Stainless Steel Submersible Pump

What is a stainless-steel submersible pump?

A stainless-steel submersible pump is made of stainless steel and is designed to operate below the surface of the pumped liquid. All the pump components that come into contact with the liquid are made from stainless steel. The stainless-steel submersible pump manufacturers design the edge-cutting units mainly for handling clean, clouded, or slightly contaminated water, such as swimming pool water, groundwater, rainwater, etc. However, the use of corrosion-resistant material combined with food-grade lubricant also makes the stainless-steel submersible pump suitable for food and mild chemical industries. The stainless-steel submersible pump provides great performance parameters, including a maximum flow rate of 21. 50 cubic meters per hour, a maximum total head of 19 meters, and motor output of 1.5 kilowatts. The stainless-steel submersible pumps are available with single-phase and three-phase motors with or without float switches. Stainless steel submersible pump manufacturers tailor the units to meet most domestic and industrial pumping systems requirements while offering unbeaten efficiency and reliability.

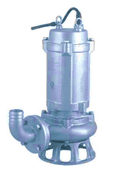

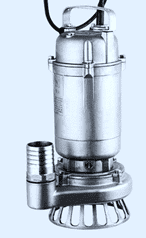

Figure: Showing the configuration of a stainless-steel submersible pump

Components of a stainless-steel submersible pump

pump casing

The pump casing, also called the housing, is the major stationary component of the stainless-steel submersible pump. The stainless-steel submersible pump’s casing is usually manufactured from cast stainless steel and insulated to protect the electrical and working parts. The pump housing contains the impeller and other internal components of the pump. Its main function is to convert the pumped liquid’s kinetic energy into the pressure head and to direct the flow to the discharge connection. Stainless-steel submersible pump manufacturers usually split the casing in the horizontal plane for easier dismantling and removal of the entire impeller. The two halves are connected using bolts and location pins. Generally, the pump casing can be either a diffusing or volute casing. A diffusing casing is circular and contains several guide vanes, surrounding the impeller in the pump assembly. On the other hand, the volute casing features a spiral design in which the passage of the liquid increases gradually all around the casing’s circumference.

Motor

The motor is the source of power for the pump. The motor is also hermetically sealed to keep the pumped fluid from entering the motor, which could cause damage. Motors are broadly classified as AC or DC motors. AC motors operate using alternating current while Dc motors use direct current. Stainless steel submersible pumps are designed to work with the AC type of motor, which can be either a single-phase induction motor or a three-phase induction motor. These kinds of motors are designed to operate at a wide range of currents and voltages.

Impeller

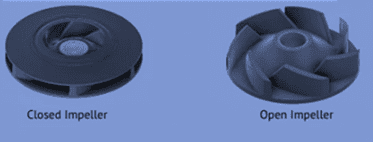

The impeller is the main rotating part of the stainless-steel submersible pump. Its main purpose is to provide the rotational motion required to displace the fluid through the pump. The impeller contains a series of vanes or blades that help to increase the speed of the fluid. Like other wetted components of stainless-steel submersible pumps, the impeller is manufactured from stainless steel to minimize corrosion. Stainless steel submersible pump manufacturers classify impellers based on the position of vanes or blades, the direction of flow, and the suction type. In general, the pump impeller can be open, semi-open, or closed impeller. An open impeller is not covered on any side and is perfect for small and low-cost pumps. A semi-open impeller contains a backside shroud only and is suitable for liquid like stool, mud, junk, etc. A closed impeller has shrouds on the front and back sides, making it fit for pumping clean liquids only.

Figure: Closed and open impeller.

Shaft

The pump shaft is a rotary mechanical component, centrally located in the pump and riding on bearings. The pump shaft carries the impeller and connects the rotor assembly to the electric motor via coupling. During the pump operation, the pump shaft transfers the rotary motion from the motor to the impeller, which displaces the liquid through the pump. Stainless steel submersible pump manufacturers use stainless steel for pump shafts to overcome corrosion, heavy loads, and vibrations during the pump operation.

Bearings

The bearings carry the shaft and the impeller and ensure they align correctly with the fixed ends under the action of radial and axial forces. Bearings also serve to reduce the friction between the rotating shaft and the stator and contain the relative motion of the rotor assembly.

Intake section/ gas separator

The intake section also called the suction manifold supplies the pumping fluid to the impeller’s eye. Application with low bottom pressure may contain a significant amount of gases that can damage the pump. In such applications, the intake section is replaced with a gas separator which separates gas from the fluid when it enters the pump.

Electric cable

The electric cable delivers electric power to the stainless-steel submersible pump. The cable consists of a range of conductors that help to meet the motor requirement. Stainless steel submersible pump manufacturers also galvanized the electric cable to overcome extreme underwater conditions. Stainless steel pumps with single-phase motors have two cables while those with three-phase motors have three cables.

Valves

The stainless-steel submersible pump manufacturers also equip the unit with various kinds of valves to help with the pumping operation. The pump valves include the relief valves, drain valves, and ball valves. Respectively, these valves help to protect the pump from overpressure, drain the tank, and isolate the plumbing system from the pressure systems.

How does a stainless-steel submersible pump work?

A stainless-steel submersible pump is submerged and pushes water to the surface. It works by converting a motor’s mechanical energy output into kinetic energy of fluid and then pressure energy to push the pumped fluid to the desired location. When the pump starts, the pump rotor attached to it via coupling rotates at the same speed as the motor. As the rotor spins, a vacuum is created inside the pump casing due to the centrifugal effects of the impeller. The vacuum allows the pumped liquid to enter the pump casing through the pump inlet. When the pumped liquid strikes the impeller blades, the centrifugal force moves it radially and axially outwards until it enters the volute chamber at a very high velocity. In the volute chamber, the extreme velocity is converted into a high-pressure head, allowing the pumped liquid to discharge from the pump to the designated area through the delivery pipes.

