High Chrome Slurry Pump

What is high chrome slurry pump?

This is a centrifugal pump made of chrome material and meant for transporting liquids and slurries. Slurries refer to solid and liquid mixtures, where the liquid serves as the mechanism of transport used to move the solids in a pump. The size of the slurries ranges from small (microns) in diameter to hundreds of millimeters in diameter. The size of the particle impacts the ability of the pump to transport the slurry in a pipeline. High chrome slurry pump manufacturers will help you to select the pump depending on the size and quality of the slurries to be transported. The use of chrome material in making this pump ensures high strength and ability to withstand corrosion due to corrosive liquids. The chrome material also ensures the pump is resistant to abrasive wear emanating from the slurries. This pump is operated by the use of an electric motor that provides mechanical energy to drive pump impellers. The pump is very versatile for use in applications such as mining, wastewater, paper and pulp, and chemical processing among others.

Figure: High chrome slurry pump

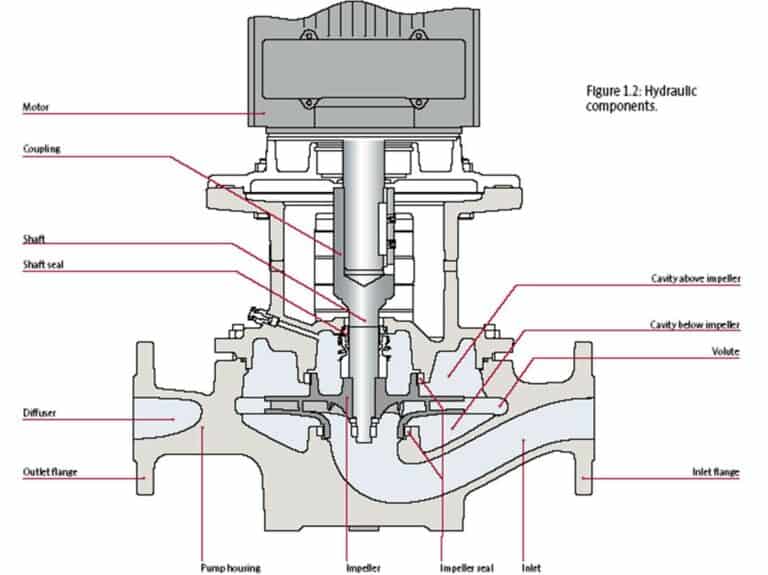

Components of a high chrome slurry pump

Motor

The motor is the source of power in the pump. It is connected to the electricity mains supply. It operates by converting electrical energy into mechanical energy. The mechanical energy avails itself through motor shaft rotation at high speed.

Pump shaft

This is a shaft in the pump which is connected to the motor shaft via a coupling to help transmit power to the pump. High chrome slurry pump manufacturers design this shaft as a solid shaft to ensure it has high strength enough to transmit the power needed to run the pump.

Impeller

This is a rotating component mounted on the pump shaft and rotates when the pump is turned on. The impeller rotation creates a vacuum in the pump which forces fluid to move from the storage into the pump. Also, this impeller is meant to impart kinetic energy into the fluid through its high-speed rotation.

Casing

The casing is an exterior part of the pump which contains the inlet and outlet ports. High chrome slurry pump manufacturers design the casing such that it helps to reduce the kinetic energy of the fluid from the impeller while it increases the pressure energy. The pressure energy is needed to move the fluid from the pump to the required destination. The casing also helps to seal off the fluid from the atmosphere to enhance pressure.

Suction line and valve

The suction pipe is used to connect the storage tank to the pump. It also comes with a suction valve which is used to open or close the fluid flow into the pump from the tank.

Discharge line and valve

The discharge pipe connects the pump to the pipe network. The discharge valve is used to regulate the amount of fluid that leaves the pump into the pipe network.

Mechanical seal

This component is used to seal off the fluid from leaking between the pump shaft and the casing while the shaft rotates.

