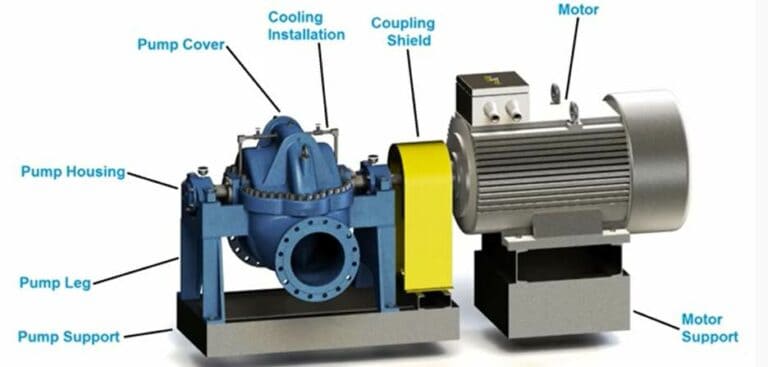

API610 BB3 Double Suction Split Case Pump

What is API610 BB3 double suction split case pump?

This is a heavy-duty pump designed for high-volume flow rates and high pressure. Due to the high volume flow rate, the pump has two inlets hence the name “double suction”. The two inlets help to balance the axial thrust on the impeller due to the large volume of liquid getting into the pump. The impellers are mounted along a center line between bearings on the pump shaft. API610 BB3 double suction split case pump manufacturers design these pumps for use in transporting large volumes of liquids over long distances and extreme heights as in oil and water pipelines. These pumps are available in more than one stage with double suction. The more the impeller stages the more the output pressure and thus the more the total head. This pump has its casing or housing split either radially or perpendicularly across the pump shaft. This split makes it easy to access internal parts of the pump for repair and maintenance.

Figure: API610 BB3 double suction split case pump

Components of API610 BB3 double suction split case pump

Electric motor

This is the part that provides power to the pump. This component works by converting electrical energy from the mains supply to mechanical energy. It outputs the mechanical energy as torque and angular speed through the motor shaft.

Coupling

This component is used to connect the motor shaft to the pump shaft at their ends to ensure continuous power transmission.

Pump shaft

This is the component of the pump that transmits power from the motor to the pump impellers. API610 BB3 double suction split case pump manufacturers produce this shaft from strong metallic materials like duplex stainless steel to ensure it can withstand the high torque needed to rotate the impellers at high speed.

Impellers

These are the components of the pump mounted on the pump shaft and meant to create a vacuum in the pump by rotating at a very speed. The impellers also help to increase liquid velocity by imparting kinetic energy to it.

Shaft sealing

These are mechanical seals or packing rings used to prevent leakage of the liquid from the pump.

Bearings

They are used to constrain the relative speed of the shaft and also reduce friction on the pump shaft.

Pump casing

This is an airtight housing that covers the internal parts of the pump. The casing also contains the inlet and outlet ports of the pump. API610 BB3 double suction split case pump manufacturers design the casing such that the kinetic energy of the liquid is changed to pressure energy as it moves through the casing. As such, the casing helps to transform the fluid from the impeller into a stable flow. The casing is split either radially or perpendicularly across the pump shaft into two parts. The two parts are connected together using bolts and nuts to enhance airtight pump.

Suction pipe, valve, and strainer

The suction pipe is used to convey the liquid from the storage into the pump. As such, it has one end connected to the storage tank and the other end connected to the pump. The suction valve is used to control the amount of fluid moving into the pump. The strainer is meant to filter out any foreign material from getting into the pump.

Delivery valve and pipe

The delivery valve is used to regulate the amount of fluid that leaves the pump into the pipeline. It has one end connected to the pump to convey fluid into the pipeline.

