Pump Manufacturer

NTGD Pump, Your Pump Manufacturer of Proven Quality & Trustworthy Service

Pump Manufacturer Based in China

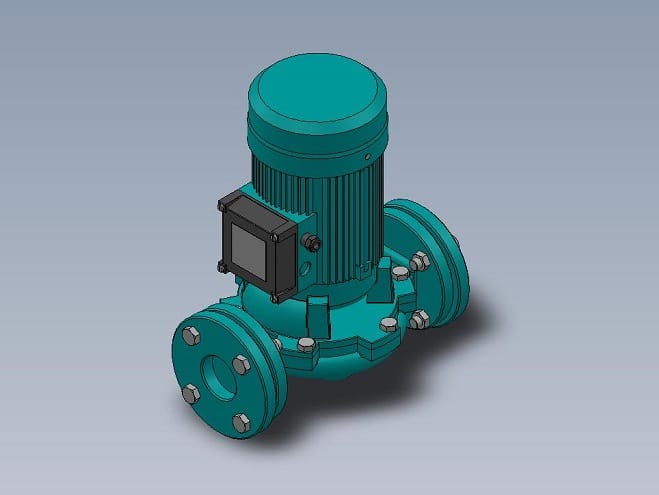

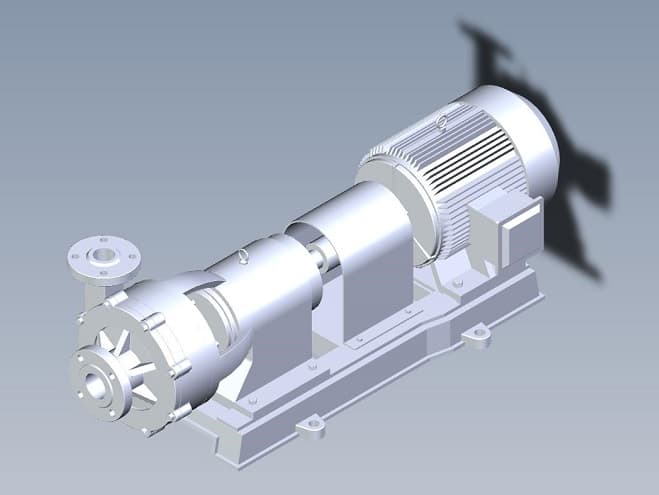

NTGD Pump Co., Ltd. Is ISO9001 certified comprehensive pump manufacturer integrating R & D, manufacturing, sales and service. We have advanced production technology, complete testing equipment, reliable quality and scientific management. At the same time, NTGD cooperates closely with many domestic scientific research institutes to make its products sell well all over the country and abroad.

Ask Us About Our Pump

At NTGD Pump, we manufacture variety of Pump. Request a free quote from us today!

Industries That We Serve

Pump manufacturers make pumps for use in different application such as:

- Transport water for domestic use.

- Transport sewage from homes to the sewage treatment plant.

- Transport chemicals in industrial areas.

- Transport water for irrigation in farmlands.

- Pump water for firefighting.

- Transport petroleum products that are corrosive and viscous.

- Transport fluid in the heating ventilation and a HVAC system.

- Dewatering of construction, mine, or pond site.

- Pumps are used to supply steam for power generation.

Never Compromised on Quality

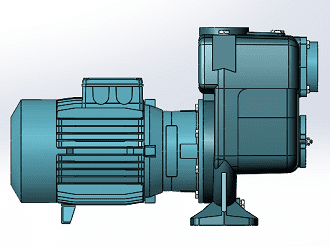

NTGD always adheres to the road of “quality for survival and quality for development”, and takes advanced design and manufacturing testing equipment as the means to make the whole process from design to manufacturing reach high standards and high reliability. All products adopt advanced design means such as CAD design software and CFD computational fluid dynamics software.

The products have gone through more than ten processes such as precision casting, hot forging, welding, heat treatment, finishing and assembly, and use advanced numerical control processing, plasma welding machine, full-automatic gas protection, semi-automatic vacuum fusion welding machine, overclocking vacuum heat treatment equipment, special processing machine All kinds of high-precision processing and testing equipment such as physical, chemical and flaw detection equipment fully realize the digital engineering of CAD / CAPP / CAM / CAE / PDM.

Our Mission

Relying on high-quality product quality and perfect service system, the products have been widely recognized by users. Customer satisfaction is our pursuit. NTGD pump industry is willing to work with colleagues to make progress and create a better tomorrow!

