Submersible Pump

What is a submersible pump?

A submersible pump is a pump that is used to push fluid towards the surface rather than pull it. The submersible pump has an airtight sealed motor coupled to the body of the pump to help push fluid to the surface. This pump is under the category of centrifugal pump. Another name for a submersible pump is a well pump. A submersible pump is commonly used to pump water from a deep well. The submersible pump pushes fluid towards the surface by changing rotary speed into kinetic energy. It has diffuser blades that help to further convert the kinetic energy to pressure energy. Submersible pumps are beneficial in that they can prevent cavitation on the pump. As the name suggests, submersible pumps are entirely submerged in a fluid. As such, the primary purpose of submersible pumps is to pump fluids out of wells, tanks, or other vessels.

How does a submersible pump work?

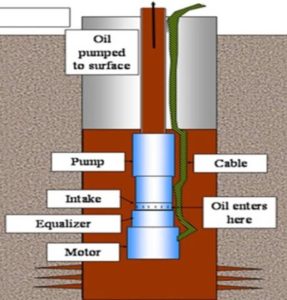

A submersible pump is an airtight electro-mechanical device sealed with an electric motor. The primary working principle of a submersible pump is similar to that of other centrifugal pumps as it falls under the centrifugal pump categories. A submersible pump works by pushing the fluid towards the surface. It works while it is completely submerged in the fluid being pumped. The fluid gets into the pump through the foot valve striking the impeller. The impeller is a rotating part with several blades. The impeller is connected to an electric motor using a shaft. The impeller rotates at the same speed as the shaft. As the fluid being pumped strikes the impeller blades, the blades convert fluid’s kinetic energy to speed and further increasing the fluid’s speed. The fluid then moves to the diffuser. The diffuser helps to convert the speed of the fluid into pressure energy. As such, the diffuser increases the fluid’s pressure. Finally, the pressurized fluid exits through the outlet valve.

Figure 1: Working principle of a submersible pump.

Submersible pump Types

There are several types of submersible pumps. The most common types of submersible pumps are:

- Stainless steel submersible pump.

- Deep well submersible pump

- Oil-filled submersible pump

- Bottom suction submersible pump

- Water cooler submersible pump

- Crompton submersible pump

- Mixed and axial flow pump

- Submersible utility pump

Stainless steel submersible pump

This type of submersible pump is known to perform better relative to cast iron pumps. As the name suggests, this pump is usually covered completely with stainless steel thus the name stainless steel submersible pump. It works while it is completely submerged in the fluid being pumped. Stainless steel submersible pump manufacturers make the pumps in a way that makes them resistant to acidic corrosion. It is used to transport weakly acidic or hot water.

Figure 2: Stainless steel submersible pump.

Deep well submersible pump

The deep well submersible pump is a common type of submersible pump. This type of submersible pump is used to pump water in deep wells to the desired area or home. It works while it is immersed fully in the water. It has an electric motor connected to the pump body. This pump can be used to transport water or weak acidic fluid.

Figure 3: Deep well submersible pump.

Oil-filled submersible pumps

Oil-filled submersible pump employs electric motor submerged in oil. This type of submersible pump is used to pump water to drainage systems, mountain areas, irrigation for farming, service water, lifting water in wells, and water supply in houses, hills among others. This type of pump has oil injection used for cooling motor. The oil in this pump does not freeze and thus this pump can be used in cold climatic regions. This type of submersible pump is designed in a way that makes it easy to restore and install.

Figure 4: Oiled filled submersible pump.

Bottom suction submersible pumps

Bottom suction submersible pumps are used often in mining, rivers, swimming pools, dewatering, and lakes. This type of submersible pump is designed with a guide sleeve. This pump sucks water from a well while ensuring effective cooling of the motor. These pumps are easier to install relative to other pumps. This pump is also known for its high head.

Figure 5: Bottom suction submersible pump.

Water cooler submersible pump

Water cooler submersible pumps are mostly used in industrial areas, agricultural irrigation, providing residential water, among other applications. The motor on this submersible pump can be set while underwater for its operation. The motor can be cooled by injecting freshwater. This pump is best suitable for pumping high-quality water.

Figure 6: Water cooler submersible pump.

