Stainless Steel Vertical Multistage Pump

What is stainless steel vertical multistage pump?

Stainless steel vertical multistage pump is a centrifugal pump installed in the vertical orientation. This pump has specific characteristics of more than one impeller. The impellers help to create the kinetic energy needed to move the liquid from the storage into the pump. The more impellers, the more kinetic energy, and pressure energy. This type of pump is potent for moving fluid for a high head. Stainless steel vertical multistage pump manufacturers design this pump using metallic steel material to make it strong in terms of withstanding high pressure and high temperature and also be resistant to corrosion. The use of steel makes the pump have a long service life and be economical. Stainless steel vertical multistage pump applications are broad, like water supply, water boreholes, sewage treatment, chemicals, and mining, among others.

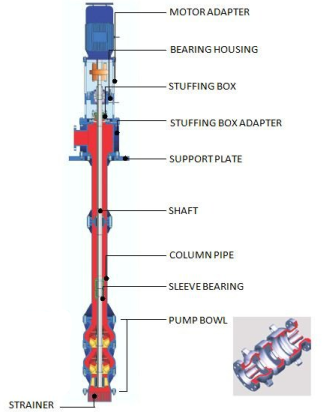

Figure: Stainless steel vertical multistage pump

Components of a stainless steel vertical multistage pump

Electric motor

The electric motor is the component that provides the power that operates the pump. The motor will ensure that your pump can deliver the fluid to the intended destination. Stainless steel vertical multistage pump manufacturers design the pump for a motor to serve a certain head. The more the head, the more powerful the motor should be.

Pump shaft

The pump shaft connects the motor to the pump. Power from the motor is transmitted through this shaft. The shaft carries the kinetic energy needed to rotate the impellers.

Impeller

Using impellers in a stainless steel vertical multistage pump aims to transfer mechanical energy from the motor to the fluid being pumped. The impeller is a component designed with vanes that, when the pump starts running, rotates at high speed relative to the motor shaft. The fluid gains much kinetic energy as it proceeds along the pump from one impeller to the next one.

Casing

The casing is an external component of the pump that covers internal parts. It helps seal off the pump interior to the outside against atmospheric pressure and prevent fluid leakage. The casing helps to increase pressure energy on the fluid as the fluid moves from the impellers to the discharge port. Stainless steel vertical multistage pump manufacturers design the pump so that the fluid pressure increases at every stage until the media leaves the pump.

Strainer

The strainer is a component that helps the pump to filter off dirt and other unwanted particles from entering the pump. Using the filter helps prevent pump blockage from such particles and reduces the chances of downtime and unnecessary repairs and maintenance.

Figure: Components of a stainless steel vertical multistage pump

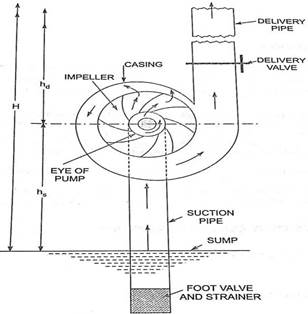

How does a stainless steel vertical multistage pump work?

A stainless steel vertical multistage pump is a type of centrifugal pump. As such, this pump employs centrifugal force to impart kinetic energy to the fluid. The fluid flow starts when the pump is turned on. The pump turns on when there is electrical power supply on the motor. The presence of power on the motor causes the motor shaft to rotate at high speed. This motor shaft is connected to the pump shaft via a coupling. The pump shaft then transmits rotary power to the pump impellers. The impellers then rotate at the same speed as the motor shaft. When the impeller rotates, a vacuum is created in the pump. The vacuum forces the fluid to move from the sump into the impeller’s eye due to pressure difference.

The fluid moves into the pump at sheer speed/kinetic energy. The fluid absorbs more power in the first impeller/stage and proceeds to the next impeller through the casing; as the liquid moves to the next stage, its pressure energy increases. The process continues until the fluid leaves the last stage at more pressure energy than it did at the first stage. The fluid exits the pump via the discharger port and moves to the required destination through the pipe network.

