Teflon Lined Magnetic Drive Pump

What is a teflon lined magnetic drive pump?

This is a magnetic drive pump whose interior is covered with Teflon material. Teflon is very good at resisting corrosion and thus such pumps are recommended for use in applications that involve corrosive products such as alkalis and acids. Teflon lined magnetic drive pump manufacturers design the pump to operate using magnetic technology. The pump uses two magnets arranged with opposite poles to create a magnetic field. The magnets help the pump impellers to rotate when the motor is started. This technology is very good because it helps to prevent fluid leakage which is very necessary when the pump has to transport hazardous and corrosive fluids like acids. Leakage of such fluids can cause environmental damage or cause legal action against the user. These pumps are also recommended for use in transporting other non-corrosive and non-hazardous products such as fresh water to help prevent losses through leakage.

Figure: Teflon lined magnetic drive pump

Components of a Teflon lined magnetic drive pump

Electric motor

The motor is the component that powers the pump. It is connected to the electricity mains supply and it converts the electricity into mechanical energy. The mechanical energy is in terms of kinetic energy when the motor shaft rotates.

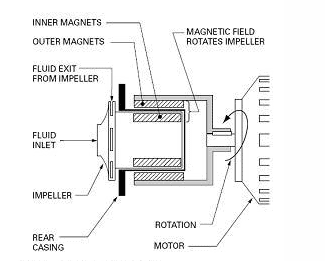

Magnets

Two magnets are the drive magnet and the driven magnet. The drive magnet is also known as the outer magnet and it is attached to the motor side. The driven magnet is also known as the inner magnet as it is mounted inside the pump. When the drive magnets rotate due to motor rotation the inner magnets rotate at the same speed forcing the impeller to rotate.

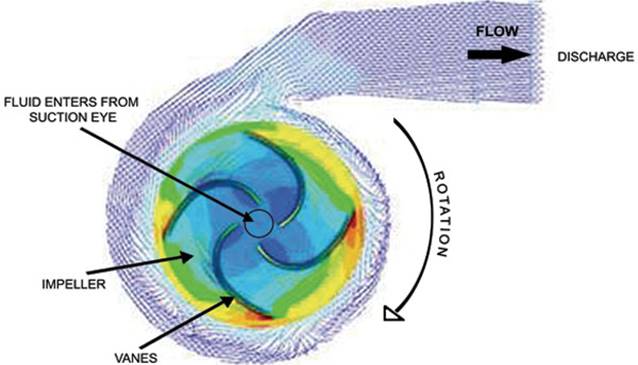

Impeller

The impeller is a component that has curved vanes. The impeller is mounted on a shaft that is supported by bearings. The impeller is forced to rotate by rotation of the inner magnet. The work of the impeller is to create a vacuum in the pump to force fluid into the pump and also to impart kinetic energy onto the same fluid so that it can flow to the required destination.

Impeller shaft

The impeller shaft is the shaft on which the impeller is mounted. The work of this shaft is to rotate the impeller due to the magnetic force created by the outer and inner magnets. Teflon lined magnetic drive pump manufacturers make the shaft using strong metallic materials like stainless steel and carbon steel to ensure it can afford to transmit the torque needed to turn the impeller and thus create the pump power needed.

Casing

This is the part of a Teflon lined magnetic drive pump that houses the internal parts of the pump. It also serves to convert the fluid’s kinetic energy imparted by the impeller into pressure energy needed to transport the fluid to the required location. This energy transformation enhances stable fluid flow. Teflon lined magnetic drive pump manufacturers design the pump to use one of three casings which are a casing with guide blades, a vortex casing, and a volute casing.

Suction pipe

This is a pipe with two ends where one end is connected to the pump and the other end is submerged into the liquid source or sump. The work of the suction pipe is to convey liquid from the source/sump into the pump.

Figure: Components of a Teflon lined magnetic drive pump

How does a Teflon lined magnetic drive pump work?

The pump employs magnetic technology to operate. This technology involves using two magnets the drive and the driven magnets. The drive magnet (outer magnet) is connected to the motor side while the driven magnet is connected inside the pump. To start the Teflon lined magnetic drive pump, the motor is turned on. As such, the motor starts rotating through its shaft. This motor shaft rotation forces the outer magnet to start rotating. With the outer magnet rotating, the inner magnet also starts rotating instantly due to the effect of the magnetic field. The rotation of the inner magnet forces the impeller to start rotating through the impeller shaft.

Due to the impeller rotation, a vacuum is created inside the pump. It is through this vacuum that fluid in the sump is sucked into the pump by atmospheric pressure. When the fluid enters the pump, it gets more kinetic energy from the impellers which increase its velocity. The fluid then proceeds to the casing where its velocity is reduced while its pressure energy is increased. The fluid then gets enough pressure energy and it exits the pump through the discharge port as it moves to the required destination through pipes.

Figure: Working of a Teflon lined magnetic drive pump

Types of Teflon lined magnetic drive pumps

Vertical Teflon lined magnetic drive pump

This is a pump that is installed in a vertical orientation. This pump is recommended for use in applications that have small floor space for installation. Teflon lined magnetic drive pump manufacturers produce varieties of this pump with long shafts. These shafts help the pump to be installed even in deep wells and pits. This pump is among mixed flow and axis flow pumps. The pump can have one impeller or several impellers. The pressure head for this pump depends on impeller length and rotation speed. The more the impellers the more pressure energy the pump will produce. However, this pump has the challenge of vibration and noise due to the long shaft. It also has the challenges of repair due to its location.

Figure: Vertical Teflon lined magnetic drive pump.