Crompton submersible pump

This pump is made using cast iron material and it works on a single impeller. It can work on fluid with solids as large as 30 mm. It has a cable hood made of stainless steel. This type of submersible pump is commonly used in sugar industries, paper mills, sewage treatment plants, swimming pools, under-construction buildings, restaurants, and hotels.

Figure 7: Crompton submersible pump.

Mixed and axial flow submersible pumps

This is the submersible flow that is mostly used in sewage drainage, sewage treatment, drainage, river drainage, overflow control, and pumping stations for water solidification. It is made to have massive flow and non-clog properties that enhance its working conditions. Also, this pump has a triple seal system which helps to enhance pipeline life by preventing it from leaking.

Figure 8: Mixed and axial flow submersible pumps

Submersible utility pump

This is a submersible pump that is multi-purpose and multi-functional. It is used to remove stagnant water from outdoor and residential areas as well as remove aquarium drainage. They are very famous because they have superb features. A submersible utility pump can submerge fully in water for a long duration of time for use in large applications. It has both manual and automatic settings. It is made of cast aluminum making it light in weight weighing around 9 pounds. Submersible utility pump manufacturers make this pump free from corrosion and with a pumping capacity of 27 gallons per minute pumping capacity. This pump is also portable.

Figure 9: Submersible utility pump.

Components of submersible pump

The components of the submersible pump are:

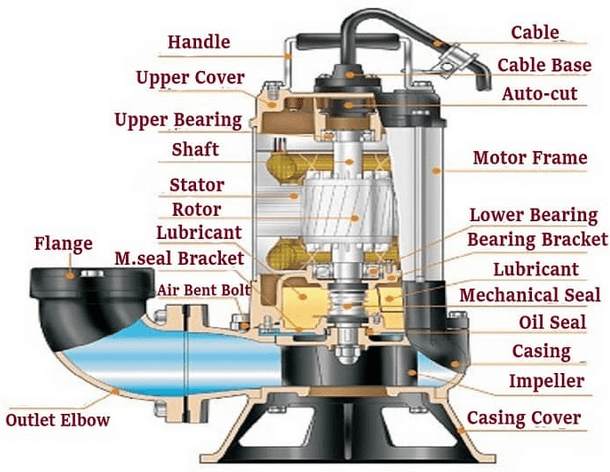

Clamps, Safety rope, Pump cable, Check valve, pressure switch, Pressure gauges, Flow control valves, Torque arrestor, Tank tees, Inlet and outlet valve, Relief valve, Impeller, Ball valves, Sediment filter, casing.

Figure 10: Components of submersible pump.

Check valve

The check valve is used to stop fluid from flowing backward inside the pump. This valve is also known as a non-return valve. The number and location of check valves required for a pump depends on the working depth. Factors considered when installing check valves are:

Fluid volume, hose, fluid flow velocity, pressure drops on the valve, weight of the pump, and hose friction loss.

Safety rope

The safety rope on a submersible pump is used to connect the pump. The main use of the safety rope is to prevent the separation of the pipe which can result to pump loss in the base of the tank or well. In case of a failure of the riser pipe, the safety rope will offer backup helping the installer to pull the pump from the well. Before the pump is hung in the borehole or well, it should be already secured with this rope.

Clamps

Pipe clamp helps in sealing pipe against insert fitting making a secure watertight seal and pull-off connection.

Pump cable

This part of the submersible pump is used to transfer electric power to the pump. The submersible pump cable uses 2 or 3 wires.

Pressure switch

The pressure switch is used to regulate the submersible pump operation. It is made with a built-in membrane moving forward and backward exchanging the fluid pressure. The pressure switch is made in standard, medium, and heavy-duty models to control various electrical and pressure ratings.

Pressure gauge

Pressure gauges in submersible pumps are used to monitor pump operational status.

Impeller

The impeller is the rotating part of a submersible pump. It has multiple blades fixed on it. It is used to convert the kinetic energy of the fluid into speed.

Inlet and outlet valves

The inlet valve is used to suck fluid into the pump. The outlet valve is used to discharge the fluid from the pump.

Priming of submersible well pump

A submersible well pump is a pump used to pump water in well or boreholes. This type of pump works by combining the working principle of centrifugal and injector pumps to transport fluid. One of the main factors for submersible well pump to work well is its priming. The procedures for priming a submersible well pump is:

- The pump is turned off and detached from electrical switches.