Certified

As long as we estblish NTGD pump, we applied for ISO 9001 certificate to establish our quality system. We have been certified for around 30 years.

These years NTGD pump get certified by ISO 45001 and ISO 14001. These management systems help us continuously improve quality.

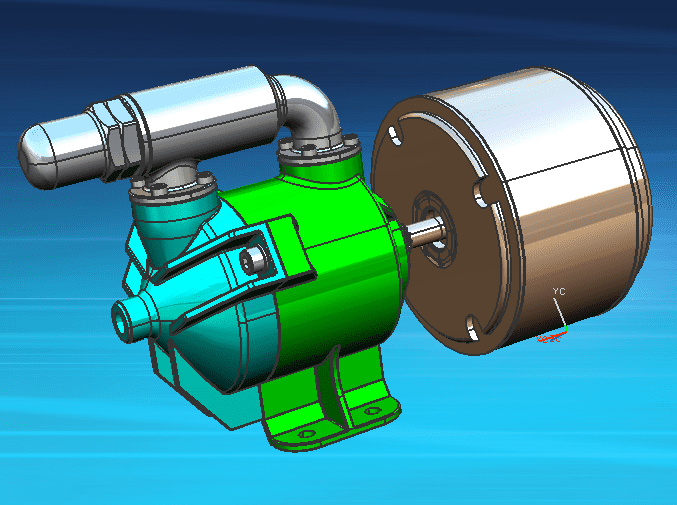

What is a Pump

A pump is a hydraulic machine used to convert mechanical energy into hydraulic energy. The hydraulic energy is usually in terms of pressure energy. Pump manufacturer makes the device to be able to move fluids that are either gas or liquid and at other times fluids with solid particles. A pump manufacturer makes pumps that are manual, electric-powered, wind-powered, or powered by a diesel engine.