Horizontal Teflon lined magnetic drive pump

This is the pump designed such that the location of the head is adjacent to the motor. The motor and the pump are installed in a horizontal plane. This is the most commonly used type of Teflon lined magnetic drive pump. The advantages of this pump include its ease of repair and maintenance as the pump parts can be accessed easily unlike the vertical pump type. Also, this pump has a low failure rate as well as a low noise level and smooth operation.

Figure: Horizontal Teflon lined magnetic drive pump.

Radial flow Teflon lined magnetic drive pump

This is the pump type in which the fluid exits the impeller after it rotates for 90o degrees relative to the suction line. Most of the Teflon lined magnetic drive pumps are of this design. Fluid is sucked through a horizontal suction line and leaves through a vertical exit flange. As such, the discharge end will be oriented perpendicular to the pump shaft. This type of pump design is recommended for use in applications where there is limited flow and where there is a need to increase discharge pressure. As such, the radial Teflon lined magnetic drive pump is a high-pressure and low-flow rate pump. Most of the pumps used in the oil refinery and chemical transportation are of this category.

Figure: Radial Teflon lined magnetic drive pump.

Axial flow Teflon lined magnetic drive pump

This the pump type designed such that the fluid enters the pump radially but leaves axially. Teflon lined magnetic drive pump manufacturers recommend this pump for use where there is very little pressure head but there is a huge flow rate.

Figure: Axial flow Teflon lined magnetic drive pump.

Mixed flow Teflon lined magnetic drive pump

This is the pump designed such that the flow of fluid mixes both radial and axial properties. This design balances axial and radial flow pumps. These pumps can operate at a large flow rate and with an increase in the head.

Figure: Mixed flow Teflon lined magnetic drive pump.

Applications of Teflon lined magnetic drive pump

- Teflon magnetic drive pumps are used in the transportation of acids and alkalis.

- They are used to pump food products such as milk, fats and beverage manufacturing products.

- These pumps are used in the manufacturing and transportation of chemicals.

- They are used in water treatment processes.

- Teflon lined magnetic drive pumps are used in oil refineries and the transportation of petrochemicals.

- They are used in pressure-boosting applications.

- They are used in crystallizing and cryogenic fluids.

Advantages of Teflon lined magnetic drive pumps

- This magnetic pump is free from corrosion.

- The pump is suitable for use in different applications making it versatile.

- The pump is durable if used according to the instructions given by the Teflon lined magnetic drive pump manufacturer.

- There are various types of this pump to suit various applications based on pressure requirements and flow rate.

- It is free from fluid leakage, unlike other pumps that use mechanical seals.

- It is of low maintenance requirements and reliable design. This is because the pump has few rotating parts reducing the probability of breakdown.

- No misalignment challenges. There is a small air gap between the motor and the magnet and pump. Since there is no physical contact, components misalignment cannot cause wear and breakdown.

- It reduces the risk of fines. Teflon lined magnetic drive pump manufacturers design the pump by adhering to strict safety and environmental regulations for different applications that involve flammable and hazardous fluids.

Disadvantages of Teflon lined magnetic drive pumps

- Applications of this pump are limited to handling solids. The pump is designed to best handle clean liquids since solids tend to stick to the magnets interfering with performance and causing pump failure.

- The application of this pump is limited to very hot fluids since they can damage the pump magnets.

Teflon lined magnetic drive pumps cannot run dry. As such, the liquid being pumped is used as the lubricant to prevent failure of bearing and other rotating components.

Troubleshooting Teflon lined magnetic drive pumps

Low fluid discharge

- The valve is closed. Open the valve.

- High system head. Reduce the system head or use a higher-rated pump.

- The pump is not primed. Prime the pump.

- Leakage through the suction pipe. Repair the suction pipe or replace it.

- Fluid viscosity is too high. Use the pump for the recommended fluid viscosity.

- Wrong motor rotation. Change the direction of motor rotation.

- Too high suction lift. Reduce the suction lift or use a higher-rated pump.

- Blockage in the pump or suction line. Open the pump as recommended by the Teflon lined magnetic drive pump and remove any material causing blockage.

Vibrations and or noise

- The motor and the pump are loosely connected. Tighten the motor and pump bolts and nuts to attain the torque recommended by the Teflon lined magnetic pump manufacturer.

- Impeller clogged by foreign materials. Remove the clogging materials.

Pump losses prime

- Leakage through foot valve or suction line. Check the foot valve and suction line and repair them as necessary.

- There is air or gas in the fluid. Remove air or gas in the fluid.

The pump consumes excess power

- Fluid viscosity and specific gravity are too high. Use the pump for the recommended fluid viscosity.

- There is excess fluid flow. Reduce fluid flow.

Low fluid pressure

- Motor speed is low. Increase the motor speed or use a motor with a higher speed.

- Wrong direction of motor rotation. Change the motor rotation.

- The impeller used has a small diameter. Use a pump with a larger impeller diameter.

Summary

A teflon lined magnetic drive pump is designed to operate using magnetic technology. This technology is such that the pump is not directly connected to the motor like commonly used pumps. The pump has two magnets the outer and the inner magnet. The outer magnet is driven by the electric motor so that it can drive the inner magnet through magnetic field forces. With the inner magnet rotating, the impeller then rotates creating a vacuum in the pump. The impeller rotation imparts kinetic energy to the fluid forcing it to proceed to the casing where pressure energy is added.

Teflon lined magnetic drive pump manufacturers produce various types of pumps such as horizontal pumps, vertical pumps, radial flow pumps, axial flow pumps, and mixed flow pumps among others. The applications of these pumps include oil refinery, chemicals, petrochemicals, hazardous fluids, water treatment, food and beverages, and pressure boosting among others. The advantages of using a Teflon lined magnetic drive pump are reliability, versatility, durability, and resistance to corrosion, low maintenance, leakage proof, low risks of fines, and no misalignment problems.