Self-priming Sewage Pump

What is a self-priming sewage pump?

A self-priming sewage pump is a special type of centrifugal pump that can hold the necessary amount of pumped liquid inside the pump body for initiating the pumping process. Simply put, the self-priming sewage pump always contains the requisite start-up liquid inside the pump’s chamber or body. self-priming sewage pump manufacturers design the parts with designed with close tolerances to help trap liquid within the pump’s body, preventing it from returning from the discharge side to the suction side when the pump stops. The continuous availability of the pumped liquid within a self-priming sewage pump helps to better deal with “air pockets”. Air pockets refer to the accumulation of air bubbles within the pump’s working mechanism, which may interfere with the pump’s operation. Self-priming sewage pumps overcome air binding by initially mixing any residual air in the pump’s working mechanism with fluid during the priming process. The self-priming sewage pump offers the potential for increased operating efficiencies in a variety of repeated yet intermittent operations.

Figure: Showing a self-priming sewage pump

Unlike the standard centrifugal pump, the self-priming sewage pump doesn’t require the user to fill up the pump’s chamber with the pumped liquid to drive out the air before starting operation. The presence of air in the standard centrifugal pump may cause various challenges, such as overheating and pump failure. Therefore, a self-priming sewage pump overcomes such challenges by automatically evacuating air from the pump system at the start-up before pumping the fluid. The self-priming sewage pump is mainly used in sewage handling, industrial wastewater, and sewage sludge applications. However, it is also perfect for construction, dewatering, and flood control. Because the pump is self-priming, it can be mounted high and dry at floor level with only the suction line in the liquid. Self-priming sewage pump manufacturers design the pump so that when the pump has run once it will automatically contain sufficient liquid to self-prime in the next operation cycles. Nevertheless, when starting an empty self-priming sewage pump, the pump must be primed manually. Failure to which would lead to damage to mechanical seals and other pump’s internal components.

Components of a self-priming sewage pump

Electric motor

The function of the motor is to provide the mechanical power to run the pump. It works by converting electrical energy into mechanical energy. It consists of a stator, armature or rotor, and commutator. An electric motor can be either an AC motor or a DC motor. Ac motors work with alternating current, while Dc motors operate with direct current.

Volute (Casing)

The casing is a narrow air- passage surrounding the impeller. The casing acts as a pressure containment vessel and has suction and discharge ports. It contains the liquid and directs the flow into the pump through the suction pipe and out of the pump through the delivery pipe. The self-priming sewage pump’s volute is usually made of cast iron or cast steel to prevent corrosion in the extreme sewage environment. Self-priming sewage manufacturers also prefer such materials because they have a good casting performance, wear resistance, and high portability.

Impeller

The impeller is a rotor that serves the role of increasing the kinetic energy and pressure of the fluid. It is fitted with a series of backward-curved vanes. It is usually mounted on the pump shaft and housed in a watertight casing.

Suction pipe

The suction pipe consists of two ends where one end connects to the pump inlet while the other dips into the pumped fluid’s container. The lower end of the suction pipe is fitted with a foot valve to prevent the backward flow of water and a strainer to prevent the entry of foreign bodies into the pump

Delivery Pipe

The main purpose of the suction pipe is to lift fluid to the required area. The suction pipe contains two ends with one end connected to the outlet of the pump while the other end delivers the pumped fluid at the desired height.

Bearings

The bearings primarily support the shaft or the rotor and align them correctly with the fixed ends under the action of radial and axial forces. It also helps to contain the relative motion of the rotor and to minimize the friction between the rotating shaft and the stator.

Shaft

The shaft is a rotary mechanical component supported on bearings. Its main functions are to carry the impeller. It is usually coupled with the prime mover. Self-priming sewage pump manufacturers usually consider stainless steel and carbon steel materials for the pump shaft because they are strong and can resist vibration

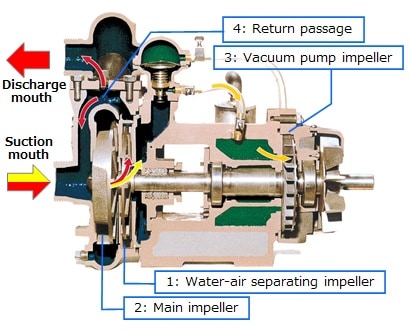

Figure: Components of a self-priming sewage pump.

How does a self-priming sewage pump work?

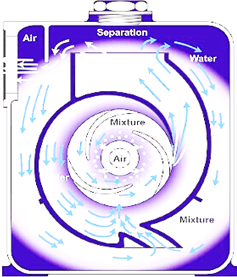

The self-priming sewage pump first evacuates air from the suction line and pump system during the priming cycle. In the priming cycle, the pump recirculates the liquid in the pressure head, creating a partial vacuum to discharge liquid and drive out any air. In the process, air and water in the pump casing mix and the resulting mixture moves radially through the pump’s body. The air naturally tends to rise while the air-free water flows back down by gravity into the pump casing where it mixes with the air coming from the suction line. And the process repeats until all air is removed from the pump system.

Figure: Self-priming sewage pump working process

When all the air has been evacuated, a partial vacuum is created in the suction line, and the atmospheric pressure outside forces the pumped liquid to flow into the pump casing via the suction inlet. The rotation of the impeller admits the liquid into the eye of the impeller. The centrifugal force acting on the blades displaces the liquid radially and axially outwards while increasing its kinetic energy until it passes through all the components of the impeller and enters the volute chamber. In the volute chamber, the speed of the fluid slowly decreases due to the gradually expanding flow path, and the high kinetic energy of the fluid converts into static pressure energy. The fluid then enters the discharge pipe at a very high pressure which allows it to move to the required location.

