Aodd Pump

Working principle of air operated double diaphragm pump

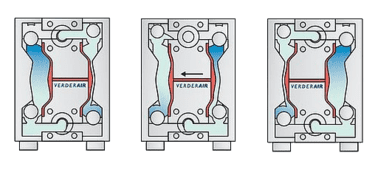

The compressed air distribution system functions to regulate the flow of air within the pump mechanism. Initially, it directs compressed air to the rear of diaphragm A, causing it to move away from the central section. Subsequently, diaphragm A exerts pressure on the liquid chamber, resulting in the expulsion of liquid from chamber A. Concurrently, the compressed air behind chamber B is released into the atmosphere, creating a vacuum effect. This action forces the inlet ball valve within chamber B to disengage from its seat, allowing the chamber to be replenished with liquid.

Once pressurized diaphragm A completes its stroke, the air distribution system vents the air from the chamber, and compressed air is redirected to the rear of diaphragm B. The application of compressed air pushes diaphragm B away from the pump body’s central axis, causing the shaft to draw diaphragm A toward the center. Simultaneously, the volume of chamber B decreases, resulting in the displacement of the discharge ball valve from its seat, and the fluid is pumped into the discharge port.

Upon the completion of this stroke, the air valve directs air back to the rear of diaphragm A, initiating the cycle anew.

Figure: suction and discharge cycle of air operated double diaphragm pump.

Characteristic of Air operated double diaphragm pump

Positive Displacement: It operates as a positive displacement pump, ensuring consistent flow rates regardless of variations in pressure.

Leak-Free: Air operated double diaphragm pumps are designed to be leak-free, minimizing the risk of fluid leakage and environmental contamination.

High Viscosity Handling: Capable of efficiently handling high viscosity fluids, making it versatile for various applications.

Suitable for Hazardous Liquids: Well-suited for transferring flammable, toxic, and corrosive liquids, enhancing safety in challenging environments.

High Efficiency: Achieves a high level of efficiency, with some models capable of reaching up to 97% efficiency.

Self-Priming: Exhibits excellent self-priming ability, allowing it to start pumping quickly even when the pump is not fully filled with liquid.

Oil-Lubricated Components: Internal components are often suspended in oil, reducing wear and extending the pump’s service life.

Great Idling Properties: Performs effectively even when idling or running with minimal load, maintaining reliability in various operating conditions.

Medical Applications: Can be employed in medical equipment, such as artificial heart devices, highlighting its precision and safety features.

High Pressure Capability: Suitable for handling high exhaust pressures, with some models capable of handling pressures up to 1200 bars.

Good Suction Lift: Effective for low flow rates and low-pressure applications, providing flexibility in fluid transfer tasks.

Gentle Handling: The pump’s design allows for gentle spinning, making it suitable for shear-sensitive media that may be damaged by aggressive pumping methods.

Submersible Operation: Can operate in submerged conditions, expanding its utility in various industrial and environmental settings.

Technology Parameters:

Flow:0-30m3/h;

Head:0-50m;

Calibre:10-100mm;

Temperature:-15-+120℃;

Pressure:0.1-0.7MPa;

Self-priming high:5-7m。

| Series | Type | Inlet diameter(mm) | Capacity(m3/h) | Head(m) | Suction stroke(m) | Max diameter of granules allowed(mm) | Max available air pressure(Kgf/cm2) |

| NPY | NP10 | 10 | 0.8 | 50 | 5 | 1 | 7 |

| NP15 | 15 | 1 | 50 | 5 | 1 | 7 | |

| NP25 | 25 | 2.4 | 50 | 7 | 2.5 | 7 | |

| NP40 | 40 | 8 | 50 | 7 | 4.5 | 7 | |

| NP50 | 50 | 12 | 50 | 7 | 8 | 7 | |

| NP65 | 65 | 16 | 50 | 7 | 8 | 7 | |

| NP80 | 80 | 24 | 50 | 7 | 10 | 7 | |

| NP100 | 100 | 30 | 50 | 7 | 10 | 7 |