Centrifugal Monoblock Water Pump

Components of a centrifugal Monoblock water pump

Motor

This component provides power to run the pump. The motor must be connected to the power supply for the pump to run. It converts electrical energy from the mains supply into mechanical energy. The mechanical energy is needed to run the centrifugal Monoblock pump for water to move to your destination.

Shaft

Centrifugal Monoblock water pump manufacturers machine the shaft from high-strength steel materials to make it able to withstand the high power needed to operate your pump every day. The shaft is a solid mechanical component that transmits mechanical power from the motor into the pump. A bearing on both ends supports the shaft.

Bearings

The bearings are mounted on both ends of the shaft that is on the motor and on the pump. The bearings support the shaft, impellers, and hydraulic loads due to water. The bearings also help reduce friction when the shaft is rotating. Also, by having bearings, the axial shaft movement and lateral deflections are kept within manageable limits.

Impeller

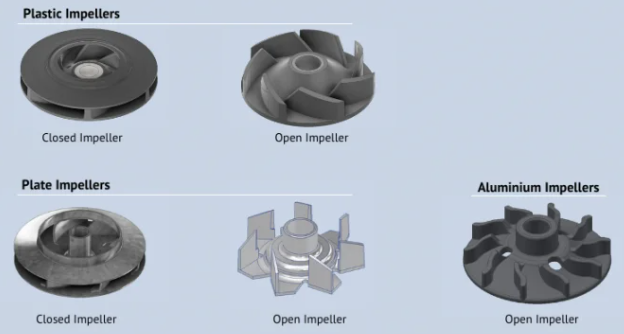

The impeller is a disc with curved vanes. It transfers power from the rotating shaft to the fluid being pumped as the water enters the pump. The water enters the pump and meets the impeller at its center, also known as the eye impeller. Two main types of impellers are the open impeller and the closed impeller.

The open impeller is designed with the blades open on both sides. This impeller does not have a protective cover. It is primarily used in small centrifugal Monoblock water pumps to avoid much stress. The closed impeller is wholly covered on its front end. It offers maximum resistance, and it is prevalent on large-sized water pumps. The closed impeller is preferred because of its ability to reduce axial thrust, which helps enhance bearing service life.

Figure: Centrifugal Monoblock water pump impellers.

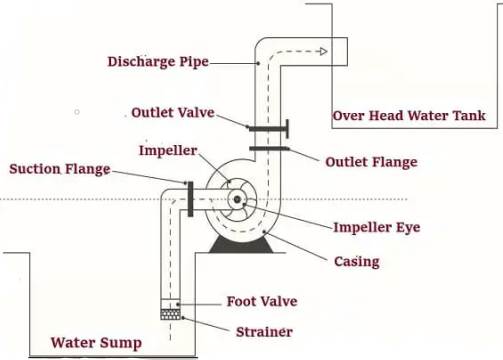

Casing

The pump casing is an external shell meant to seal off the pump interior from the outside. Centrifugal Monoblock water pump manufacturers design the casing depending on the type of pump. The work of the casing is to prevent water leakage and keep pressure by sealing the pump interior against the atmosphere. The casing surrounds the pump impeller. The “pump” is contained in the casing. A centrifugal Monoblock water pump casing is for:

- Keeping water pressure in check.

- Allowing installation and removal of the impeller.

- Provide structural support or a structural link to support the pump.

- Keep the pump and motor aligned.

Three main types of casing are the volute casing, vortex casing, and casing with guide blades.

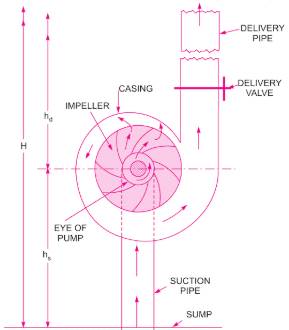

Volute casing. This type of casing has a continuous rise in the flow area. The fluid flow velocity reduces as the flow area increases. The water pressure through the casing increases as the fluid speed decreases. The volute casing is the most common type of casing. It is mainly used in single-stage centrifugal Monoblock water pumps.

Figure: Volute casing.

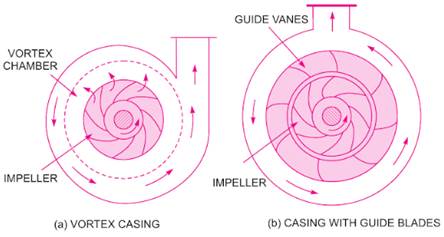

Vortex casing. This casing is designed with a circular chamber between the impeller and the casing. This casing has the advantage of improving pump efficiency by reducing production eddies during water flow.

Casing with guide blades. A centrifugal Monoblock water pump with a casing with guide blades has an impeller encircled by guide blades. The guide blades are attached to a diffuser ring. Centrifugal Monoblock water pump manufacturers design the guide vanes such that water leaves the impeller and enters the guides without causing shock. The guide vane’s area increases as the water flows to the discharge. This helps to reduce water velocity to increase pressure energy. Most pumps are designed such that the impeller and casing remain concentric.

Figure: Vortex casing and casing with guide blades.

Suction pipe with filter and valve

The suction pipe connects the source of water and the pump. The suction valve regulates the amount of water entering the pump. The strainer filters solid particles contained in the water.

Discharge pipe and valve

The discharge pipe has one end connected to the pump and the other connected to the pipe network. The discharge pipe conveys water from the pump into the piping system. The discharge valve regulates the water leaving the pump into the pipe network.

Figure: Components of a centrifugal Monoblock water pump.

Types of centrifugal Monoblock water pump

Self-priming centrifugal Monoblock water pump

A self-priming centrifugal Monoblock water pump is a type of pump that is capable of priming itself. This pump is very advantageous in that it relieves the pump operator of filling the pump with water to remove air in the water. When the impeller rotates, it creates a vacuum in the pump. This vacuum draws air into the pump from the suction line. At the same time, the pump creates a ring of water on the pump casing. As such, an effective gas-tight seal is formed that stops air from returning from the discharge port into the suction pipe.

Bubbles of air are trapped in the water on the impeller vanes and then transferred to the discharge port. At the discharge end, the air leaves, and the water returns to the pump reservoir via gravitational force. The water rises the suction pipe slowly as any air is expelled. The process keeps going on until all the air in the pump is replaced by water. Once all the air is removed, the actual pumping process starts, and water is discharged into the piping system. Centrifugal Monoblock water pump manufacturers design the pump such that when it is shut off, a priming chamber retains water for the pump to prime when it is started again.

Figure: Self-priming centrifugal Monoblock water pump.

Submersible centrifugal Monoblock water pump

Submersible centrifugal Monoblock water pump operates while submerged in water. The pump is designed so that the motor and casing are enclosed in an air-tight enclosure that prevents water entrance into the motor. This design helps prevent water from getting into the motor’s electrical components and causing damage. The pump is suitable for use in deep wells that would not be possible with standard centrifugal Monoblock water pumps. The pump has a long power cable allowing the operator to turn it on and off without getting into the deep well. Centrifugal Monoblock water pump manufacturers design the pump with sensors that notify the operator in case of any technical problem.

Figure: Submersible centrifugal Monoblock water pump.