What is a vertical multistage water transfer pump?

A vertical multistage water transfer pump is a centrifugal water pump that operates using two or more impellers. The pump is installed in vertical orientation due to small floor space. However, it needs significant headroom for installation. Vertical multistage water transfer pump manufacturer’s mount the impellers on one shaft or different shafts. However, most pumps use one shaft to mount all the impellers. The impellers are arranged in series along the pump shaft. Each impeller forms a water flow stage. For each stage, the pressure energy increases. As such, the more the number of impellers, the more the pressure energy for a given pump. Vertical multistage water transfer pumps are suitable when high pressure is required, which single-stage vertical pumps cannot achieve. They do have high flow rates, such as 2000 m3/h. These pumps are suitable for pumping water in construction, municipal water supply, and irrigation among others.

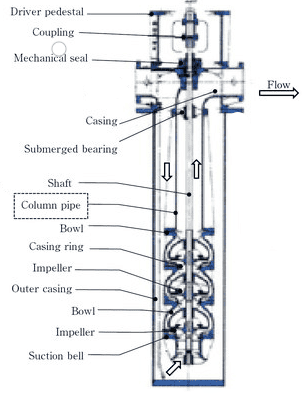

Figure: Vertical multistage water transfer pump

Components of a vertical multistage water transfer pump

Electric motor

As the name suggests, an electric motor operates by using electricity. The motor is the only source of power for your vertical multistage water transfer pump. However, there are other pumps that operate using diesel engine. Electric motor operate by converting electrical energy from the mains supply to mechanical energy. The mechanical energy is transferred from the electrical motor to the pump using the motor shaft and pump shaft.

Pump shaft

Vertical multistage water transfer pump manufacturers machine the shaft from high-strength metallic materials such as carbon steel and stainless steel to make sure it is strong to withstand the torque needed by the pump. The pump shaft is the one that transmits power from the electric motor to the pump. The motor also has its shaft. A coupling element connects the two shafts.

Impellers

Impellers are rotating discs with vanes. They are installed in series on the pump shaft. They work to transfer power from the electric motor to the pump by rotating at high speed. The high speed provides kinetic energy to the water.

Casing

The casing is an external component of the pump and contains the pump’s suction and discharge ports. The casing also helps to mount the pump firmly where it is installed. Vertical multistage water transfer pump manufacturers design the casing such that the water flow area increases as the water moves out of each impeller. By increasing the flow area, the water flow velocity is reduced, and thus pressure increases. The exact process happens for each stage or impeller and thus leads to high discharge pressure as the water exits via the discharge port.

Strainer, suction valve, and pipe

The strainer is a component designed by vertical multistage water transfer pump manufacturers to help filter out unwanted solids in the water. The suction pipe connects the pump to the water tank, through which water flows into the pump. The suction valve helps control the amount of water entering the pump and prevents the backflow of water from the pump into the storage tank.

Discharge valve and pipe

The discharge valve helps you to control the amount of water leaving the pump into the piping system. The discharge pipe conveys water from the pump to the piping system for transportation to the required location.

Bearings

Bearings are used to support water loads imposed on the impellers, mass of the shaft and impellers, and loads due to shaft and coupling.

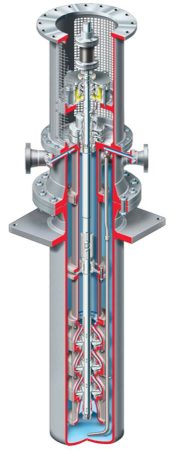

Figure: Components of a vertical multistage water transfer pump.

How does a vertical multistage water transfer pump work?

A vertical multistage water transfer pump operates, pushing the water from its storage into the piping system. Atmospheric pressure forces the water from its storage tank into the pump when a vacuum is created inside. The vacuum is created by first turning the pump on. Due to the vacuum, atmospheric pressure on the water’s surface pushes the water into the pump. As such, the pump impellers rotate at high speed, causing the vacuum. Due to the high velocity of the impellers, the water gains more kinetic energy and velocity as it enters the first impellers. The pump casing is designed to increase the flow area as the water moves out of each impeller. As such, the water pressure increases while the flow velocity reduces. The process continues to the next stage, or impeller, creating more pressure energy. The water keeps gaining more pressure energy until it leaves the last impeller.

Types of vertical multistage water transfer pumps

Self-priming vertical multistage water transfer pump

This is the type of pump that is capable of priming itself. Pump priming means filling the pump with water to remove air bubbles in the pump and the suction pipe. With such air bubbles in the pump, the atmospheric pressure will not create the needed force to push the water into the pump, and thus no water flow. However, this pump is meant best for clean water without solid particles. Unlike other pumps that need to be primed manually, vertical multistage water transfer pump manufacturers produce this pump with features that enhance self-priming capabilities.

This type of pump is best for applications where it is impossible to supply the inlet with water via gravity. Such applications include where the pump is installed above the water tank and thus requires a suction lift. It is also applicable when the suction conditions are difficult, like in a long pipe. The priming system and the pump work together to complete the priming process. The priming process helps to expel air out of the pump and out of the suction pipe into the discharge port. The actual water pumping process starts once all the air is removed from the pump. The pump is highly reliable and can achieve high head and flow rates.

