self-priming dirty water pump manufacturers produce the shaft from high-strength materials such as carbon steel and stainless steel. Such high-strength materials ensure the shaft is strong enough to transmit the torque the pumps need to move water to your location.

Coupling

Coupling is a mechanical component in pumps that connect the prime mover drive shaft to the pump shaft to enhance power transmission. The coupling helps to introduce mechanical flexibility that provides tolerance for shaft misalignment.

Bearings

Bearings support shaft, impeller hydraulic loads, and loads on shaft coupling. They help to keep shaft lateral deflection and axial end movement within allowable limits for the shaft and impeller seals.

Impeller

The impeller is the component responsible for imparting mechanical energy to the water. It operates while mounted on the pump shaft. When the pump is started, the shaft rotates, and thus, the impeller spins at the same high speed. Self-priming dirty water pump manufacturers design the impellers for this type of pump from high-strength materials like steel to ensure it is able to withstand high hydraulic loads and solid particles.

Casing

The casing is a shell that houses the impeller and other internal parts of the pump. The casing design depends on the type of pump. The casing is designed such that the flow area increases towards the discharge end. Such a design helps reduce water velocity to increase pressure since pressure increases with a decrease in speed. The high pressure is responsible for moving water to your destination.

Foot valve and suction pipe

The foot valve is a one-way valve that controls water flow into the pump and also prevents water from flowing backward when the pump is turned off. The suction pipe connects the pump to the water tank containing water or the water well. Self-priming dirty water pump manufacturers include a filter on the suction pipe that helps to filter out those large-sized solids that the pump cannot handle.

Discharge valve and pipe

The discharge pipe connects the pump to the pipeline for water to flow in the pipe network. The discharge valve controls the amount of water flowing in the pipe network.

Figure: Components of a self-priming dirty water pump.

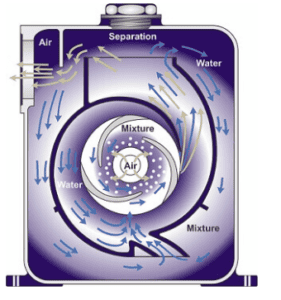

Working on a self-priming dirty water pump

A self-priming dirty water pump operates by first expelling all air in the pump. The pump is first turned on to remove the air, causing the impeller to rotate. Impeller rotation causes a partial vacuum in the pump that helps to move some water and air into the pump from the suction line. The air and water mixture moves up with air on top due to its low density. As the air-water mixture moves towards the pump’s discharge, the air is expelled to the discharge port, leaving water behind. Under gravitational force, the water goes back to the pump reservoir. The process starts again until all the air in the pump and in the suction line is entirely removed. It is after removing all the air in the pump, when normal pumping process starts.

Figure: Self-priming dirty water pump removing air.

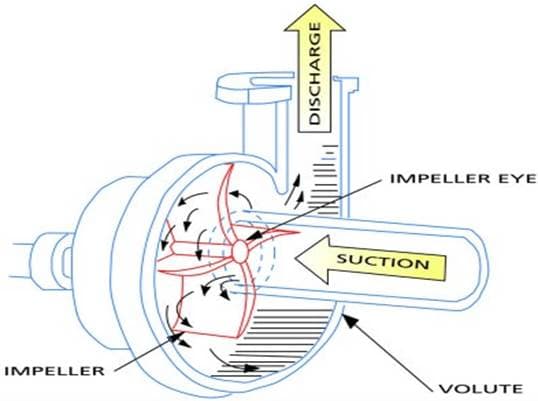

A vacuum facilitates the normal pumping process in the pump. The vacuum occurs due to the pump impeller spinning at high speed. With the vacuum, atmospheric pressure acts on the water in the storage tank, forcing it into the pump via the suction pipe. The water enters the pump through a suction pipe and meets the impeller at its center. With the impeller rotating at high speed, it imparts high velocity into the water, forcing it to move along the flow area on the casing. As it moves along the flow area, the fluid speed reduces while pressure energy increases until the water leaves the pump. The water uses high-pressure energy to move to the required location.

Figure: Working of the pump after priming.

Types of self-priming dirty water pump

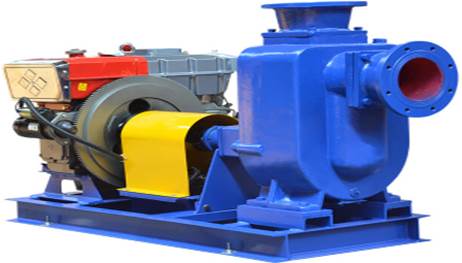

Diesel self-priming dirty water pump

This pump operates on a diesel engine. It is suitable for use in areas far from the source of electricity, making it impossible to use an electric pump. This type of pump is straightforward to use as it only needs to turn on the engine, and the pump starts pumping water. It is highly efficient, making its fluid discharge and head proportional to fuel consumption. Self-priming dirty water pump manufacturers design the pump to be powered using an electric motor when the user finds it necessary. In such cases, it will only need to replace the IC engine with an electric motor.

Figure: Diesel self-priming dirty water pump.

