Vertical Cantilever Sump Submersible Pump

What is a vertical cantilever sump submersible pump?

A vertical cantilever sump submersible pump is a type of centrifugal pump with a long shaft that is immersed in the pumped liquid during operation. In a vertical cantilever sump submersible pump, the impeller is anchored vertically at one end and hanging from the motor and baseplate; hence the term cantilever is used. The pump’s motor is supported on the upper part of the baseplate and is air-cooled while all other components are mounted below the baseplate. The pump’s overhang shaft is supported by heavy-duty bearings that are located above the liquid surface. However, for a vertical cantilever sump submersible pump only the impeller(s), bushings, and casing are submerged in the sump liquid. The vertical cantilever design eliminates the need for submerged seals, bearings, or suction check valves and the maintenance challenges linked with these additional components. Vertical cantilever sump submersible pumps are used in applications where the pumped liquid’s temperature is above 40 degrees Celsius and the submersible electric motor cannot be effectively cooled.

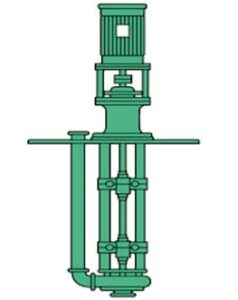

Figure: showing the configuration of a vertical cantilever sump submersible pump

Components of a vertical cantilever sump submersible pump

Casing

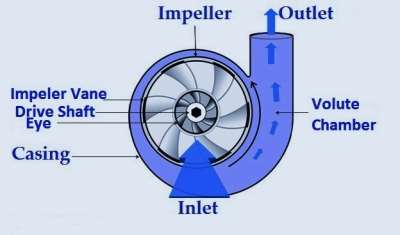

The pump casing is a narrow air- passage surrounding the impeller. The casing acts as a pressure containment vessel and has suction and discharge ports. It also converts the fluid kinetic energy into a pressure head and directs the flow out of the pump through the delivery pipe. Vertical cantilever sump submersible pump manufacturers use cast iron for the pump casing because it easily dissipates heat to the surrounding fluid. Stainless steel and alloy steel materials are also employed when the pump is for use with corrosive liquids.

Impeller

The impeller is the part of the rotor assembly consisting of a series of backward curved blades or vanes. The main function of the impeller is to increase the kinetic energy and pressure of the fluid. It is usually mounted on the pump shaft and housed in a watertight casing.

Shaft

The shaft is a rotary mechanical component riding on bearings and connecting to the prime mover via coupling. Its main function is to support the impeller.

Bearings

The main function of the bearings is to hold the shaft and the rotor assembly in place and align them correctly with the fixed ends under the action of radial and axial forces. They also help to contain the relative motion of the rotor and minimize the friction between the rotating shaft and the stator. Vertical cantilever sump submersible pumps are fitted with standard ball-type anti-friction bearings lubricated by grease or oil.

Pump inlet

The pump inlet is the point where the pumped liquid enters the pump casing. It is the point of lowest pressure in any given pump. The lower end of the suction pipe is fitted with a filter to prevent foreign bodies from entering the pipe.

Delivery Pipe

The main purpose of the suction pipe is to connect the pump casing to the outlet source. The pumped fluid is transported to the required location through this pipe.

How does a vertical cantilever sump submersible pump work?

When the electric motor is started, electrical energy supplied to it is converted into mechanical energy, which is then transmitted to the pump rotor via the coupling and pump shaft. As the rotor turns, the impeller blades impart great kinetic energy to the pumped medium. As long as the impeller rotates more liquid draws into the pump casing and centrifugal force acting on the impeller causes the liquid to move radially outwards at high tangential velocity, away from the impeller center of rotation. The swirling flow at the exit of the impeller is then directed into the diffuser where the extreme fluid flow speed gradually decreases, leading to the conversion of the high-velocity energy into a high-pressure head. This elevated exit pressure, allows the vertical cantilever sump submersible pump to push the liquid to the surface and move it to the designated location via the delivery pipe.

Figure: Working of a vertical cantilever sump submersible pump

Types of vertical cantilever sump submersible pumps

Single-stage vertical cantilever sump submersible pump

The single-stage type of vertical cantilever sump submersible pump has one impeller to impart motion to the fluid. This is the simplest design of the pump and is less costly to acquire.

Figure: showing the configuration of a single-stage vertical cantilever sump submersible pump.

Double-stage vertical cantilever sump submersible pump

The double-stage vertical cantilever sump submersible pump has two impellers for moving fluid through the pump, and it performs like two pumps linked in a series.

Multiple-stage vertical cantilever sump submersible pump

The multistage kind of vertical cantilever sump submersible pump has more than one impeller, providing the functionality of several pumps arranged in series. The multistage design can pump fluid to a higher pressure than the single-stage or double-stage counterpart. It also has minimal leakage because the pressure head per stage is less.

Vertical cantilever sump submersible pump with submerged bearings

In this type of vertical cantilever sump submersible pump, the pump bearings are located below the surface of the pumped liquid. The submerged bearing assembly’s split sleeves are clamped across the pump’s column using through bolts. These bolts allow easier pump disassembly and maintenance.

Figure: showing the configuration of a vertical cantilever sump submersible pump with submerged bearings.

