API610 BB1 Double Suction Petrochemical Pump

What is API610 BB1 Double Suction Petrochemical Pump?

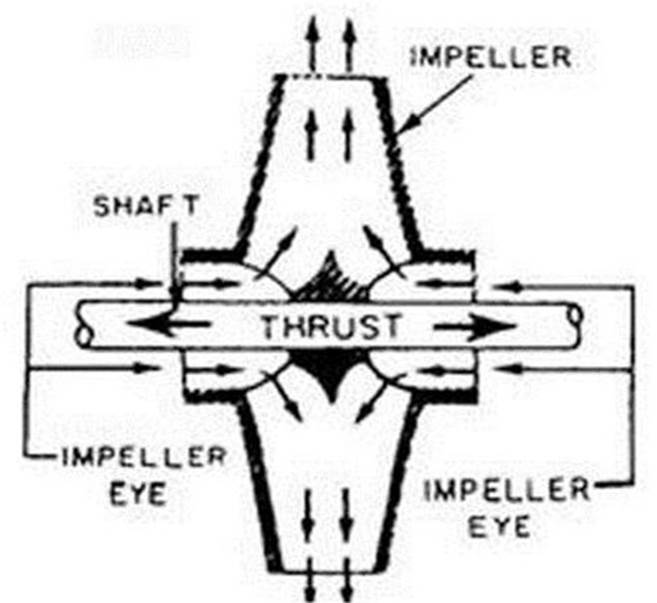

This is a centrifugal pump whose impeller is supported between two bearings. The impeller is mounted in a horizontal plane with the bearings. API610 BB1 double suction petrochemical pump manufacturers use this design to ensure better support to the impeller and enhance efficiency. As the name suggests ‘double suction”, this pump operates by drawing fluid from two inlets. Such a design gets rid of axial forces on the impeller allowing higher fluid flow relative to a pump with single suction. As such, API610 BBI double suction petrochemical pumps are less vulnerable to tear and wear emanating from axial thrust that happens when liquid enters the impeller. This type of pump is used in various applications among them crude oil pipelines, steam power plants, and chemical pipelines among others. The pump casing and hydraulics are designed to meet a wide range of pressure and temperature levels and high flow rate of around 3500 m3/h.

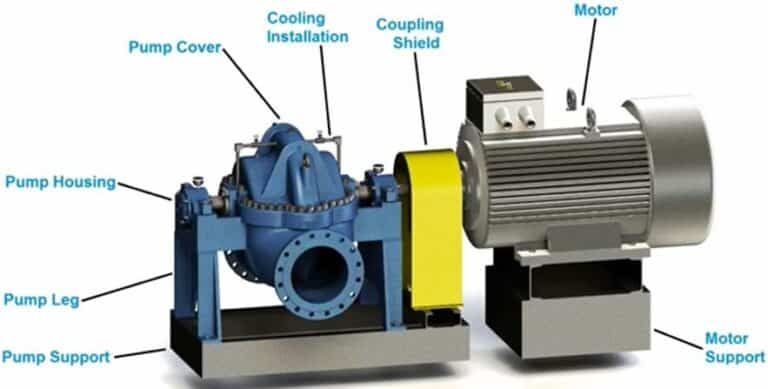

Figure: API610 BB1 double suction petrochemical pump

Components of API610 BB1 double suction petrochemical pump

Electric motor

This is the part of the pump that provides power to transport the fluid. The motor is connected to the pump via a short shaft. The shaft transmits mechanical energy from the motor to the pump in terms of torque and angular speed.

Pump shaft

This is a shaft that transmits power from the motor to the pump impeller. This shaft is connected to the motor shaft through another component known as coupling.

Impeller

This is the part of the API610 BB1 double suction petrochemical pump meant to create a vacuum in the pump when it rotates at very speed. This part is placed on a short shaft between two bearings on both sides inside the pump.

Coupling

This is the part that connects the motor shaft to the pump shaft.

Casing/housing

This is a shell that houses the internal parts of the pump. This housing helps to reduce fluid velocity while increasing its pressure energy to ensure it can move from the source to the required destination. API610 BB1 double suction petrochemical pump manufacturers produce the casing from strong metallic materials to ensure it can withstand fluid temperature and pressure as well as resist impact damage. The casing contains the inlet ports and outlet port.