Diesel-operated vertical multistage water transfer pump

Diesel vertical multistage water transfer pump operates by using IC engine. This type of pump is best suitable for use where electricity is unavailable. It is a highly convenient and energy-efficient type of pump. It is easy to operate and has a high range of head and flow rates of 200 m and 1400 m3/h.

Figure: Diesel operated vertical multistage water transfer pump.

Submersible vertical multistage water transfer pump

Submersible type of pump operates while immersed in the water. Vertical multistage water transfer pumps manufacturer produce various types of this pump to cater to multiple fluids such as clean water, wastewater or dirty water, or water containing heavy-duty particles. The submersible pump meant for solid particles comes with a shredding mechanism. The mechanism helps to cut off large solid particles before they are transported. It also helps prevent the pump from blockage due to such large solids. The pump is designed with a float switch allowing the operator to turn it on and off without the need to go deep in the water tank or well. This type of pump is powered using an electric motor. Both the motor and pump are hermetically sealed to prevent water from entering the electrical components. An extended power cable from the pump to the mains supply transmits power to the pump.

Figure: Vertical multistage water transfer pump.

Applications of vertical multistage water transfer pump

- These pumps are used in energy power plants to supply water for cooling.

- They are used in mining applications.

- Vertical multistage water transfer pumps provide the water needed in firefighting applications.

- They are used in agriculture to provide the required water for irrigation.

- They are used in desalination and water treatment plants.

- Vertical multistage water transfer pumps are used in deep wells to lift water for domestic or commercial use.

- They are used in dewatering to clear floods.

- These pumps are used in construction to supply water.

- It is used in a high-rise building to lift water from the ground level to the top rooms.

Advantages of vertical multistage water transfer pumps

- These pumps have a smaller footprint. The pump takes up less floor space, allowing it to fit in tighter areas, unlike horizontal pumps that take up ample floor space. As such, these pumps are ubiquitous in areas with limited space, which is a crucial factor to consider when selecting pumps.

- These pumps have a high flow rate and can meet large flow heads.

- They have significant efficiencies. Vertical multistage water transfer pump manufacturers design the impellers with small clearances and diameters, allowing better performance and high efficiency.

- These pumps produce high hydraulic pressure energy due to having more than one impeller. At each impeller, water pressure is increased.

- They have smooth water flow.

- They are versatile in size.

Disadvantages of multistage split case pump

- These pumps need significant headroom for installation.

- Repair and maintenance become challenging since most pumps are installed high above or below the ground.

- It is challenging to balance the hydraulic thrust on vertical multistage water transfer pumps due to the overhang design, mainly where the pump works on high suction and pressure.

- They are expensive relative to the single stage pumps.

Troubleshooting vertical multistage water transfer pumps

The pump produces no water

- No power on the motor. Check motor power cables are correctly and firmly connected to the motor.

- Wrong direction of motor rotation. Check the direction of motor shaft rotation. It should match the arrow of rotation indicated on the pump casing.

- Clogged impeller. Open the pump according to the vertical multistage water transfer pump manufacturer’s instructions and remove any material blocking the impeller.

- Closed discharge valve. Open the discharge valve.

- Closed suction valve. Open the suction valve.

- The pump is not primed. Prime the pump fully.

- The suction lift is too high. Lower the pump towards the tank or increase the water level.

- Clogged filter. Clean off materials blocking the filter.

Low water flow

- Leakage through the suction line. Check the suction pipe and make repairs or replace it.

- The discharge valve is partially open. Open the discharge valve fully.

- The suction valve is partially open. Open the valve fully.

- Foreign materials in the pump. Disassemble the pump and clean off blocking materials.

Pump bearings failed

- The shaft or coupling misalignment. Align the shaft and coupling properly.

- The bearing covers are too tight. Loosen the covers.

- No lubrication in the bearings. Lubricate the bearings.

- The bearings are worn out. Replace the bearings with new ones.

Water leakage through the pump

- Mechanical seals are worn out. Replace the seals.

- Loose connection between the pump and the piping system. Tighten the connecting bolts and nuts firmly.

The pump vibrates a lot

- The impeller is partially clogged. Clean off foreign materials.

- Defective or worn impeller. Replace the impeller.

- Shaft or coupling misaligned. Align shaft/coupling properly.

- The pump is not firmly tightened to the base. Tighten the pump base support.

Summary

A vertical multistage water transfer pump is a type of centrifugal water pump installed in a vertical orientation. The pump occupies a small floor space; thus, it is suitable for installation in areas with limited space. The pump operates by creating a vacuum inside. The vacuum is created when pump impellers rotate at high speed. This vacuum helps to draw water into the pump. The water gets more kinetic energy when it enters the pump. The kinetic energy is then converted to pressure energy. Vertical multistage water transfer pump manufacturers design this pump with more than one impeller. Each impeller forms a stage. The impellers are arranged in series from the suction to the discharge end. At each stage, water pressure increases until the water leaves the final stage. These pumps are potent and thus suitable for high heads and significant flow rates.

Vertical multistage water transfer pump manufacturers produce various types of this pump, such as submersible, self-priming, and diesel pumps. This pump can be used in irrigation, high-rise building, firefighting, dewatering, mining, power plants, and municipal, domestic, and water treatment. Advantages of using this pump include small space, versatility in size, reliability, highly efficient, easy to repair, high flow rate, and pressure energy.