Monoblock self-priming dirty water pump

A Monoblock self-priming dirty water pump is unique in design because the pump and motor are made as one block. As such, only one shaft runs from the motor to the pump without coupling or any other mechanical connecting element. Self-priming dirty water pump manufacturers design this pump for use in areas that need to save on energy costs. This is because the pump helps save on energy since there are no shaft power transmission losses common in pumps that use shaft coupling.

Figure: Monoblock self-priming dirty water pump.

Magnetic drive self-priming dirty water pump

The magnetic drive type of pump uses magnetic technology to run the pump. The pump has two magnets; an outer magnet and an inner magnet. The outer magnet is connected to the motor so that when the motor shaft rotates, it also rotates. The rotation of the external magnet forces the inner magnet to turn due to the magnetic field pattern. Rotating the internal magnet causes the pump impeller to rotate since both magnet and impeller are mounted on the same shaft. This creates a vacuum in the pump, which starts regular water pumping. Magnetic drive self-priming dirty water pumps are also known as sealless pumps since they do not use mechanical seals common in other pumps but instead use the magnet to seal water from leaking. The pumps are highly economical in repair and maintenance since they can serve for seven years without replacing the magnets.

Single-stage self-priming dirty water pump

This is the type of pump that uses one impeller. It is the most common type of water pump since it is cheaper and easy to repair. However, this pump is mostly meant for average flow rates and heads unlike the multistage pumps.

Multistage self-priming dirty water pump

The multistage type of pump uses more than one impeller. The impellers are arranged in series and for each stage, pressure energy increases until the water leaves the pump. As such, the more the pump impellers, the more the hydraulic power; thus, the pump will deliver for a large head. This type of pump is suitable for use in large heads and high flow rates. However, it is hard to repair and clean due to the many impellers. It is also expensive relative to the single-stage pump.

Applications of self-priming dirty water pump

- These pumps are used in transporting sewage in domestic and municipal applications.

- Self-priming dirty water pumps are used in mining applications.

- These pumps are used to transport water for agricultural use.

- They are used in the construction and building industries.

- Self-priming dirty water pumps are used in dewatering to clear floods.

- They are used in the desalination and transportation of fresh and salty water.

- They are used in the manufacturing of paper and pulp.

- They are used in mining industries.

Advantages of self-priming dirty water pump

- These pumps can operate on both dirty and clean water.

- They are capable of priming themselves.

- Self-priming dirty water pumps are easy to repair and clean.

- They are resistant to corrosion.

- These pump have high fluid flow rates.

- They are of various sizes suitable for different heads and flow rates.

- They are versatile as they can be used in various applications.

- Self-priming dirty water pumps are of simple and compact design.

- They produce low noise and vibrations.

- They have smooth flow unlike reciprocating pumps.

- They are highly reliable.

Disadvantages of self-priming dirty water pump

- These pumps are prone to cavitation.

- Self-priming pumps need to be primed after staying without pumping water.

- The pump requires a pump reservoir, which increases its size relative to other pumps.

- These pumps have low efficiency due to large clearance to allow flow of water and solids.

Troubleshooting self-priming dirty water pump

Zero flow rate through the pump

- There is no power on the prime mover. Check that there is power on the motor (electric powered). Also, check all power cables are well connected to ensure power transmission.

- Impeller blockage. Disassemble the pump as instructed by the self-priming dirty water pump manufacturer and clean off any blocking materials.

- Has the pump stayed for a long without pumping water, or is it new? Prime the pump manually.

- Blocked strainer. Check the filter to remove blocking material.

- The suction valve is blocked. Clean clogging material.

- Wrong direction of rotation. Ensure motor direction of rotation matches the arrow indicated on the pump casing.

Bearings overheating

- Misalignment of the shaft. Check if the coupling and shafts are perfectly aligned and realign them properly.

- The bearings covers are excessively tightened. Loosen the covers.

- The bearings are not lubricated. Lubricate the bearings adequately.

The pump produces a lot of noise and vibration

- The pump-foundation connection is loose. Tighten the pump adequately.

- Bearings are worn out. Replace the bearings.

- Partially clogged impeller. Open the pump and clean off clogging materials.

- Misalignment of the shaft. Align the shaft properly.

Summary

Self-priming dirty water pumps are used for pumping clean and dirty water with solid particles. The pump first primes itself before starting regular water transfer. The priming process helps expel air contained in the pump or the suction line. The priming process entails the rotation of the impeller that leads to a vacuum inside the pump. This vacuum draws water into the pump together with the air. The water and air mixture rises the pump to the discharge, but due to the low air density, the air leaves the pump via the discharge port and the water goes back to the pump via gravity. The process repeats several times to ensure all air is expelled, and the actual pumping starts again.

Self-priming dirty water pump manufacturers have produced several pump types, such as single-stage pumps, multistage pumps, magnetic drive pumps, diesel engine pumps, and Monoblock pumps. The advantages of this pump are easy installation and repair, self-priming capabilities, high flow rate, and high reliability, versatility in size, and low noise and vibrations. The pump uses include firefighting, construction, agriculture, desalination, mining, municipal water supply, and dewatering.