Types of self-priming sewage pumps

Horizontal self-priming sewage pump

This type consists of a horizontally oriented shaft with a long coupling between the driver and the pump head. It is suitable for use where there is limited vertical space.

Figure: Horizontal self-priming sewage pump.

Vertical inline self-priming sewage pump

The vertical inline self-priming sewage pump comprises a vertically oriented shaft with a close coupling between the driver and the impeller. Additionally, the inlet and outlet port orients straight in the piping system, or their centerline is on the same level.

Figure: vertical inline self-priming sewage pump.

Applications of self-priming sewage pumps

Self-priming sewage pump perfectly caters to sewage handling, industrial wastewater, municipal waste handling, and sewage sludge applications. Common uses of the self-priming sewage pump include the following:

- Self-priming sewage pumps are used in municipal work and pumping stations to discharge sewage

- Self-priming sewage pumps are also used for sewage transfer in treatment plants

- They are used also used for pumping industrial wastewater

- Self-priming sewage pumps are also used for moving sewage from septic tanks in private homes and commercial buildings.

- They are used in chemical industries to transport slurries, corrosive liquids, and liquid with suspended solids

- Self-priming sewage pumps also apply in construction, dewatering, and flood control.

- They are also used for greywater or effluents in various manufacturing industries

Advantages of a self-priming sewage pump

- A self-priming sewage pump is mounted above the liquid source; hence less infrastructure is required to set them up.

- A self-priming sewage pump is easy to maintain. When service or maintenance is required, it can be completed easily with common hand tools. There are no long drive shafts to install and align, and no hoists or cranes are required.

- A self-priming sewage pump is safer for the operators because it doesn’t have mechanical equipment in the well and also doesn’t require hoists or cranes.

- Self-priming sewage pumps are easier to access because they are installed at the ground level

- In comparison to the submersible counterparts, self-priming sewage pumps will continue to pump liquids even after the pump is no longer submerged in a liquid tank or vessel.

- A self-priming sewage pump is perfect for intermittent sewage handling applications because it eliminates pump priming stages on start-up.

Disadvantages of a self-priming sewage pump

- A self-priming sewage pump is often overlooked because it isn’t as commonly used as either standard centrifugal pumps or submersible pumps.

- Self-priming sewage pumps have a limited suction lift (up to a maximum of 7.6 m)

- Self-priming sewage pumps have a limited net pressure suction head (NPSH).

- These pumps are mostly larger than other centrifugal sewage pumps to ensure enough volume for priming.

Troubleshooting a self-priming sewage pump

Pump slow to prime or not priming

- The suction line could be leaking. Check for leakage by wrapping cling wrap around each joint; repair the leakage.

- The pump speed is low. Adjust the pump speed to the level recommended by the self-priming sewage pump manufacturer.

- The suction line is too long or the diameter too large. Ensure the pipe diameter meets the self-priming pump sewage manufacturers’ specifications.

The pump fails to start

- The fuse is blown or the circuit breaker is open. Replace the fuse, and reset the circuit breaker.

- Shortcomings in pump wiring. Inspect the pump for loose connections or broken wires and fix them. Check that pump’s wiring is correct according to the sewage pump manufacturer’s wiring diagram.

- An open circuit in the thermal overload. Allow the pump to cool down and restart the pump.

The Pump is clogging frequently

- The pump is operating too far left on the self-priming pump manufacturer’s curve. Speed up the pump.

- The impeller is unsuitable for the application. Replace the impeller with a solid handling impeller.

- Fit a strainer to the suction line

The pump doesn’t provide the rated flow rate.

- The suction line is partially blocked. Inspect and clean the suction line.

- mismatch of the motor voltage and the line supply voltage. Ensure that the motor supply voltage meets the self-priming pump manufacturer’s specification on the nameplate.

Noisy operation

- Either the bearings or impeller is damaged or worn out. Inspect and replace the impeller or bearings necessary

- There could be foreign material in the pump. Disassemble the pump and clean it.

- The pump is vertexing. Vertexing is the pulling of air from the surface of the liquid. sometimes this manifest in the form of a whirlpool on the surface of the liquid. Lower the suction line, and increase the diameter of the suction line.

- The mounting plate and foundation lack sufficient rigidity. Fasten the mounting plate tightly and the torque level specified by the self-priming pump manufacturer.

Summary

A self-priming sewage pump is a type of pump designed to always hold the necessary amount of pumped liquid inside the pump’s body for initiating the pumping process. A self-priming sewage pump’s working parts are fitted with close tolerances to trap liquid within the pump’s body. This also helps to prevent the pumped fluid from returning from the discharge side to the suction side when the pump is not operating. The self-priming sewage pump effectively deals with the air binding challenge by initially mixing any residual air within the pump’s working mechanism with fluid during priming. Self-priming sewage pumps provide high operating efficiencies because they eliminate manual priming cycles before pump operation. Self-priming sewage pump manufacturers design them to excellently cater to sewage handling, industrial wastewater, and sewage sludge applications. Self-priming sewage pumps can provide the safest and most cost-effective pump solutions if used within their hydraulic limits. They are also easy to install and maintain as they do not need service personnel to enter the sump.