Self Priming Pump

What is a Self Priming Pump?

A self priming pump is a water pump that can draw the water from the source without depending on any external energy. A self-primatic device starts working automatically as soon as it comes in contact with the liquid and does not require any specific type of energy, such as electricity or fuel, for its operation.

This saves time and energy considerably. It derives its name from the fact that it draws water by its own force rather than using other power.

REQUEST A QUOTE FOR MORE DETAILS

How Does a Self Priming Pump Work?

To answer this question, first, we need to know what differentiates a non-self priming pump from a self priming one. Unlike a non-self priming pump, a self-priming pump can draw water by its own force without any external energy supply.

Let us take an example of a bucket and a tap that stands next to it. Typically, we will open the faucet and let the water flow through this path, i.e., from tap to bucket. Both these actions need external energy. Firstly, we need to turn on the tap, and then we need to lift or hold down the bucket for its content (water) to reach its destination (the bucket).

In the case of a self-priming pump, as soon as it gets in contact with water, it starts working automatically following the action-reaction principle. It does not require any external energy to start working.

Self Priming Pump Types

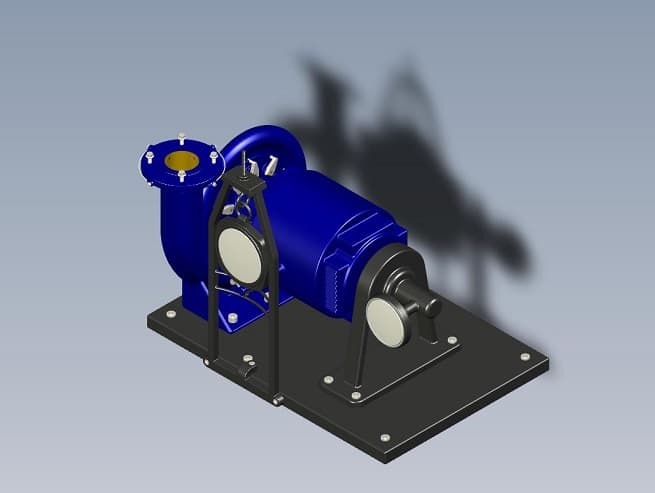

There are different self priming pumps such as Self Priming Water Pumps, Self Priming Monoblock Pumps, Self Priming Centrifugal Pumps, etc.

Self Priming Water Pump: A water pump is used to transfer liquids and fluids like water from a lower place to a higher place with the help of its own power/force without depending on any external power or force.

There are two main components in it. The suction chamber has a wide-open space to let water flow inside it. After the water enters this, some valves are closed, separating the chamber into two parts, i.e., upper and lower chambers.

This upper chamber has an opening at its bottom while a pump impeller is attached to it, which turns around with a shaft fitted in bearings. The function of this pump impeller is to push down/suck up all the water from the lower chamber quickly and send it outside through delivery piping using centrifugal force.

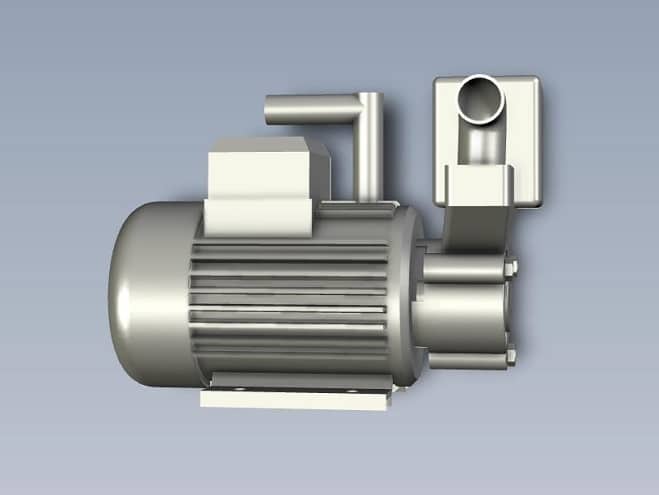

Self Priming Monoblock Pump: A self-priming monoblock pump connects itself directly to the suction side of the main pump like mud pumps or sewage pumps used in heavy industries. It helps give off the pump station piping system to take suction from variable depths, pressures, capacities, and specific gravities.

Unlike a normal suction pump, it can easily handle light solids about 10-12 mesh size, whereas non self priming pumps will choke due to heavy solids. This is one of the most important benefits of using this type of pump.

Self Priming Centrifugal Pump: A centrifugal pump is similar to a turbine in some respects. As with turbines, fluid enters the eye of the impeller and moves toward the diffuser side. But on leaving, fluid spins around inside the volute casing before exiting through an outlet near its base.

Fluid path: Inlet (suction), eye, diffuser, volute. In short, the fluid leaving the impeller goes from low pressure to high pressure and is done so by spinning it inside a casing.

Self Priming Drill Pump: This type of pump has been specially designed for drilling rigs and other oil production operations. It is necessary to circulate mud and other liquids under tremendous pressure and often at considerable depths below surface level.

It can maintain its prime even after temporary shutdowns of only seconds or minutes. It consists of a small electric motor that drives an eccentric screw that forces the liquid through a conduit system into the drill bit area.

The Priming System provides an automatic refill capability during shutdowns as short as 30 seconds. The pump will deliver approximately 40 GPM at 100 psi.