Figure: Components of a high chrome slurry pump

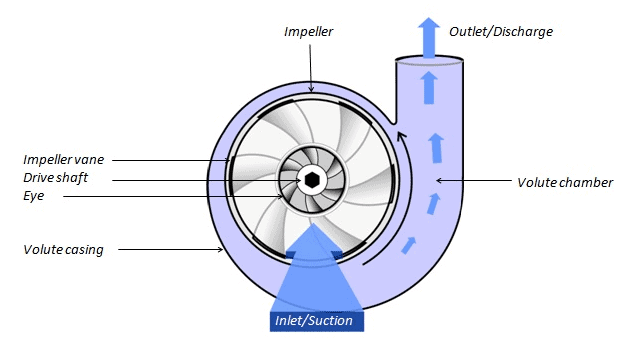

How does a high chrome slurry pump?

A high chrome slurry pump operates by using centrifugal force. To operate this pump, the motor converts electrical energy into mechanical energy using the motor shaft. This power from the motor is transmitted into the pump as speed and torque via the pump shaft. Due to the shaft rotation, the impeller mounted on the shaft starts rotating at the same high speed as the motor shaft.

This high-speed rotation creates a vacuum in the pump. A vacuum is a state in which the pressure in the pump is lower than the atmospheric pressure on the surface of the fluid being pumped. As such, the atmospheric pressure on the fluid forces it into the pump as a way of creating some pressure balance. Then fluid enters the pump into the impeller eye. The impeller imparts kinetic energy into the fluid as it spins at high speed. As such, the fluid’s kinetic energy increases and it proceeds into the casing. In the casing, the fluid velocity is reduced while the pressure energy is increased until the fluid enters the discharge pipe and into the pipeline.

Figure: Working of a high chrome slurry pump

Types of High chrome slurry pumps

Magnetic drive high chrome slurry pump

This is a pump that uses magnets to connect the motor shaft to the pump. This technology uses two magnets one on the outside and the other one on the inside of the pump. The outer magnet is connected to the motor shaft so that it rotates as the shaft spins. Due to the magnetic field pattern, the inner magnet rotates when the outer magnet rotates. Since this inner magnet is connected to the pump shaft, its rotation forces the impeller to rotate creating a vacuum in the pump and thus forcing fluid flow.

High chrome slurry pump manufacturers recommend this type of pump for use in applications that involve highly hazardous fluids such as corrosives and flammables whose leakage may lead to serious losses or legal action. This is because these pumps do not use mechanical seals to prevent fluid leakage between the shaft and the casing but they use magnetic technology. This technology is very reliable as it cannot cause any leakage common when mechanical seals wear out. However, this type of pump is more expensive compared to other pumps.

Self-priming high chrome slurry pump

This is a pump designed to prime itself every time it is started. When the pump is started, the impeller starts rotating, and thus it creates a vacuum on the impeller eye. As such, this vacuum draws air into the pump from the inlet end of the pump. At the same time, it produces a cylindrical liquid ring in the pump casing. This leads to the formation of a gas-tight seal which stops air from returning from the discharge end to the suction line. Bubbles of air that have been trapped in the pump are transported to the outlet port where the air is expelled and the liquid goes back to the pump reservoir in the pump through gravity. The liquid slowly rises the suction pipe as it is evacuated. The process keeps on until all the liquid replaces all the air in the pump and the suction line.

After all the air is removed, the pump starts the normal pumping process where liquid and contained slurries are discharged to the pipe network. High chrome slurry pump manufacturers design this pump to store some of the liquid once the pump turns off. This liquid is used to do the priming when the pump is started again.

Double suction high chrome slurry pump

This is a pump designed with two inlets. This pump has two impellers arranged back to back on the shaft. Such an arrangement is meant to balance axial thrust due to the high fluid flow. Such pumps are very reliable even when used for high fluid flow rates. This type of pump is used in applications where the flow rate will be too high for the inlet of a single impeller or when the inlet flow velocity of the first impeller needs to be reduced to prevent cavitation.