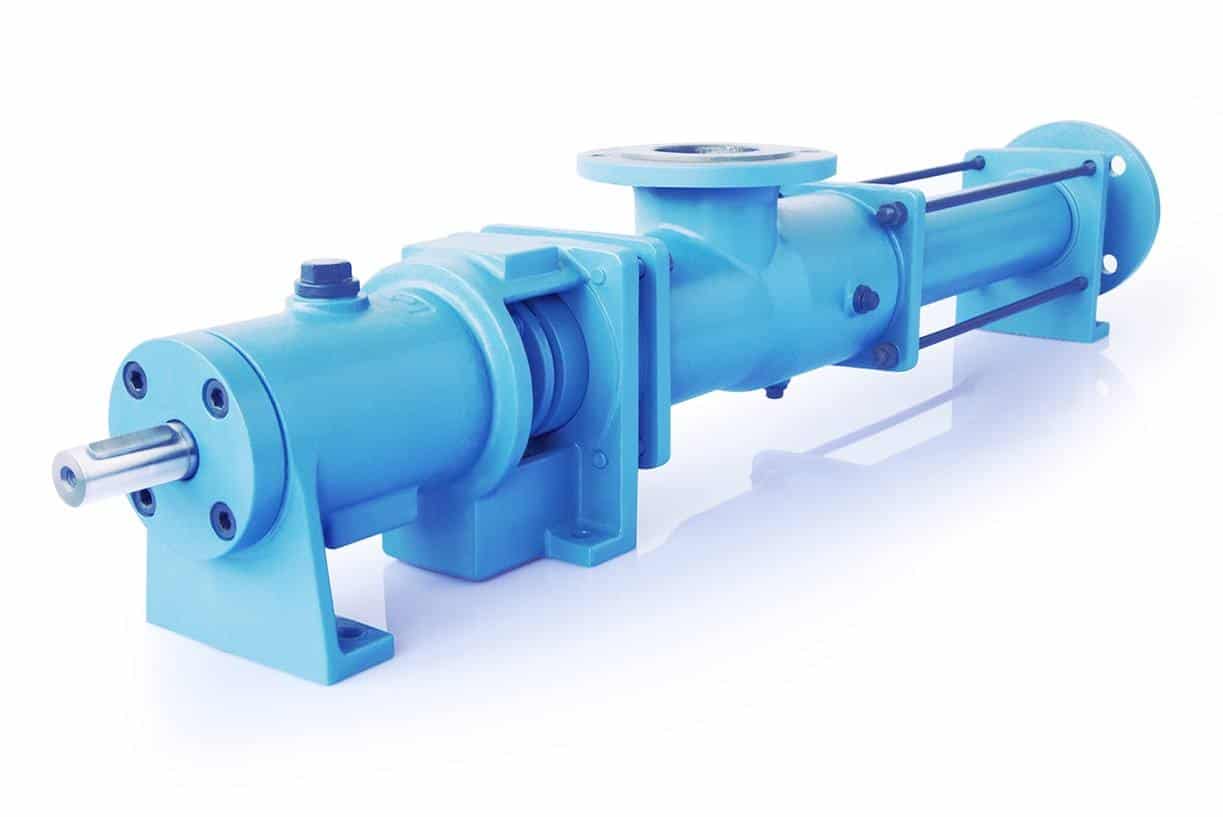

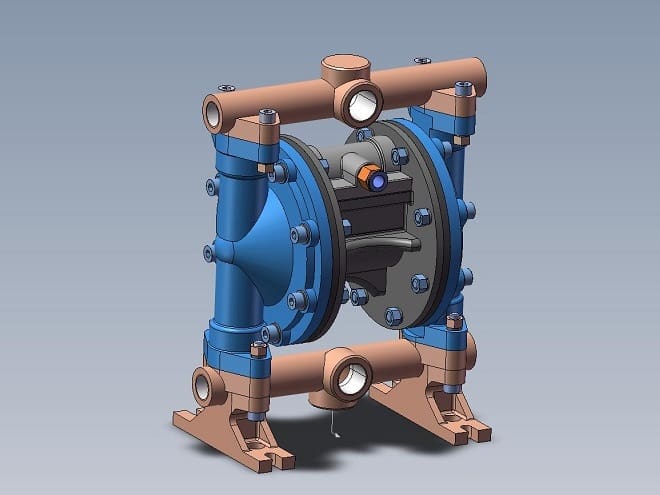

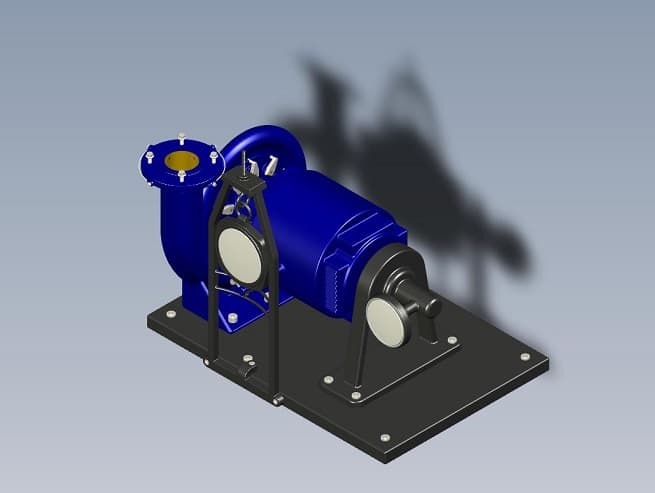

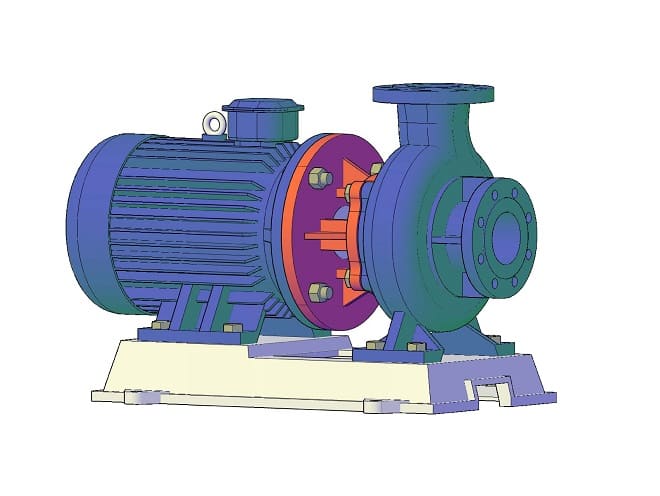

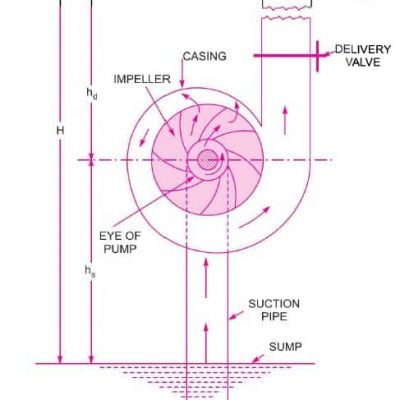

Pumps are of different sizes for use in different applications. There are two main types of pumps that is centrifugal pumps and positive displacement pumps. If the mechanical energy is transformed into pressure energy by the use of centrifugal force acting on the media being pumped, the pump is known as a centrifugal pump. When the mechanical energy is transformed into pressure energy by sucking the fluid into a pump cylinder by using a reciprocating piston to exert thrust onto the fluid and increase the pressure energy the pump is known as positive displacement or reciprocating pump. Between the two types of pumps, the most commonly used type of pump is the centrifugal pump. This is because the centrifugal pump manufacturers make them have simple designs that end up producing high efficiency and they are suitable for wider applications relative to positive displacement pumps.

