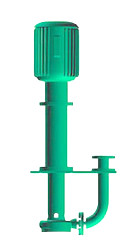

Vertical Cantilever Semi-Open Impeller Pump

What is a vertical cantilever semi-open impeller pump?

A vertical cantilever semi-open impeller is a centrifugal pump containing a semi-open type impeller design supported by a long shaft hanging vertically from the motor and baseplate. The pump’s shaft is anchored at only one end like a cantilever; hence the term cantilever is used in naming the pump. The overhang shaft also rides on heavy-duty bearings located above the pumped fluid. The pump’s semi-open impeller, which features a back wall to strengthen the impeller, enhances the efficiency in handling liquids or products containing suspended solids. In a vertical cantilever semi-open impeller pump, only the impellers, bushings, and casing are submerged in the pumped liquid. It doesn’t have submerged seals, bearings, or suction check valves. Most vertical cantilever semi-open pumps are composed of cast iron to enhance longevity and efficiently dissipate heat to the surrounding liquid. Vertical cantilever semi-open impeller pump manufacturers develop the device to cater to various industrial, residential, and commercial applications.

Figure: Typical cantilever semi-open impeller pump

Components of a vertical cantilever semi-open impeller pump

Electric motor

The electric motor is the source of power for the pump. The vertical cantilever semi-open impeller pump employs an alternating current motor, either a single-phase or a three-phase induction motor.

Pump casing

The pump casing, also called the housing, is the major stationary component of the vertical cantilever semi-open impeller pump, covering the impeller and other internal components. It is usually insulated to protect the electrical and working parts. The vertical cantilever semi-open pump’s casing features a cast iron, ductile cast iron, or stainless-steel construction. The pump casing helps to convert the pumped liquid’s kinetic energy into the pressure head and to direct the flow to the discharge connection

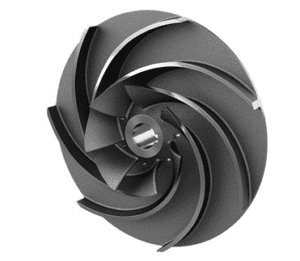

Semi-open impeller

The function of the impeller is to impart kinetic energy to the pumped liquid and move it through the pump body. A semi-open impeller has a back wall that adds mechanical strength to the vanes. It is usually made from cast iron, ductile cast iron, or stainless-steel grades 304 and 316L, depending on the application requirements. Vertical cantilever semi-open impeller pump manufacturers fit the semi-open impeller with delicate clearance between the vanes and the pump casing to avoid slippage and recirculation. Semi-open impellers help to handle liquids or products with suspended solids. However, the semi-open impeller is challenged by reduced hydrodynamic efficiency, but the ability to pass solids is a significant trade-off.

Figure: Configuration of a semi-open impeller.

Pump shaft

The principal function of the pump shaft is to support the impeller. The shaft is a rotary mechanical component riding on bearings and connecting to the motor shaft via a coupling. It is usually made from stainless-steel and cast steel to enhance corrosion resistance and the ability to overcome vibration.

Bearings

Vertical cantilever semi-open impeller pump comprises standard rolling ball anti-friction bearings lubricated by grease or oil. The purpose of the bearings is to hold the shaft and the rotor assembly in place and align them correctly with the fixed ends under the action of radial and axial forces. They also contain the relative motion of the rotor and minimize the friction between the rotating shaft and the stator.

Suction inlet and discharge outlet

The pumped fluid enters the pump through the suction inlet and exists through the discharge outlet, which links with the delivery connections.

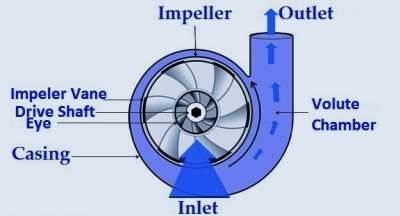

How does a vertical cantilever semi-open impeller pump work?