Cooling system

This system contains pump lubricant meant to keep rotating parts like bearings well lubricated to avoid overheating and wearing out. The lubricant also helps to reduce friction on the moving parts thus enhancing efficiency.

Suction pipe and valve

The suction pipe is used to connect the pump to the tank containing the liquid to be transported. This pipe has one of its ends submerged in the tank and the other end is connected to the pump inlet port. This pipe is connected to an inlet valve that controls fluid flow from the tank to the pump. API610 BB1 double suction petrochemical pump manufacturers design the pump with a strainer that helps to eliminate unwanted solids flowing into the pump.

Discharge pipe and valve

The discharge pipe has two ends one connected to the pump and the other connected to the pipeline. This pipe is used to deliver fluid from the pump to the pipeline. A discharge valve is also included on the discharge end to control the amount of fluid that leaves the pump.

Figure: Components of an API610 BB1 double suction petrochemical pump

How does the API610 BB1 double suction petrochemical pump work?

The working principle of this pump is based on the pressure difference between the inside of the pump and on the surface of the liquid being pumped. The liquid is usually stored in a tank or another similar vessel. To start pumping, the pump is switched on. The pump impeller starts spinning at a very speed powered by the electric motor through its shaft. Due to the impeller rotation, a state of vacuum is created inside the pump. This vacuum causes fluid to move from its storage into the pump due to low pressure inside the pump relative to the atmospheric pressure in the tank. The liquid moves from the tank into the pump via the suction line into the impeller. The impeller rotating at high speed imparts high velocity to the fluid. The fluid then moves to the pump casing. In the casing, the fluid velocity is reduced while the pressure energy is increased. As such, the fluid gains a lot of pressure energy allowing it to move to the required destination.

Figure: Working of an API610 BB1 double suction petrochemical pump

Types API610 BB1 double suction petrochemical pump

Self-priming API610 BB1 double suction petrochemical pump

This is a pump designed to ensure it has start-up liquid inside the pump housing. The start-up liquid is needed to prime the pump. Operating the pump without the priming liquid can lead to certain problems that may lead to pump failure. API610 BB1 double suction petrochemical pump manufacturers design the pump to ensure all the air in the suction pipe is removed before pumping the air-free liquid.

When the pump is being primed, air from the suction line enters the pump and mixes with the liquid at the impeller. When the impeller rotates, a vacuum is created. This vacuum forces the air to move upwards and liquid to move downwards into the reservoir in the pump casing. The liquid is denser than the air and flows back into the impeller by gravitational force where it combines with the remaining air bubbles in the suction line. The process repeats until all the air is removed and the pump is filled with liquid. After the pump is filled with the liquid, the normal pumping process starts and the liquid is expelled through the discharge pipe.

Figure: Self-priming API610 BB1 double suction petrochemical pump.

Duplex stainless steel API610 BB1 double suction petrochemical pump

This is a pump made of stainless steel material. This pump is very strong and durable due to the good properties of stainless steel. Some of the superb properties associated with this material are corrosion resistance, high strength, and low thermal expansion. The corrosion resistance makes the pump suitable for use in transporting corrosive chemicals like soaps and detergents, drugs, fertilizers, explosives, paints, and epoxy resins among others. The high strength ensures the pump is safe against fractures that might arise from corrosion under stress or fatigue. It also makes the pump safe against high fluid pressure and impact damage. Low thermal expansion ensures the pump is resistant to heat when pumping hot fluids such as in steam power plants. The high strength of these pumps makes them operate at a very high flow rate of around 3500 m3/h.

Figure: Duplex stainless steel API610 BB1 double suction petrochemical pump.

Applications of API610 BB1 double suction petrochemical pump

- They are used in the transfer of manufacturing chemicals as plastics, colorants, detergents, and other related products from hydrocarbons.

- They are used in water injection oil fields to help recover more of the oil initially in place.

- They are used in the transportation of oil and fuel products for long distances.

- They are used in steam power plants and boiler-feed water supply.

