Electric Water Transfer Pump

What is an electric water transfer pump?

An electric water transfer pump is a mechanical device designed to move clean water close to its source. It works by increasing the pressure of water in order to move it from one place to another. Most electric water transfer pumps are centrifugal pump types with a closed vane impeller and powered using an electric motor. In areas where floods cause an overflow, the electric water transfer pump is ideal for draining as much water as possible. It also suits lawn and garden watering, pond or pool filling, and sprinkler systems. Electric water transfer pump manufacturers develop these edge-cutting units to provide attractive performance metrics, such as a maximum pressure head of 115 feet and a maximum vertical suction lift of 28 feet. Because of the closed vane impeller, the electric water transfer pump can efficiently generate pressure and fluid flow rates. However, debris can easily wedge between the front and back shrouds of the impeller.

Figure: Showing the configuration of an electric water transfer pump

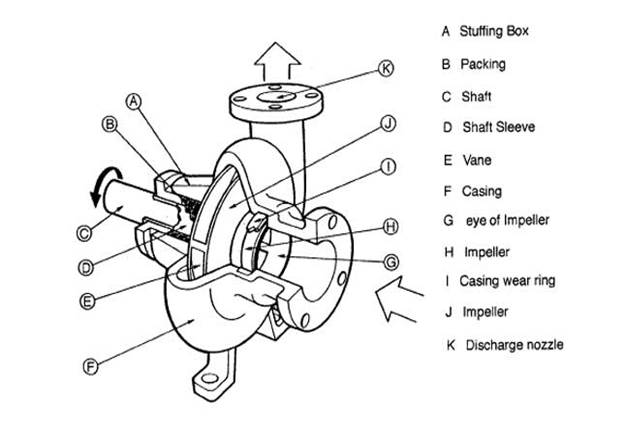

Components of an electric water transfer pump

Figure: Components of an electric water transfer pump.

Electric motor

The electric motor is the source of the mechanical power to run the pump. The primary function of the electric motor is to provide mechanical energy for rotating the pump impeller. The electric motor is close-coupled to the pump using a shaft and coupling.

Pump casing

The pump casing houses the pump’s internal components and helps to convert the high kinetic energy of water into a pressure head. The pump casing is usually equipped with a sealing ring to prevent water leakage and to contain pressure during the pumping operation. Electric water transfer pump manufacturers create the pump casings from various materials, such as cast steel, ductile cast iron, or stainless steel.

Shaft

The shaft is a rotary mechanical component centrally located in the pump and riding on bearings. It supports the impeller and connects the pump rotor assembly to the motor through coupling.

Impeller

The impeller increases the kinetic energy and pressure of the fluid to move through the pump. It comprises a series of backward curved vanes and can be either an open-type impeller or a radial flow closed-type impeller. The electric water pump manufacturers employ a closed vane impeller because it is more robust and can efficiently generate high pressure and flow rate.

The rotor assembly

The rotors assembly comprises the shaft, impeller, shaft sleeves, bearings, and coupling. The bearing suspension supports the rotor assembly while the coupling connects it to the drive shaft.

Suction and discharge nozzles

The suction nozzle connects to the pump inlet, allowing water to flow into the pump casing, while the discharge nozzle links with the outlet port to allow water to flow out of the pump to the designated location.

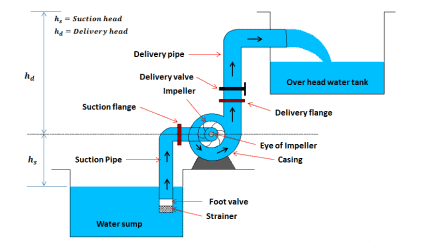

How does an electric water transfer pump work?

An electric water transfer pump operates by converting the mechanical energy of an impeller into kinetic energy and then the pressure energy of water. When the electric motor starts, the mechanical torque is transferred to the impeller via the pump shaft and the coupling. The impeller rotation creates a vacuum inside the pump, allowing the water to flow into the pump casing under the external atmospheric pressure. Once the water strikes the impeller, the centrifugal force acting on the impeller blades moves it radially outwards, away from the impeller’s eye, at a high tangential velocity. The swirling flow at the exit of the impeller then enters into the volute chamber, where the extreme fluid flow speed decreases due to the gradually expanding flow path, and the high-velocity energy converts into a high-pressure head. The water under pressure then discharges from the electric water transfer pump and enters the delivery pipe to transport it to the desired location.

Figure: Working of an electric water transfer pump

Types of electric water transfer pumps

End suction electric water transfer pump

The end suction electric water transfer pump consists of an axial suction and the discharge at 90 degrees to the suction. It can be long coupled with a separate pump and motor shaft or close coupled (where the motor is in the same unit with the pump), often referred to as a Monobloc. In a larger end-suction pump electric water transfer pump, the pump casing consists of a dual volute to reduce the forces acting on the impeller, motor, shaft, and bearings. The end-suction water transfer pump can be either frame mounted or a close-coupled end-suction pump. Generally, end-suction water transfer pumps are simple, reliable, and have low initial acquisition and installation costs.

Figure: End-suction electric water transfer pump.

Inline electric water transfer pump

An inline electric water transfer pump consists of the suction and discharge ports oriented straight to the piping system, i.e., the centerline of the pump’s inlet and outlet is on the same level. The inline design facilitates a smooth flow of water through the pump system. It is usually designed for vertical or horizontal installations. An everyday use of the inline electric water transfer pump is to remove liquids from decontamination showers.

Figure: Inline electric water transfer pump.