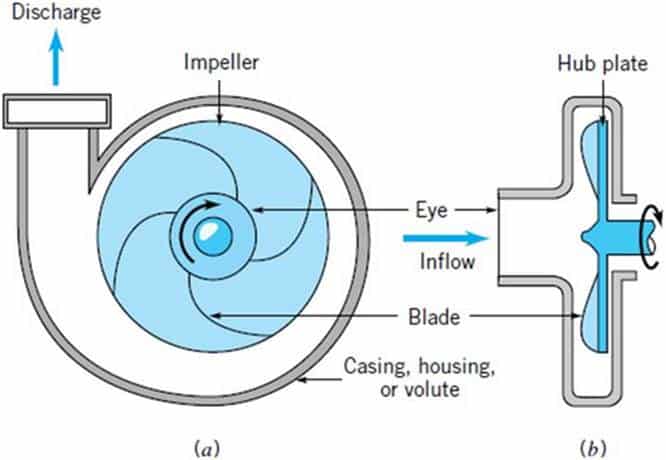

How does the API610 BB3 double suction split case pump work?

This pump operates by using the principle of pressure difference to draw liquid into the pump. When the pump is started, the electric motor shaft starts spinning at a very high speed. This motor power is transmitted to the pump through the shaft. As such, the pump shaft rotates at the same speed as motor shaft causing the pump impellers to spin. The rotation of the impellers inside the pump creates a vacuum that is, a state of low pressure relative to the atmospheric pressure on the surface of the liquid in the tank. Due to this pressure difference, the atmospheric pressure on the surface of the liquid forces the fluid into the pump via the suction pipe. As the liquid enters the pump, it meets the impeller spinning at high speed and thus it imparts kinetic energy to it. The fluid’s velocity increases as it progresses into the casing. In the casing the liquid velocity is reduced while pressure energy is increased. The high-pressure energy is responsible for moving the fluid to the required destination.

Figure: Working of API610 BB3 double suction split case pump

Types of API610 BB3 double suction split case pump

Self-priming API610 BB3 double suction split case pump

This is a pump designed with self-priming capabilities. Such pumps are installed partially or completely above the liquid level since they allow airflow into the suction pipe. This air must be removed before the pump starts operating. API610 BB3 double suction split case pump manufacturers design this pump to allow air removal before normal pumping operation starts. When the pump is primed, the air gets into the pump from the suction pipe, which combines with the liquid at the impeller. When the impeller rotates, it creates a vacuum. This vacuum forces the air to rise while the liquid moves down to the reservoir in the casing. The liquid is denser than the air and thus it flows by gravitational force into the impeller chamber. It then combines with the air remaining in the suction pipe. The process keeps repeating until all the air is removed and the pump is filled with the liquid needed for transportation. When the pump is turned off, it retains enough liquid to prime itself when it is started again.

Stainless steel API610 BB3 double suction split case pumps

This is a pump made of stainless steel material. Stainless steel material is safe in handling a wide range of products from to corrosive to flammable products like oil. These pumps are of high strength due to the high compressive and tensile strength associated with stainless steel material. As such, the pump is suitable for use in applications involving very high fluid flow rates and high pressure. In terms of temperature, this pump can work in both low and high temperatures such as in irrigation and steam power plants. The high-temperature capabilities are due to the low thermal expansion of stainless steel. The high strength of these pumps due to the stainless steel material makes them safe against impact due to falling objects. However, this pump is quite expensive relative to other pumps due to the high cost of stainless steel material.

Applications of API610 BB3 double suction split case pumps

- These pumps are used in the transportation of chemicals such as plastics, detergents, acids, and alkalis.

- They are used in long-distance and large-volume water supply applications.

- They are used in wastewater treatment and transportation.

- API610 BB3 double suction split case pumps are used in irrigation.

- They are used in oil refineries and transportation of oil products.

- These pumps are used as booster pumps in long-distance transportation.

- API610 BB3 double suction split case pumps are used in steam power plants to supply large volumes of water.

- They are used in paper and pulp manufacturing.

- They are used in offshore platforms.

- They are used in fluid injection and high-pressure services.

- They are used in heating, ventilation, and air-conditioning (HVAC) systems.

