Vertical Split Case Pump

What is a vertical split case pump?

A vertical split case pump is a unique form of centrifugal pump featuring a vertically split casing with removable cover plates on the ends. The split casing design allows for easy disassembly of the rotor group without disturbing the pump alignment or the suction and discharge pipework, saving time during serving or maintenance of the pump’s internal components. The Vertical split case pump manufacturers mainly design the device for vertical installation to save on floor space. Vertical split case pumps are ideal for transporting raw, pure, or service water in the process industry, irrigation farmlands, water treatment plants, power stations, and the sugar industry. They provide excellent performance metrics with a maximum pressure head of up to 200 meters, a pump capacity of 5000 cubic meters per hour, and a maximum working temperature of 70 degrees Celsius. Vertical split case pumps are available in various configurations and construction materials, such as cast Iron, cast steel, ductile Iron, etc.

Figure: Vertical split case pump

Components of a vertical split case pump

Electric motor

The electric motor is the source of power for the pump. Generally, an electric motor has two main types: alternating current (AC) and direct current (DC) motors. The vertical split case pump mainly utilizes an alternating current engine, either a single-phase or a three-phase induction motor.

Casing

The vertical split pump has a vertically split with a double volute to help reduce radial bearing loads. The purpose of the pump casing is to house the rotor assembly (i.e., the shaft, impeller, shaft sleeves, and bearing housing) and carry the suction and discharge ports. In addition, the pump casing contains water pressure and prevents the liquid from leaking as it flows through the pump.

Figure: Vertically split pump casing.

Coupling

Vertical split case pump manufacturers fit a long coupling between the motor and the pump head. The coupling connects the motor’s driver shaft with the rotating pump shaft, ensuring the transfer of mechanical torque to the pump head with minimal losses. The long coupling design allows easy pump maintenance due to the quick access to the pump head without removing the motor. It also provides ample space between the pump and motor, which helps to protect the motor from fluid ingress in the case of seal failure.

Shaft

The shaft is a rotary mechanical component supported on bearings and usually coupled with the prime mover. Its primary purpose is to carry the impeller. Vertical split case pump manufacturers create the shaft from high-grade materials such as stainless steel and alloy steel to withstand corrosion and vibrations during pump operation.

Impeller

The impeller is the main rotary component in a vertical split case pump. It is created with a series of backward-curved vanes. It imparts kinetic energy and fluid pressure to water to flow through the pump and piping network. An impeller can be either open type impeller, which has no covers, or a closed-type impeller, which has shrouds on either side to strengthen the impeller. The vertical split case pump employs the closed-type impeller with either a single-suction or double-suction configurations

Figure: Pump impellers; a) single-suction design and b) double-suction design.

Bearings

The bearings support the pump shaft or the rotor assembly and align them correctly with the fixed ends under radial and axial forces. Further, the bearings also contain the rotor’s relative motion and minimize the friction between the rotating shaft and the stator.

How does a vertical split case pump work?

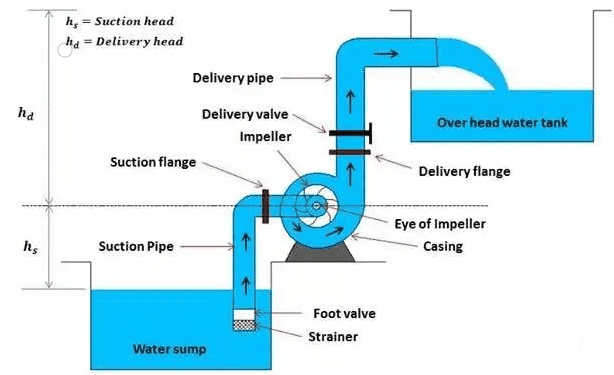

A vertical split case pump converts the mechanical energy of an impeller into the kinetic energy of water and then pressure energy to move it through the pumping systems. When the electric motor starts, the mechanical torque output is transferred to the impeller via the pump shaft and the coupling. As the impeller rotates, a void is created inside the pump, allowing the pumped fluid to flow into the pump casing and toward the impeller’s eye due to the external atmospheric pressure. As long as the impeller rotates, more liquid draws into the pump casing, and centrifugal force acting on the impeller blades causes the pumped liquid to move radially outwards, away from the impeller center of rotation, at high tangential velocity. The swirling flow at the exit of the impeller then enters into the diffuser, where the high flow velocity decreases due to the gradually enlarging flow path, leading to the conversion of kinetic energy into static pressure. Finally, the water discharges from the vertical split case pump at elevated pressure and flows to the desired location through the discharge port and delivery pipe connections.

Figure: Working of a vertical split case pump.

Types of vertical split case pumps

Single-suction vertical split case pump

A single-suction vertical split case pump consists of a single-suction impeller that draws water through a single inlet. Essentially, the whole volume of water flowing through the pump inlet enters the impeller blades only through one side. The centrifugal effect generates fluid pressure as the blades displace the liquid through the pump. It has a robust design and can cost half the price of a comparable double-suction pump.

Figure: Single-suction vertical split case pump.

Double suction vertical split case pump

A double-suction vertical split case pump features a double-suction impeller with two impeller eyes to admit water from both sides of the blades. The double-suction impeller splits the flow inside the pump, sending half of the flow through either eyes or inlets of the impeller. It has several benefits, such as lower axial thrust and excellent Net Positive Suction Head (NPSH). The doubles suction vertical split case pump can manage higher flow rates and has a longer service life rate than its single-suction counterpart.