Submersible high chrome slurry pump

This is a high chrome slurry pump that operates while it is submerged in the liquid being pumped. This type of pump is mostly used in the transportation of sewage. This pump is designed with a cutting mechanism that helps to shred and cut large solids contained in the liquid into smaller pieces that constitute the slurry. However, there are other pumps designed without the shredding and cutting mechanisms and which are meant for use in applications where large solids cannot block the pump. High chrome slurry pump manufacturers design this pump with sensors that help the user to easily know when the pump has developed a problem or when the fluid in the pump is very low. This makes it easier as the operator will take action on the pump as soon as possible.

Applications of High chrome slurry pumps

- These pumps are used in chemical processing to transport chemicals and solids.

- They are used in the mining applications that involve the transportation of slurries and sludge.

- High chrome slurry pumps are used in municipal and private wastewater treatment and water supply.

- These pumps are used in steam power plants to supply water.

- They are used in crude oil transportation.

- High chrome slurry pumps are used to transfer paper and pulp products during manufacturing.

- They are used in oil sands and coal processing.

- They are used in sugar production.

Advantages of high chrome slurry pumps

- These pumps are resistant to corrosion and hence suitable for use in corrosive media.

- They are versatile as they can serve in various industrial applications.

- They are of various sizes to serve both small and large fluid flow rates.

- High chrome slurry pumps are of high strength and suitable to handle high pressure.

- They are resistant to abrasive wear.

- They are resistant to high levels of heat.

- They are of compact design.

- High chrome slurry pumps are easy to install and repair.

- It can be installed either vertically or horizontally.

- These pumps can handle low to highly viscous fluids like water and tar.

Disadvantages of high chrome slurry pumps

- These pumps are quite expensive relative to other centrifugal pumps.

- They are prone to shaft misalignment which can damage them.

- The use of this pump in handling hard slurries damages the impeller.

- Mechanical seals and rings wear which may cause fluid leakage.

Troubleshooting high chrome slurry pumps

No fluid flow after startup

- Too high suction lift. Reduce the suction lift by raising the suction tank or lowering the pump.

- Air in the suction line or pump. Fill the suction line and the pump with liquid.

- Motor rotation is reversed. Check the direction of shaft rotation is as indicated by an arrow in the pump casing.

- Incorrect motor speed. Check the motor frequency and supply voltage are as recommended by the high chrome slurry pump manufacturer.

- Clogged check valve, impeller, or strainer. Clean off blocking materials.

The pump does not produce any fluid flow

- Leakage through the suction line. Check the suction pipe for blockage and repair.

- Clogged impeller or check valve. Clean off blocking material.

- The suction valve closed. Open the suction valve.

- The discharge valve is closed. Open the discharge valve.

- The pump is not primed. Prime the pump as instructed by the high chrome slurry pump manufacturer.

Bearings overheating

- Coupling misalignment. Realign the pump and coupling accordingly.

- Too tight bearing covers. Loosen the cover.

- Insufficient lubricating oil. Lubricate the bearings as instructed by the high chrome slurry pump manufacturer.

Excess vibrations and noise

- Clogged impeller. Clean off blocking materials.

- Defective impeller. Replace the impeller.

- Coupling misalignment. Align the coupling and pump properly.

- Loose connecting bolts and nuts. Tighten the bolts and nuts.

- Lack of lubrication. Lubricate all moving parts according to the high chrome slurry pump manufacturer’s instructions.

Summary

A high chrome slurry pump is a pump made of high chrome material. This pump is used in applications that have liquid mixed with slurries. It operates by use of centrifugal force and it thus lies under centrifugal pumps. The operation of the pump is powered by an electric motor that runs impellers. The rotation of the impellers at high speed creates a vacuum in the pump that forces the liquid and slurries into the pump. High chrome slurry pump manufacturers produce various types of this pump which include magnetic drive pumps, self-priming pumps, submersible pumps, and double suction pumps among others. Applications of this pump include waste water, chemicals, mining, power plants, crude oil, and food industries, among others. The advantages of using this pump are high versatility, compact design, high strength, corrosion resistance, abrasive resistance, and ease of installation and repair.