- Inspection of the pump for damage or cracking is done.

- The rubber or plastic prime plug on the top of the pump is eliminated. Then water pipe is inserted into the hole at the top of the pump.

- Water is transferred into the pump housing via a water tube or pipe. The tube or pipe is allowed to move in the pump housing until fluid starts moving out when the housing is full.

- The water pipe is removed and prime plug is partly inserted in the hole at the top of the pump. The pump system is turned off until no air bubble are coming from the plug base.

- If air bubbles are still coming from the pump, remove the prime plug and fill the pump housing. The above procedures are repeated and prime plug in inserted again partially into the hole. The pump is turned on until air bubbles are not coming out.

- The whole process is repeated until the liquid starts flowing out of the pump rather than air. Next, the prime plug is inserted full into the pump hole.

Advantages of submersible pumps

- Submersible pumps are free from cavitation.

- Submersible pumps have high efficiency relative to other pump types.

- Submersible pump cable can be used in either saltwater or freshwater.

- Submersible pumps do not need manual pumping because they are usually submerged in the fluid to be pumped and they get primed while in the fluid.

- Submersible pumps work quietly.

- Submersible pumps are manufactured in a way that makes them control both solids and liquids.

- Submersible pumps are energy saving as they suck water into themselves by use of fluid pressure.

- Submersible pumps are manufactured to work comfortably while submerged in fluid, unlike other pumps.

Disadvantages of submersible pumps

- When submersible pumps lack water the motor can overheat.

- If submersible pumps seal is damaged, it can cause leakages and thus damage internal parts of the pump.

- When the submersible pump is not submerged completely, it can be significantly damaged.

- Submersible pump is always submerged deep underground making it hard to diagnose its technical problem.

- Submersible pumps have a high cost compared to non-submersible pumps.

- Different applications need different types of submersible pumps.

- Submersible pump motor if not properly taken care of it can overheat.

- Submersible pumps are expensive because of their mechanical properties.

- Because submersible pumps are ever submerged in the fluid it makes it hard to make their repairs.

- Maintenance of submersible pumps is complicated.

Applications of submersible pumps

- Submersible pumps are used to pump fluids in wet wells, drains, and wells.

- Submersible pumps are used in oil production, dewatering, supply of drinking water, and irrigation of farmland.

- Submersible pumps are used in pools and plants to pump sewage that gets in buildings, sewers, and building lots.

Submersible pump troubleshooting

- The pump is not running. This could be due to a blown fuse, motor starter overload has tripped. When this happens the blown fuse needs to be replaced. However, when the fuse flows again, the drop cable and electrical installation need to be checked. For the starter motor overload tripping, then the motor starter overload needs to be reset.

- The pump is running but no fluid is coming out. This could be due to a closed discharge valve. When this happens, the discharge valve needs to be open. Again, this problem could be due to the non-return valve being stuck in the shut position. In this case, the pump needs to be pulled out and cleaned or the non-return valve is replaced.

- The pump is running at low capacity. This could be due to a choked discharge pipe. In this case, the discharge pipe needs to be replaced or cleaned. Also, this could be due to the non-return valve being blocked. In this case, the pump needs to be pulled out and the return valve replaced. Another reason could be due to the riser pipe and pump being partly having some impurities. In this case, the pump is pulled out and cleaned or replaced accordingly, and then clean the pipes.

- The pressure switch is defective. This can be solved by replacing the pressure switch or reducing the pressure setting.

Summary

This article has discussed details about submersible pumps. Submersible pumps are pumps used to pump fluid by pushing it towards the surface rather than pulling it. A submersible pump works while submerged in the fluid being pumped. This pump has an air-tight sealed motor coupled to the pump. Submersible pumps are under types of pumps known as centrifugal pumps. There are around 8 types of submersible pumps each of which is used to push a certain type of fluid towards the surface. This makes this type of pump to have several applications such as use in pumping safe drinking water from boreholes, pumping sewage, pumping irrigation water, drainage, and oil production among others. This pump has many advantages as well as disadvantages. However, manufacturers and customers have found that the advantages outweigh the disadvantages by a great margin.