When the electric motor starts, the mechanical energy output from the motor shaft is transmitted to the impeller via the pump shaft and the coupling. The impeller rotates with the pumped liquid inside the pump casing, creating a vacuum at the impeller’s eye, which allows more pumped liquid to flow into the pump casing. As long as the impeller rotates, more liquid draws into the pump casing, and centrifugal force acting on the impeller blades causes the pumped liquid to move radially outwards, away from the impeller center of rotation, at high tangential velocity. The swirling flow at the exit of the impeller then enters into the diffuser, where the extreme fluid flow speed gradually decreases, leading to the conversion of the high-velocity energy into a high-pressure head. Finally, the pumped liquid discharges from the vertical cantilever semi-open pump at elevated pressure, which allows it to move the liquid to the desired location through the discharge connections.

Figure: Working of a vertical cantilever semi-open impeller pump

Types of vertical cantilever semi-open impeller pumps

Single-stage vertical cantilever semi-open impeller pump

The single-stage vertical cantilever semi-open impeller pump relies on a single impeller to move fluid through the pump. This pump offers the simplest pump design and is less costly to acquire.

Double-stage vertical cantilever semi-open impeller pump

The double-stage vertical cantilever semi-open pump has two impellers for moving fluid through the pump. It provides the performance of two pumps linked in series.

Multistage vertical cantilever semi-open impeller pump

The multistage vertical cantilever semi-open impeller pump contains several impellers to perform a series of pumping stages. The impellers are mounted along the same shaft and housed in different chambers. The multistage design can manage higher fluid pressure than the single-stage or double-stage counterpart. Because the required head per stage is less, the multistage design can operate with minimal leakage.

Applications of vertical cantilever semi-open impeller pumps

Vertical cantilever semi-open impeller pumps are widely used in industrial, residential, and commercial applications. They are found in chemical plants, wastewater treatment facilities, pulp and paper, and power plants. They are used for the following:

- Vertical cantilever semi-open impeller pumps are used for transporting industrial water.

- They are used to transfer and circulate volatile liquids, such as acids and alkalis, in chemical and fertilizer industries.

- They are used for handling clean liquids and liquids containing large suspended solids.

- They are used for moving corrosive and abrasive mixtures.

- They also apply to transport fibrous and non-fibrous slurries containing large solids.

- They are used for moving hazardous fluids and heavy slurries.

- They are used for handling effluents in commercial and industrial premises.

Advantages of a vertical cantilever semi-open impeller pump

- Vertical cantilever semi-open impeller pumps have minimal life cycle cost due to minimal maintenance requirements.

- They have a compact construction, providing ease of installation and handling.

- The vertical cantilever design of the pump is space-saving because the pump takes up less floor space.

- They are highly energy efficient because they use smaller motors and pressure of the surrounding liquid to draw it into the pump.

- They are high reliability in operation.

- The vertical cantilever semi-open impeller pump provides cavitation-free operation because the impeller is submerged, thereby eliminating the spike in pressure as the pumped liquid flows through the pump.

- The pump can run dry.

- The pump is self-priming because the impeller (s) lies in the pumped fluid.

- The pump can pass solid material as it uses a semi-open impeller.

Disadvantages of a vertical cantilever semi-open impeller pump

- Vertical cantilever semi-open pumps are relatively expensive compared to the standard centrifugal pump.

- The pumps have reduced hydraulic efficiency, a common problem associated with using a semi-open impeller.

- They require vertical clearance for installation and maintenance.

- Vertical cantilever semi-open pumps experience mechanical seal issues.

- Mechanical seals may fail or dry out due to infiltration and accumulation of gases in the seal chamber. Leakage in the mechanical seals can damage the motor.

Troubleshooting a vertical cantilever semi-open impeller pump

The inline pump doesn’t give discharge after startup

- The suction lift is too high. Raise the liquid level in the suction tank or lower the vertical cantilever semi-open impeller pump to reduce the static charge.

- The pump inlet is blocked. Clear the inlet of any obstruction.