Applications of a vertical cantilever sump submersible pump

A vertical cantilever sump submersible pump excellently caters to all applications involving the passing and processing of clean or contaminated liquids, or slurries. The vertical cantilever sump submersible pump manufacturers equip the unit with great adaptability through a wide range of designs to suit many sump pump applications. They can be found in chemical plants, wastewater treatment facilities, pulp and paper making, power plants, etc. Vertical cantilever sump submersible pumps find the following uses:

- Vertical cantilever sump submersible pumps are used for pumping industrial wastewater

- They are used for transferring effluent from commercial premises

- They are used for handling corrosive and abrasive liquids

- They are used for transporting abrasive fibrous slurries or non-fibrous slurries containing large solids

- They are also used for handling heavy slurries with up to 70% solids

Advantages of a vertical cantilever sump submersible pump

- A vertical cantilever sump submersible pump has a simple and robust design with ease of maintenance.

- The pump has minimal life cycle cost because of the exceptionally low maintenance requirements.

- The pump can run dry without damage.

- It is high reliability in operation.

- The pump is self-primming because the liquid level is normally above the volute

- The vertical cantilever sump submersible pump is cavitation free because there is no spike in pressure as the pumped liquid flows through the pump.

- The pump is highly energy efficient because it doesn’t require energy to suck fluid into the pump casing.

- The vertical cantilever design of the pump is space-saving.

Disadvantages of a vertical cantilever sump submersible pump

- Since the vertical cantilever sump submersible pump is submerged, the maintenance personnel can’t observe the pump components during operation. This makes the diagnosis and repair of pump failure a bit difficult.

- The pump is subject to undetectable wear and tear in the submerged conditions, which may result in pump leakage or failure.

- The pump is more expensive than non-submersible pumps.

- A crane is required to uninstall the pump and the pump must be transported to a local repair facility for inspection and repair due to the absence of a structure on the surface.

Troubleshooting a vertical cantilever sump submersible pump

The pump won’t start

- There is a blown fuse or tripped circuit breaker. Inspect the vertical cantilever sump submersible pump for a blown-out fuse and replace it if necessary. Reset the circuit breaker if it is tripped.

- Dirty or corroded fuse receptacles. Check and clean fuse receptacles as necessary.

- The voltage is irregular due to dirt or corrosion at the pressure switch. Inspect the pressure switch and clean it of any debris or pollution.

The pump discharge is insufficient

- The pump isn’t fully submerged. Make sure that the vertical cantilever sump submersible pump is immersed the in the pumped medium as required.

- The check is wrongly installed or defective. Inspect the check valve, correct its position or replace it if necessary.

- The pump’s operation is reversed. Reverse the motor polarities. Make sure the motor’s rotation direction matches the direction indicated by the vertical cantilever sump submersible pump manufacturer on the pump casing.

- The pump is air bound. Ensure that the vertical cantilever sump submersible pump system is free of air.

- Clogged impeller. Inspect the impeller and remove any clogging material.

Pump operation is noisy

- Excessive wear of bearings. Inspect the conditions of the bearings on the rotor assembly or inside the motor and replace them if necessary.

- There is air in the fluid. Ensure the vertical cantilever sump submersible pump is adequately submerged to prevent vortex formation on the fluid’s surface.

- The vertical cantilever sump submersible pump is working in cavitation. Ensure that the net suction pressure head isn’t too low and is per the pump manufacturer’s specifications. Ensure that the suction line valves are fully open.

- The pump is working outside the design duty range. Ensure the pump is working within the duty range recommended by the vertical cantilever sump submersible pump manufacturer.

The pump is vibrating excessively

- Some of the vertical cantilever sump submersible pump’ components are unbalanced. Inspect and rebalance components if it is necessary.

- Oblique or unbalanced shaft. Inspect the shaft and replace or balance it as required.

- The impeller is severely worn out or defective. Inspect and replace the impeller with another one from the vertical cantilever sump submersible pump manufacturer if necessary.

The overload protector trips too often

- Incorrect voltage. Use a voltameter across the line terminals to determine if the pump is getting the voltage designed by the vertical cantilever sump submersible pump manufacturer.

- The protector is in direct sunlight. Shade or ventilate the box.

- The stop switch level is set too low. Raise the stop switch to the level recommended by the vertical cantilever sump submersible pump manufacturer.

- The liquid density or viscosity is too high. Ensure that the vertical cantilever sump submersible pump is suitable for the application.

The motor overheats

- There is a voltage surge and spike due to a storm or lightning strike. Fit the vertical cantilever sump submersible pump with external surge protection.

- The pump is not fully submerged in operation. Make sure the submersible pump part is fully submerged.

- The motor is poorly wired. Consult a licensed electrical technician to inspect the motor wiring and correct any shortcomings.

- The motor is operating outside its design limits. Make sure the motor is used within the design limits specified by the pump manufacturers.

- Use of wrong lubricants. Make sure the lubricant is right for the vertical cantilever sump submersible pump.

- The vertical cantilever sump submersible pump is overloaded. Make sure the motor receives the correct amount of current and voltage.

Summary

A vertical cantilever sump submersible pump is a type of centrifugal pump containing an overhang shaft and a pump head that is anchored vertically at one end and hanging from the motor and baseplate. The pump is designed to operate below the surface of the pumped liquid. In a vertical cantilever sump submersible pump, the motor and bearings are mounted on the upper side of the base plate and remain above the pumped fluid, while the pump impeller(s), bushings, and casing are submerged in the sump liquid. Vertical cantilever sump submersible pumps are perfect for all applications involving the passing and processing of clean or contaminated liquids, or slurries. The vertical cantilever sump submersible pump manufacturers provide the units with great adaptability through a wide range of designs to fit various applications in many industries, such as chemical plants, power plants, etc. Vertical cantilever submersible pumps are self-priming, robust in construction, easy to maintain, and very reliable.