Types of stainless-steel submersible pumps

Stainless steel manufacturers split the stainless-steel submersible pumps into different types depending on the specific applications of the pumps.

stainless-steel submersible sewage pump

The stainless-steel submersible sewage pump is used for handlings sewage, wastewater, or effluent. It features a fully 304 stainless-steel construction and a semi-open non-clogging type of impeller. It is suitable for hospitals, commercial buildings, municipal engineering, etc.

stainless-steel submersible pump for dirty water

This type of stainless-steel submersible pump is primarily used for pumping dirty water or water contaminated with aggressive chemicals because the pump material is highly corrosion-resistant. A submersible pump for dirty water can handle water containing suspended solids.

Stainless-steel submersible chemical pump

A chemical stainless-steel submersible pump is used in chemical industries to empty corrosive and abrasive liquids from tanks or sumps. Perfect for the pharmaceutical industry and general acid or corrosive water containing solid particles, etc.

Applications of stainless-steel submersible pumps

Stainless steel submersible pumps cater to a wide scope of applications in various industries, such as chemical, food processing, municipal works, wastewater treatments, petrochemical, etc. Some of the use of stainless-steel submersible pumps include the following:

- Stainless steel submersible pumps are used for cellar drainage.

- They are used in municipal works to dispose of wastewater, sewage, dirty water, and effluent.

- They are used for industrial water and well water lifting.

- Stainless steel submersible pumps are used for pumping groundwater.

- They are used for farmland drainage and irrigation.

- They are used for emptying mild chemicals from tanks or sumps.

- They are used to quickly and efficiently drain unwanted water bodies, e.g flood water.

- They are quiet because they operate below the surface of the pumped liquid.

Advantages of stainless-steel submersible pump

- Stainless steel submersible pumps do not require to be primed because they are submerged in the pumped liquid.

- They are suitable for handling corrosive and abrasive liquids.

- They are cavitation free in operation.

- They are highly versatile.

- They are highly energy efficient because it doesn’t spend energy sucking water into the pump.

- A stainless-steel submersible pump can efficiently resist the damaging effects of being submerged in any liquid medium because of the stainless-steel construction.

Disadvantages of a stainless-steel submersible pump

- Stainless steel submersible pumps can be prone to leaks and operation failures due to weary gaskets or corroded seals.

- It isn’t easy to carry out routine inspections and maintenance of a stainless-steel submersible pump because it is submerged in the pumped liquid.

- Stainless steel submersible pumps are more technical in design than the non-submersible pump; hence they are quite costly to acquire.

Troubleshooting a stainless-steel submersible pump

The motor doesn’t run

- The circuit breaker is tripped or the fuse is blown-out. Inspect the pump for a blown fuse and replace it. Reset the circuit breaker if necessary.

- The pump cables are broken. Inspect and change the cables if necessary.

- There is no power supply to the Control Panel. Ensure that the power cables are connected per the stainless-steel submersible pump manufacturer’s guide.

- Heavy sediments around the pump. Inspect the pump for build-up and clean it.

Zero pump discharge

- The pump is operating in reverse. Reverse the motor polarities. Check that the motor rotation direction follows the stainless-steel submersible pump manufacturer’s guide.

- The discharge pipe is blocked. Inspect and clean the discharge pipe.

- The impeller is clogged. Remove any blockage from the impeller.

The motor overheats

- The motor has failed. Inspect and replace the motor if it is necessary.

- There is a voltage spike due to a storm or lightning strike. Install the stainless-steel submersible pump with external surge protection.

- The pump is not fully submerged in operation. Check and fully submerge the pump if necessary.

Thermal trip

- The pump head is too low. Adjust the pump head or install a control valve to detect back pressure according to the set value.

- The stop level is too low. Verify the stop switch level from the stainless-steel submersible pump manufacturer’s manual and adjust accordingly.

- Driver overload. Ensure the pump is drawing the right amount of current.

Low pump flow rate

- The impeller is severely worn out. Inspect the impeller for wear and replace it if necessary.

- There is excessive clearance leading to fluid recirculation. Ensure that the impeller is of the correct size following the stainless-steel submersible pump manufacturer’s manual.

- The pump is reversed. Reverse pump polarities.

- The suction is clogged. Clear the suction from any debris.

- The discharge pipe is blocked. Inspect and clear any blockage from the discharge pipe.

Summary

A stainless-steel submersible pump is a pump featuring full stainless-steel construction, designed to operate below the surface of the pumped liquid. All the wetted components of stainless-steel submersible pumps are made from stainless steel. The pump motor is hermetically sealed and close-coupled to the pump body. The stainless-steel submersible pump manufacturers design the pumps primarily for handling clean, clouded, or slightly contaminated water. Due to the use of corrosion-resistant material and food-grade lubricant, stainless-steel submersible pumps are also suitable for food and mild chemical industries. Stainless steel manufacturers classify the stainless-steel submersible pumps into different pump types depending on the specific use of the pump, such as dirty water, sewage, or chemical pump. Stainless-steel submersible pumps are also available with single-phase and three-phase motors. They also can be with or without float switches for manual or automatic operation. Stainless steel submersible pumps offer many benefits, including cavitation-free operation, high energy efficiency, and the ability to self-prime and resist corrosion.