Advantages of API610 BB3 double suction split case pump

- They are of high strength enough to withstand high pressure and large mass flow rates.

- They can withstand high temperatures of 250 oC common in boilers and power plants.

- They are durable if used as per API610 BB3 double suction split case pump manufacturer’s instructions.

- They have high versatility as they are used in different industrial applications.

- API610 BB3 double suction split case pumps are resistant to corrosion.

- They have a lubricating system to reduce heating and friction on moving parts like bearings.

- They are of simple and compact design making them easier to install and repair.

- They are of various sizes allowing flow rates from 800 m3/h to 6000 m3/h depending on the demand.

Disadvantages of API610 BB3 double suction split case pumps

- These pumps use heavy metallic components making them very heavy in weight and more expensive relative to other pumps.

- They consume a lot of power as they run their heavy components meant to create large pressure energy.

- They suffer from cavitation especially if the NPSH is low.

- They are prone to wear especially when they operate in liquids containing solid particles.

- They need to be primed or have self-priming capabilities.

Troubleshooting API610 BB3 double suction split case pumps

The pump does not run or start

- Blown circuit breaker or fuse. Reset the circuit breaker, and replace the fuse as necessary.

- Foreign objects clogged the impeller. Disassemble the pump and remove the foreign materials.

- Broken or loose wiring. Tighten electrical connections.

- The motor has shorted out. Replace the motor.

- Improper wiring on the motor. Check the motor cables against the wiring diagram from API610 BB3 double suction split case pump manufacturer.

Pump does not prime

- Leakage through mechanical seals. Check mechanical seals and replace them.

- The casing does not have priming liquid. Fill the casing with priming liquid.

- Suction pipe leakage. Replace or repair the suction pipe.

- The discharge pipe is closed and so priming air cannot leave the pump. Open the discharge valve.

- The suction valve is closed. Open the valve.

- The strainer is blocked. Check the strainer and clean off blocking materials.

The pump does not develop pressure

- The pump is not primed. Prime the pump.

- Leakage through the suction line. Repair or replace the suction line as necessary.

- The discharge valve is closed. Open the discharge valve.

- Closed suction valve. Open the suction valve.

The pump makes excessive noise and vibrations

- Loose mounting plate. Tighten the mounting plate or foundation.

- Damaged impeller. Replace the impeller(s).

- Worn out bearings. Replace the bearings.

- Foreign materials in the pump. Open the pump and remove blocking materials.

- Too high suction lift. Lower the suction lift.

There is little to no discharge

- Too high head. Reduce the total head.

- The pump is not primed. Prime the pump.

- Plugged impeller. Clean off the impeller.

- Leakage through the suction line. Replace or repair the suction line.

- Closed or partially closed foot valve. Open the valve fully.

- The suction pipe is not fully submerged inside the liquid. Submerge the pipe fully in the liquid.

- The discharge valve is closed. Open the discharge valve.

- Wrong motor rotation. Change the direction of motor rotation.

Summary

API610 BB3 double suction split case pump is a heavy-duty pump meant for high heads and large flow rates of above 800 m3/h. These pumps have two inlets hence the name “double suction”. The two inlets help to balance the axial thrust forces on the pump impellers. API610 BB3 double suction split case pump manufacturers design the pump with more than two impeller. The more impellers help to create large pressure energy to support the large heads meant for this pump. The impellers are mounted between bearings on the pump shaft. The pump casing has two parts that is, the bottom and top part. The two are bolted together to ensure an air-tight pump. Splitting the casing makes it easier to access internal parts of the pump for repairs and maintenance.

API610 BB3 double suction split case pump manufacturers produce various types of pumps such as stainless steel pumps, and self-priming pumps among others. Applications of this pump include water supply and treatment, crude oil, chemicals, power plants, paper, and pulp among others. The advantages of this pump are versatility, high strength, corrosion resistance, high volume flow rate, durability, easy installation and repair, and simple and compact design.