- The inline pump operation is reversed. Check that the direction of the motor rotation matches the direction of the vertical cantilever semi-open impeller pump manufacturer’s arrow indicated on the pump casing. Reverse the motor polarities.

- There is air in the pump or suction pipework. Fill the pump or pipework with water to drive out the air from the pump system. Remember, the vertical cantilever semi-open impeller pump cannot prime with air on the suction side.

- The impeller, filter, or check valves are clogged. Inspect and clean any blockage in the valves.

- There is an insufficient monomeric head due to high friction losses exceeding the pump design. Raise the pump power to the level recommended by the vertical cantilever semi-open impeller pump manufacturer. Ensure that the delivery pipes have the correct diameters. Be sure to open all the valves.

Pump operation is noisy

- The bearings are excessively worn-out. Inspect the conditions of the bearings on the rotor assembly or inside the motor and replace them if necessary.

- The vertical cantilever semi-open impeller pump is working in cavitation. Ensure that the net suction pressure head meets the vertical cantilever semi-open impeller pump manufacturer’s specifications. Make sure that all the suction line valves are fully open.

- The pump is working outside the design duty range. Ensure the pump is working within the duty range recommended by the vertical cantilever semi-open impeller pump manufacturer.

- There is entrained air in the fluid. Ensure the vertical cantilever semi-open impeller pump is sufficiently submerged to prevent vortex formation on the fluid’s surface.

The pump is vibrating excessively

- Some of the vertical cantilever semi-open impeller pump’ components are unbalanced. Inspect and rebalance elements if it is necessary.

- The impeller is severely worn out or defective. Inspect and replace the impeller with another one from the vertical cantilever semi-open impeller pump manufacturer if need be.

- The pump shaft is oblique or unbalanced. Inspect the shaft, rebalance it as required, or replace it.

The pump driver is overloaded

- The vertical cantilever semi-open impeller pump’s speed is too high. Lower the pump speed.

- There is a significant coupling misalignment. Inspect coupling and realign pump and motor.

- The density and viscosity of the liquid exceed the pump design. Ensure that the vertical cantilever semi-open impeller pump matches the application.

- The motor is defective. Inspect the engine for defects such as poor ventilation, location, and repair or replace the motor and correct or replace the motor.

- There is mechanical friction within the pump. Inspect the pump assembly for any obstruction or deflection.

- Packings wound too tightly. Inspect and loosen nuts on packing glands as necessary.

Bearing overheating

- The bearing covers are too tight. Loosen the bearing covers.

- The coupling alignment is poor. Inspect and align the coupling correctly.

- There is excessive grease in the bearing housing. Drain the excess grease. Maintain the oil at the level recommended by the vertical cantilever semi-open impeller pump manufacturers.

- The lubricating oil is insufficient or contaminated with dirt. Check that the pump’s level of oil or grease is in line with the vertical cantilever semi-open impeller pump manufacturer’s specifications. Ensure that the bearing housing is clean before lubricating.

Summary

A vertical cantilever semi-open impeller pump contains a semi-open impeller supported on a vertical shaft which is anchored at only one end of the motor and baseplate like a cantilever. The overhang shaft rides on heavy-duty rolling ball bearings above the pumped fluid. The pump’s semi-open impeller features a back wall to strengthen the vanes. Vertical cantilever semi-open impeller pump manufacturers use a semi-open impeller because it helps to enhance the pump’s efficiency in handling liquids or products containing suspended solids.

Most vertical cantilever semi-open impeller pumps are composed of cast iron to enhance longevity and heat dissipation. They are available in different designs and with single-phase or three-phase induction motors to meet various application requirements. These devices cater excellently to a broad scope of industrial, residential, and commercial applications. Typical uses of vertical cantilever semi-open impeller pumps include transporting industrial water and circulating volatile liquids in chemical industries. Vertical cantilever semi-open impeller pumps have minimal life cycle cost and unbeaten energy efficiency and reliability.