End Suction Pump

What is an end suction pump?

An end suction pump is a common class of centrifugal pump where the suction is axial, and the discharge is 90 degrees to the suction. It is usually mounted in the horizontal position and driven through mechanical means such as an electric motor or engine. The electric drive motor shaft can be long-couped or close-coupled to the pump head. Most end suction pumps also feature a back pull-out design with a spacer coupling to allow easy pump maintenance and repair without interfering with the motor alignment. The back pull-out configuration eliminates the need for motor alignment and saves installation space. End suction pump manufacturers create more extensive units with a dual volute casing to minimize the forces acting on the impeller, motor, shaft, and bearings. End suction pumps are available in single-stage and multistage versions and with different construction materials such as cast iron, bronze, and stainless steel. Generally, end suction pumps have relatively simple engineering and low cost.

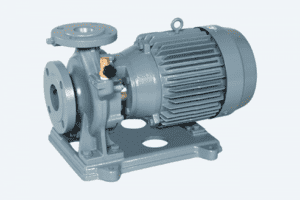

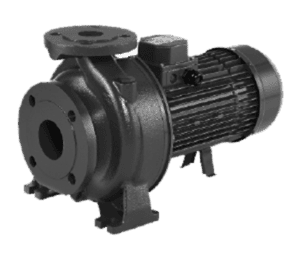

Figure: Showing the configuration of an end suction pump

Components of an end suction pump

Electric motor

The motor is the source of the mechanical power to run the pump. It receives an electric power supply and converts it into mechanical torque to rotate the impeller. The type of electric motor can be either a single-phase AC or a three-phase AC induction motor.

Pump casing

The pump casing houses the impeller and the intake and discharge ports. It also contains the volute chamber, which helps to convert the kinetic energy into the pressure head. In larger end-suction pumps, the pump casing is usually of the dual volute type to reduce the forces acting on the impeller, motor, shaft, and bearings.

Impeller

The impeller is a rotary component designed with a series of vanes or blades that help to displace water through the pump. As the impeller rotates, the blades impart kinetic energy and velocity to the pumped fluid, enabling it to move through the pumping systems. End suction pumps use a type of impeller known as a closed single-suction impeller. It features support walls on either side of the blades and a single impeller eye to allow the pumped fluid to enter from one side only.

Shaft

The end suction pump manufacturers mainly develop the pump shaft from stainless steel material because it has excellent corrosion resistance. The is a rotary solid component located at the center of the pump shaft and supported on bearings, one on each end. It transfers mechanical torque from the motor drive shaft to the impeller during pumping.

Bearings

The end suction pump employs ball-type bearings located within a bearing housing. The bearings carry the shaft and the impeller, ensuring the correct alignment with the fixed ends under the axial and radial forces.

Coupling

A coupling is a device that connects the pump shaft and the motor shaft. It has two main designs, which are close coupling and long coupling. The impeller is directly mounted on the motor shaft in a close coupling. The long coupling features a separate motor and pump shaft and is further divided into the flexible or rigid coupling. A flexible coupling accommodates minor shaft misalignment. The rigid coupling, however, cannot tolerate any shaft misalignments, thus requiring precise angular and lateral alignment.

Suction port and discharge port

The suction port is the intake manifold connecting with the inlet nozzle to allow the pumping fluid to enter the casing. The liquid exits the pump through the discharge port, which links with the delivery nozzle or the discharge connections.

How does an end suction pump work?

When the motor starts, the pump shaft rotates the impeller at the motor RPM. As the impeller rotates, it displaces the priming liquid inside the pump casing, creating a vacuum in the impeller’s eye. Due to the atmospheric pressure outside the pump, more pumped fluid is forced into the pump through the suction inlet and toward the impeller’s eye to fill the void. So long as the impeller rotates, the liquid will be continuously drawn into the pump casing to be pumped. Once the pumped liquid enters the impeller, the centrifugal force acting on the impeller blades pushes it from the center of the impeller to the outer edges and into the volute casing at extremely high tangential velocity. The fluid velocity decreases in the volute chamber due to the gradually expanding flow path, and some of the kinetic energy is converted into static pressure energy. Finally, the liquid enters the discharge pipe perpendicularly to the suction line and at very high pressure, allowing it to flow to the required destination.

Types of end suction pumps

Single-stage end suction pump

The single-stage end suction pump is the most common variant of the end suction pump. It consists of one impeller in the pump casing to increase the flow velocity and pressure to move through the pump. It presents the most uncomplicated design of the end suction pump with many associated benefits such as portability, low cost, and ease of installation and maintenance. It is used in most water supply systems and industrial applications to boost water pressure.

Figure: Showing the configuration of a single-stage end suction pump.

Multistage end suction pump

A multistage end suction pump comprises several impellers mounted in series along the same pump shaft and housed in different chambers to help pressurize the pumped liquid in stages. The pumped liquid enters the first stage impeller at the suction pressure and discharges from the last impeller at elevated pressure. The multistage end suction pump can manage higher fluid pressure and flow rates than its single-stage counterpart.

Figure: Showing the configuration of a multistage end suction pump.