How does the pump work?

A pump works by creating a vacuum that makes atmospheric pressure force fluid into the pump. The centrifugal pump manufacturer makes the pump to work by using centrifugal force to pump the fluid while a positive displacement pump manufacturer make the pump to work by pushing the fluid.

A centrifugal pump works by getting power from a prime mover which is either an electric motor or a diesel engine. The power from the prime mover is in terms of mechanical energy and kinetic energy (energy in motion). This mechanical energy is transmitted to the pump impeller from the motor or engine using a shaft. When the impeller gets this mechanical energy it starts rotating and as a result, it creates a vacuum pressure (pressure below atmospheric pressure) at the eye of the pump. Because of the vacuum, fluid starts entering the impeller eye in the axial direction. As the fluid enters the eye, it strikes the impeller blades. This makes the fluid rotate radially and axially outwards due to the centrifugal force of the rotating impeller. The impeller keeps rotating until the fluid goes past all the components. The blades on the impeller convert the mechanical energy of the fluid into speed and thus increase its flow speed. When the fluid passes the impeller, it enters into another part known as a diffuser which is mounted on the casing. The diffuser component is used to reduce the speed of the fluid and thus increase the fluid pressure. After fluid gets more pressure it discharges via the pump delivery pipe and flows to the required destination.

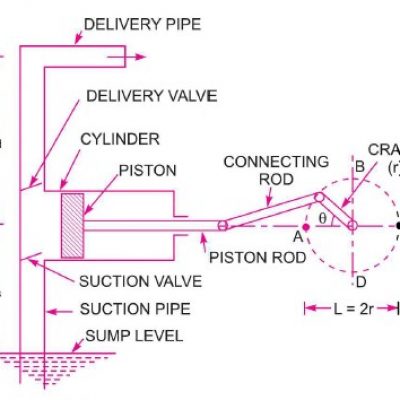

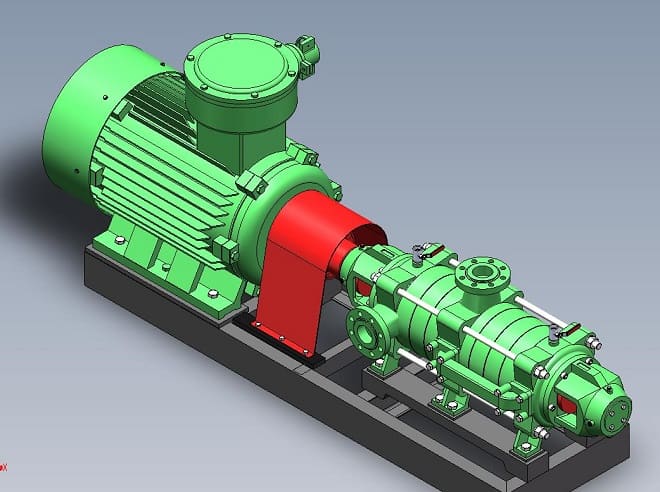

In a positive displacement pump, the piston reciprocates forward and backward in a cylinder. The piston moves by getting power from a prime mover which is either a motor or diesel engine. The prime mover transmits the power via a crankshaft and connection rod where the piston is connected. Delivery and suction pipes with delivery and suction valves are connected to the cylinder. The delivery and suction valves are non-return or one-way valves that allow fluid to flow in only one direction.

When the crank rotates, it makes the piston move forward and backward inside the cylinder. The piston movement to the right side creates a vacuum pressure in the cylinder. As such, the atmospheric pressure on the surface of the fluid becomes more than the pressure inside the cylinder. Consequently, the atmospheric pressure on the surface of the fluid forces the fluid into the suction pipe from the sump. The fluid then opens the suction valve to enter the cylinder. When the piston starts moving to the left side from the extreme right side, it increases the liquid pressure in the cylinder to be more than the atmospheric pressure. As such, the suction valve closes while the delivery valve opens. Then the fluid is forced to flow in the delivery valve to the required destination.