- API610 BB1 double-suction petrochemical pumps are used in offshore platforms.

- These pumps are used in desalination plants and the supply of water.

- They are used in water treatment.

- They are used as booster pumps in long-distance transportation.

- API610 BB1 double suction pumps are in the paper and pulp industries.

- They are used in the transportation of hydrocarbons.

- They are used in oil refinery plants.

Advantages of API610 BB1 double suction petrochemical pumps

- These pumps are of high strength and thus they can operate at very high pressure.

- They can withstand high temperatures common in boilers and steam power plants.

- API610 BB1 double suction petrochemical pumps are resistant to corrosion, especially those made of stainless steel material.

- These pumps are durable especially if used according to the instructions given by the API610 BB1 double-suction petrochemical pump manufacturer.

- They are versatile. They can be used in different applications ranging from desalination to hydrocarbons and fuels.

- They use replaceable wear rings and sleeves.

- They have large impeller inlets allowing optimum suction of fluid.

- They have a cooling system to prevent overheating of bearing and rapid wear.

- API610 BB1 double-suction petrochemical pumps have a double-entry impeller that balances axial thrust as fluid enters the pump.

- They have smooth fluid flow free from pulsation, unlike positive displacement pumps.

- These pumps are available in a variety of materials depending on the area of applications and user’s preferences.

- They are of simple and compact design making repair maintenance easy.

Disadvantages of API610 BB1 double suction petrochemical pumps

- These pumps are large and heavy in weight. They need cranes to be lifted during installation.

- They are expensive relative to other pumps.

- They are prone to cavitation especially when the NPSH is too low.

- They consume a lot of energy due to the large impeller and shafts used to make the pump.

Troubleshooting API610 BB1 double suction petrochemical pumps

No or little discharge through the pump

- The pump is not primed. Prime the pump.

- Too high total head. Shorten the head and or suction.

- Plugged impeller. Open the pump and clean off materials clogging the impeller.

- Too high suction lift. Lower suction line.

- Leakage through the suction line. Replace or repair the suction line.

- Closed or partially opened foot valve. Open the valve fully.

- Damaged impeller. Replace the impeller.

- Small suction pipe. Replace it with one recommended by the API610 BB1 double-suction petrochemical pump manufacturer.

- Wiring fault on the motor. Check the motor wiring diagram and correct it as necessary.

- The discharge valve is closed. Open the discharge valve.

- O-rings or casing gasket leakage. Replace them as necessary.

Pump losing suction

- Leakage through suction. Replace or repair the suction line.

- Clogged strainer or foot valve. Unclog them as necessary.

Motor overheating and shutting off

- Motor voltage not matching power supply voltage. Ensure the motor wiring connection matches the power supply voltage as recommended by API610 BB1 double suction petrochemical pump manufacturer.

- Low motor voltage. Ensure the electrical wire connections are tight.

- The impeller rubbing on the pump casing or not turning freely. Disassemble the pump and remove materials sticking to the impeller or replace the impeller.

Leakage through the pump shaft

- Worn out mechanical seals. Replace the seals.

Excess noise or vibrations

- Loose foundation or mounting plate. Reinforce the base or mounting plate.

- Foreign materials in the pump. Disassemble the pump and remove all foreign materials from the pump.

- Damaged impeller. Replace the impeller.

- Worn out bearings. Replace the bearings.

Summary

API610 BB1 double suction petrochemical pump is a heavy-duty pump designed with two impeller support bearings on both sides. This pump guarantees better impeller support that leads to high efficiency and less noise. The pump draws fluid into the pump through two inlets hence the name “double suction”. By having two inlets, the pump is able to eliminate axial forces on the impeller eye leading to a higher fluid flow rate compared to a single suction pump. This design also reduces wear and tear on the impeller.

API610 BB1 double suction petrochemical pump manufacturers design various types of pumps such as duplex stainless steel pumps and self-priming pumps among others. Applications of this pump include crude oil, hydrocarbons, desalination, oil refinery, and chemicals, among others. The advantages of using this pump are versatility, long service life, and resistance to corrosion, large volume flow rate, high strength, low thermal expansion, simple and compact design, and easy installation, repair, and maintenance.