Close-coupled end suction pump

In a close-coupled end suction pump, the impeller is attached to the end of the motor shaft, and the pump casing bolts directly to the face of the motor. It is also known as a monobloc end suction pump. The end suction pump manufacturers mainly employ the close-coupled design for single-stage pumps. It is preferred for many industrial and domestic water supply systems because the close coupling eliminates the need for pump alignment in the field, saving installation and maintenance time.

Figure: Showing the configuration of a close-coupled end suction pump.

Long-coupled end suction pump

A long-coupled end suction pump has separate motor and pump shafts that join together via a long coupling. The long coupling design allows for faster disassembly and maintenance without interfering with the motor alignment. It also provides an adequate space between the pump and motor to prevent fluid ingress into the motor in case of seal failure. Unlike the close-coupled design, the long-coupled design applies to single-stage and multistage versions of the end suction pump.

Figure: Showing the configuration of a long-coupled end suction pump.

Applications of end suction pump

The end suction pump manufacturers develop the devices to perform excellently in residential and industrial water supply systems, agricultural /irrigation applications, and HVAC systems for heating, ventilation, and air-conditioning. They are used for the following.

- End suction pumps supply clean water for residential, municipal, and commercial uses.

- They are used to supply water irrigation water to sprinklers in agricultural farms.

- They are used for condensate handling and refrigeration and cooling tower installations.

- They circulate hot, cold, or cooing water in air conditioning systems.

- They are used for handling clean or dirty liquid with low viscosity and similar properties to water.

- They are used to support firefighting equipment.

- They are used as pressure-boosting pumps in plumbing systems for large buildings such as big-box stores, stadiums, office buildings, and shopping malls.

Advantages of end suction pump

- End suction pumps have a compact design that is easy to install and operate.

- They have high flow rate capabilities.

- They have few moving parts and occupy very little space.

- The end suction pump provides a steady and consistent output.

- They can withstand high system pressure and temperature.

- They are perfect for a wide variety of clean and dirty liquids with low viscosity and similar properties to water.

- They have high hydrodynamic efficiency and energy efficiency.

- They provide a wide range of flow rates to suit different application demands.

- They have a solid mounting base that eliminates vibration effects and enhances the pump’s reliability.

Disadvantages of end suction pump

- End suction pumps are not self-priming and must always be manually filled with the necessary liquid volume to start the pumping operation.

- They are subject to cavitation, which may corrode the impeller and the casing.

- They are subject to seal failure, which can cause damage to the motor.

Troubleshooting an end suction pump

The motor overheats and shuts off

- Mismatch of the motor voltage and the line supply voltage. Check the motor supply voltage against the specification on the nameplate and adjust accordingly.

- The impeller collides with the pump casing. Dismantle the pump, align the impeller, or replace it.

- Use of wire of wrong sizes. Make sure the wires in use satisfy the national electrical codes and the standards for circuit protection devices.

The pump gives zero flow after the startup

- The pump is operating in reverse. Interchange the motor polarities. Check that the motor rotation direction matches the direction shown in the end suction pump manufacturer’s manual or the movement indicated using an arrow on the pump casing.

- The suction lift is too high. Lower the pump or raise the liquid level in the tank.

- The manometric head is insufficient. Ensure all valves are open and the pipe diameter of the pipes meets the sizes set by the end suction pump manufacturers.

- The impeller or check valve is clogged. Inspect the impeller and check valves, and clear any blockage.

The pump’s flow rate is unstable

- The pump lifts liquid with air. Check the depth of the suction pipework or valve in liquid and deepen if required.

- The pump lifts liquid with air. Check the depth of the suction pipework or valve in liquid and deepen if required.

- The bottom valve is leaking. Inspect the bottom valve for leakage and correct it.

- The voltage is too low, leading to a decrease in pump speed. Check the power supply voltage and adjust it as necessary.

The pump vibrates excessively, or it is noisy

- The impeller is severely worn out. Inspect and replace the impeller with another from the end suction pump manufacturers. Ensure all valves are open and pipe diameters are correct.

- There are unbalanced components in the pump. Inspect and rebalance the end suction pump components as necessary.

- Some parts are loosely tightened. Tighten the pump components to the torque level recommended by the end suction pump manufacturers.

- The pump shaft is oblique or unbalanced. Inspect the post, rebalance it as required, or replace it.

- Some pump components are excessively worn-out. Inspect the rotor assembly for worn-out bearings or impellers and replace them if necessary.

Summary

An end suction pump is a centrifugal pump with axial suction and the discharge at 90 degrees to the suction. It is usually designed for horizontal installations and operates using an electric motor or engine. The electric drive motor shaft can be long-couped or close-coupled to the pump head. The end suction pump manufacturers also develop the devices with a back pull-out design to facilitate easy pump maintenance and repair without disturbing the motor alignment. The larger units of end suction pumps contain a dual volute casing, which helps to reduce the forces acting on the rotor. End suction pumps are available in different designs and construction materials to suit various applications. They are used to supply clean water in residential and commercial buildings, agricultural or irrigation farmlands, and to boost water pressure in industrial applications. Significant benefits of end suction pumps include high flow capabilities, efficiency, and compact engineering that is easy to install, operate and maintain.