Self Priming Regenerative Pump: This pump is designed to lift water and other liquids from a lower level to a higher level. It consists of two chambers – the suction chamber and the delivery chamber. The suction chamber has a wide-open space to let water flow inside it.

After the water enters this, some valves are closed, which separates the chamber into two parts, i.e., upper chamber (suction) iii) lower chamber (delivery). The upper chamber has an opening at its bottom while a pump impeller is attached on top of it, which turns around with a shaft fitted in bearings.

The function of this pump impeller is to push down/suck up all the liquid from the lower chamber quickly and send it outside through delivery piping using centrifugal force.

Advantages of Self Priming Pump

- It requires only a minimum head to start the liquid flow, even if its capacity is large.

- The prime mover can be placed in any convenient location.

- When the prime mover stops, this pump gives a subjective result with a slight reduction in discharge pressure.

- You don’t have to provide a priming suction as for other pumps.

- It runs at low speeds leading to less noise and wears and tear.

- While submerged, no air pockets form inside the pump.

- Capable of handling non-compressible liquids.

- Less chance of cavitation.

- Less chance of stalling.

- It can be used to pump dirty liquids.

Disadvantages of Self Priming Pump

- Leakage on the delivery side.

- It is suitable only for pumping clean and non-compressible fluids, not gases.

- The shaft seals must be kept tight to avoid leakage.

- The pumps should never be primed with gas or allowed to suck air.

- When suction pressure is applied, a vacuum develops at the eye of the impeller, which may cause vaporization/cavitation.

- Due to heavy fluid pressures, they are difficult to start.

- If valves on both sides get stuck open, there will be no flow through the pump.

- It is suitable only for clean and non-contaminated liquids.

- It must be carefully primed to avoid the water hammer effect.

- The starting torque is very high.

- The most critical disadvantage of self-priming pumps is that they need a great head to start the liquid flow, even when the capacity is large.

Self Priming Pump Applications

Most water pumps require some form of prime (mechanical or hydraulic) to start working and produce flow. However, the self priming pump is the opposite.

They can generate their own prime, which means these pumps can handle fluids with very low specific gravity like raw waters with chlorine gas content without any problem as they don’t require an external source of prime (pressure).

By now, you may be wondering how such a thing can be possible. Well, the secret lies in their inlet and outlet ports, which are symmetrical (close to each other), which means water can fill up inside the volute by its own weight.

When there is enough prime inside to overcome resistance caused by fluids in the impeller area, the pump’s shaft starts rotating, and the flow rate increases significantly. This is because the pump cannot drain the fluid that has entered into it fast enough due to the close proximity of inlet and outlet ports, resulting in very high viscous drag.

Self priming pumps are most commonly used in industries where they are required to handle raw water with high chlorine content or solid particles. Since they can prime themselves, no external prime source is needed.

Troubleshooting Tips for Self Priming Pumps

Here are some general troubleshooting steps that self priming pump manufacturers suggest that should be followed for all types of pumps:

- Disconnect power and rotate the pump shaft to ensure it is not stuck. If there’s no obstruction (stuck) inside and the impeller rotates freely, the problem may lie with the motor or mechanical seal system.

- Check if the flow rate is high enough for the motor to work continuously without tripping off the circuit breaker. If there is not enough flow available through the pump, increase its speed as much as possible (at this point, you should also check that raw water has all sorts of possible chemicals like chlorine gas).

Also, ensure that maximum lift height does not exceed rated values; otherwise, it will cause motor overheating, leading to motor burnouts.

- Now, set your multimeter to Ohms scale and connect one of its probes on motor terminals. Now slowly turn the pump’s shaft and watch the multimeter as it may show a shallow reading for a moment. This is because there will be some resistance in electric lines due to which current flow is being stopped momentarily.

This will not cause any problems as such, but if you have set up your circuit breaker so that it hardly trips at normal load requirements, given high enough draw may burn out the motor permanently (so make sure your circuit breaker can handle 2-3 times extra load than required without tripping off or reducing speed).

- If everything seems all right until here (i.e., the pump can run continuously without any issues), it means either of the following possibilities may be the cause of your problem:

- The pump’s impeller is partially clogged with solid particles.

- There is some obstruction in the inlet piping system (the pump needs a high flow rate to overcome this obstruction).

- If you are sure that the impeller looks fine even after rotating it manually, the next step will be to take out the motor & mechanical seal assembly from the pump’s case and carefully check its condition.

You can do this by following the instructions given in your Pump User Guide unless there is any special procedure that you need to follow while removing the cover on your pump.

Summary

A self-priming pump is a positive displacement pump that can work without requiring any external power source. It takes the energy from the liquid being pumped and uses it to generate pressure to get its job done.

The main advantages of this kind of pump are reliability, long service life, low maintenance cost, and high efficiency. In addition, self priming water pumps have many types, such as self priming monoblock pumps, self priming centrifugal pumps, self prime drill pumps, and regenerative self prime pumps.

Disadvantages include greater size than other kinds of similar capacity pumps and relatively higher initial costs for installation because they require no external power supply when operating properly on level ground.

The self priming pump is one of the pumps that can be used for various purposes. It has many advantages, but it also has disadvantages which you should consider before using this type of pump.