Figure: Double-suction vertical split case pump

Applications of vertical split case pumps

The vertical split case pumps are extensively used to pump water in various applications, such as agriculture, mining, firefighting equipment, municipal wastewater plants, power stations, dewatering, marine, and cooling/heating conditioning. They are used to do the following:

- Vertical split case pumps are used to move water at high flow rates and low to medium pressure in residential and industrial water supply systems.

- They are used as booster pumps in booster stations.

- They are used to support fire protection equipment.

- They are also used in air conditioning systems to supply heating or cooling water.

- They are used to provide water to the sprinklers for irrigation and agricultural farmlands.

- They are used in construction applications to building supply water.

Advantages of a vertical split case pump

- A vertical split case pump is easy to maintain due to the long coupling between the electric motor and the pump head. The pump head can be accessed without removing the motor.

- They are highly reliable and energy efficient.

- They also save repair/servicing time. The split casing design allows for quick disassembly of the rotor assembly without interfering with the pump alignment.

- The split casing design also helps increase the suction performance and balance the hydraulic axial forces. The balanced axial thrust leads to increased bearing life.

- Vertical split case pumps occupy small floor space due to the vertical orientation.

- A vertical split case pump is more robust and fit for continuous use because the additional bearing assembly in the pump head relieves a significant level of strain from the motor during operation.

- Vertical split case pumps have independent motors and pump shafts, which means that only one will need to be replaced if damaged.

- Vertical split case pumps with double suction impellers can manage higher flow rates.

- They employ a long coupling, which provides adequate space between the motor and the pump head, preventing the pumped fluid from getting into the engine when mechanical seals fail.

Disadvantages of a vertical split case pump

- Vertical split case pumps cannot handle liquids with suspended solids and highly viscous fluids.

- Since they are vertical, the weight of the pump falls below the volute leading to stress concentration.

- Vertical split case pumps have a limited drive option because they can only be coupled to an electric motor.

- They require ample headroom for installations and maintenance.

Troubleshooting a vertical split case pump

The motor doesn’t run

- There is a tripped circuit breaker or a blown-out fuse. Inspect and reset the circuit breaker if necessary. Inspect the pump for a blown-out fuse and replace it.

- There is an open circuit in the thermal overload. Allow the vertical split case pump to cool, close any open circuit, and restart it.

- The motor is defective. Inspect and replace the motor if it is necessary.

- The motor is poorly installed. Ensure the pump is installed to the vertical split case pump manufacturers’ standards.

The pump’s discharge is low

- The impeller or check valve is clogged. Inspect and clear any blockage in the valve or impeller.

- The pump is operating in reverse. Ensure that the motor rotates in the direction indicated by the vertical split case pump manufacturer using the arrow on the pump casing. Be sure to reverse the motor polarities.

- The monomeric head is insufficient due to high friction losses that exceed the pump design. Increase the pump power. Ensure the pipes used in the piping network meet the diameter recommended by the vertical split case pump manufacturer.

- There is air in the pump or suction pipework. Be sure to fill the pump or piping network with water to drive out the air.

The pump’s driver is overloaded

- The Pump speed is too high. Ensure the pump operates within the speed range specified by the vertical split case pump manufacturer.

- Some pump parts are experiencing extreme mechanical friction. Inspect the pump assembly for any deflection or obstruction and correct it.

- Faulty pump motor. Inspect the engine for defects and repair or replace it if necessary.

The noise level is too high

- Some foreign materials are present in the vertical split case pump. Disassemble the pump and clean it.

- The impeller is damaged or worn out. Inspect and replace the impeller.

- Pump working in cavitation. Check that the suction line valves are fully open.

- The mounting plate and the foundation lack sufficient rigidity. Reinforce the foundation, and mount the vertical split case pump tightly.

- The pump is working outside the duty range. Ensure the correct duty range according to the vertical split case pump manufacturer’s guide.

The pump is experiencing excessive vibration

- The pump impeller is partially clogged. Inspect and clean the impeller.

- The pump shaft is oblique or unbalanced. Inspect the shaft, rebalance it as required, or replace it.

- Some pump components are loosely mounted in the pump body. Tighten any loose parts to the torque level recommended by the vertical split case pump manufacturer.

- Some of the vertical split case pump’s components are unbalanced. Inspect and rebalance the parts if necessary.

Summary

A vertical split case pump is a particular model of a centrifugal pump with a vertically split casing and either single suction or double suction impeller. The split casing design, together with a long coupling between the motor and pump head, allows for faster disassembly and servicing of the pump’s internal components. The vertical split case pump manufacturers usually design these units for vertical installation, which helps to save floor space significantly. Vertical split case pumps mainly suit the transportation of low-viscosity fluids, such as freshwater, seawater, and service water. They are evident in various residential, commercial, and industrial applications, such as irrigation farmlands, mining, firefighting equipment, municipal wastewater plants, and power stations. The benefits of vertical split case pumps include easy maintenance, space-saving design, and high efficiency and reliability. Since they have independent motor and pump shafts, only one shaft will need to be replaced if damaged. Vertical split case pumps are available in different designs and construction materials to meet various application demands.