Self-priming electric water transfer pump

This is a type of pump which is capable of priming itself. The priming process involves filling the pump with water to help expel air in the suction line and inside the pump. With the air in the pump, atmospheric pressure is not able to pull water from its source into the pump. Electric water transfer pump manufacturers design this pump such that when the pump is started, impellers create a vacuum in the pump. This vacuum forces the air mixture upwards towards the discharge. Due to low density, air is expelled via the discharge while water goes back to pump reservoir via gravity. The process repeats several times until all the air is removed from the pump after which normal pumping starts. Self-priming electric water transfer pumps help relive you of priming process.

Figure: Self-priming electric water transfer pump.

Applications of an electric water transfer pump

These pumps are evident in urban water supply, civil engineering, construction system, agricultural water conservancy system, power station system, ship systems, etc. common uses of the electric water transfer pump include the following:

- Electric water pumps are used for draining flood water.

- They are used to fill ponds or pools.

- They are used for lawn and garden watering.

- They are used to supply water to sprinkler systems and other irrigation applications.

- They also apply to power plant water supply and drainage.

- Electric water transfer pumps are also used to move water from a dam or a domestic well directly to storage tanks or for other purposes.

- They are used for dewatering and constriction-related uses.

Advantages of electric water transfer pump

- They have high efficiency and low noise.

- They are of simple structure and compact design.

- They have a strong motor and good body design.

- The wetted components are specially designed to resist not only corrosion but also present good wear resistance.

- They have low power consumption, helping with energy conservation.

- They are cheap and easy to acquire.

- They have low Life Cycle Costs due to minimal maintenance requirements.

- The pump can handle a wide range of pressure and flow rates.

- They provide a continuous and steady water flow output.

- They are easy to install, clean and repair.

Disadvantages of electric water transfer pump

- An electric water transfer pump is unfit for dirty water or solid particles since debris can easily wedge between the front and back shrouds of the impeller.

- They are challenging to clean if they become clogged.

- The pump can fail under extreme loading conditions.

Troubleshooting an electric water transfer pump

The pump does not start

- There is a fault in the pump wiring, e.g., loose connections or broken wiring. Inspect and fix loose connections or replace the damaged wires.

- The voltage is irregular due to dirt or corrosion at the pressure switch. Inspect the pressure switch and clean it of any debris or pollution.

- The fuse receptacles are dirty or corroded. Inspect and clean fuse receptacles if necessary.

- The circuit breaker is open, or the fuse is blown-out. Inspect the electric water transfer pump for a blown-out fuse and replace it if necessary. Shut the circuit breaker.

- The power supply to the panel is insufficient. Ensure that the voltage and current supply to the pump match the amount specified in the electric water transfer pump manufacturer’s manual.

The pump overheats and shuts off

- The motor voltage does not match the line supply voltage. Check the motor supply voltage against the voltage specified by the electric water transfer pump manufacturer on the nameplate.

- The motor has the wrong wire sizes. Consult the national electrical codes for a helpful guide on the correct wire sizes and circuit protection devices.

- The impeller collides with the pump casing or lacks a free rotation. Disassemble the pump and align the impeller correctly.

- There is too much thrust due to mechanical failure inside the pump. Inspect the pump assembly and correct any shortcomings.

- The pump bearings are worn-out. Inspect and replace the bearings if necessary.

- The pump is operating at a low capacity. Ensure the pump runs at the rated duty according to the electric water transfer pump manufacturer’s guide.

The noise level is too high

- There are foreign materials present in the electric water transfer pump. Dismount and clean the pump inside.

- The impeller is severely damaged or worn out. Inspect and replace the impeller.

- The pump is working outside the duty range. Ensure the pump’s duty range is correct following the electric water transfer pump manufacturer’s manual.

- The electric water transfer pump is working in cavitation. Check that the suction line valves are fully open.

The pump is experiencing excessive vibration

- The pump impeller is partially clogged. Inspect and clean the impeller.

- The mounting plate and the foundation lack sufficient rigidity. Reinforce the foundation, and mount the electric water transfer pump tightly.

- Some pump parts are loosely held within the pump body. Tighten any loose parts to the torque level recommended by the electric water transfer pump manufacturer.

- The pump shaft is oblique. Check the shaft, rebalance it as required, or replace it.

- Some pump components are unbalanced. Inspect and rebalance the parts if necessary.

The pump driver is overloaded

- The motor has shortcomings, such as poor ventilation, wrong positioning, etc. Inspect the electric motor and do necessary repairs.

- The pump speed is too high. Reduce the pump’s rotational speed to match the electric water transfer pump manufacturer’s specification.

- Mechanical friction within the pump. Repair any obstruction or deflection.

- Fluid density or viscosity is too high. Make sure that the pump matches the application.

- The packing wound is fixed too tightly. Loosen nuts on packing glands to the electric water transfer pump manufacturer’s recommended torque level.

Summary

An electric water transfer pump is a centrifugal pump with a closed vane impeller that uses an electric motor to move clean water close to its source. The pump’s working process entails increasing the water pressure to move it from one place to another. The closed vane impeller design allows the electric water transfer pump to efficiently generate high pressure and fluid flow rate. Electric water transfer pumps have different uses in urban water supply, civil engineering, construction, agricultural water conservancy, power station, ship systems, etc. The electric water transfer pump manufacturers avail the devices in various designs, such as end-suction electric water transfer pumps, inline electric water transfer pumps, and self-priming electric water transfer pumps. Electric water transfer pumps offer numerous benefits, including excellent performance, high efficiency, and low noise. They also have a compact structure that is simple to set up/assemble and easy to repair.