Figure: Working of a stainless steel vertical multistage pump

Types of stainless steel vertical multistage pump

Submersible stainless steel vertical multistage pump

This pump uses a hermetic design enough to operate while submerged in the fluid. The airtight design ensures no liquid can get into the pump to damage electrical and electronic components like sensors, thus increasing service life. Stainless steel vertical multistage pump manufacturers design this pump with a control switch to turn the fluid flow on and off. This pump uses a sensor to notify the pump operator when it has a technical problem. Submersible pump applications include clean liquids free from solids particles, effluent free, and slurries and sludge.

For the pump to operate in slurries, the manufacturer adds a grinding mechanism that helps cut large solids into smaller pieces that are easy to transport. The shredding mechanism also helps to prevent blockage of the pump due to large solids. This pump is advantageous because it is easy to operate, self-priming, and can work on clean fluids and slurries. It is mainly used in municipal and private sewage treatment applications.

Figure: Submersible stainless steel vertical multistage pump.

In-line stainless steel vertical multistage pump

This pump is also known as a straight-line pump. This pump is designed with the discharge and suction ports in a straight line with the pipeline. This pump design is suitable for limited space as it occupies less installation area than other pumps. The fluid flow in this pump does not change which also improves efficiency.

Magnetic stainless steel vertical multistage pump

This pump operates using magnetic technology instead of connecting the pump shaft directly to the electric motor shaft. Magnetic technology uses two magnets. One magnet is mounted outside, while the second is secured inside the pump. The outer magnet is meant to get rotary power from the motor shaft and transmit it to the inner magnet through a magnetic field pattern. As such, the rotation of the outer magnet forces the internal magnet to rotate. The inner magnet is connected to the pump shaft, and thus it enhances power transmission to the pump impellers at each stage.

Stainless steel vertical multistage pump manufacturers use magnetic coupling in pumps that are needed for transporting corrosive and hazardous fluids. Such fluids can be dangerous to the pump operators and the environment in case of leakage. These pumps do not use mechanical seals that wear out frequently; thus, they are free from fluid leakage. Also, this type of pump has a long service life of around ten years without replacing the magnets.

Factors to consider when selecting a stainless steel vertical multistage pump

Type of media

Various types of pumps are designed to operate for a specific type of fluid. For example, some of these pumps are meant for clean liquids free from solids. Fluid flow may get blocked if such a pump is used in fluid-containing slurries.

Flow rate

Stainless steel vertical multistage pump manufacturers design each pump with a specific flow rate range. Using the pump for a higher flow rate than recommended may reduce performance and shorten service life.

Pressure

Stainless steel vertical multistage pumps are of various stages, and thus they produce different pressure energies. Each pump can transport fluid based on pressure for a particular head or distance. As such, the pump should be used to transport fluid to the head specified by the manufacturer.

Power supply

An electric motor is used to power the pump. The manufacturer specifies the motor for use on each of the pump models. Using the pump with a low-rated motor will reduce pump performance. A higher-rated motor may damage the pump.

Applications of stainless steel vertical multistage pumps

- These pumps are used in fire hydrants for firefighting applications.

- They are used in used to supply water used in heating, ventilation, and air conditioning systems.

- They are used in irrigation systems to supply farmland water.

- Stainless steel vertical multistage pumps are used in sewage treatment and transportation.

- They are used in the food and beverage industries.

- They are used in pharmaceutical industries.

- They are used in the municipal and private water supply.

- They are used in crude oil refinery.

Advantages of stainless steel vertical multistage pumps

- These pumps are versatile as they are suitable for use in various industrial applications.

- They are powerful enough to withstand high pressure and high temperature.

- Stainless steel vertical multistage pumps occupy less floor space than their horizontal counterparts.

- These pumps are resistant to corrosion and abrasive wear.

- The submersible type of this pump can operate while submerged in the fluid being pumped.

- These pumps produce high-pressure energy compared to the single-stage pump types.

- Stainless steel vertical multistage pumps are cost-effective since they operate at a lesser price compared to other pumps. This allows for maximum industrial results.

- They have excellent efficiency due to small impeller diameters, which helps maximize the electric motor performance.

- They are easy to install and maintain. These pumps are fitted with sacrificial rings that are replaced periodically, which helps to protect the impellers and casing from premature wear.

- They can be used for clean liquids and liquids with slurries.

Disadvantages of stainless steel vertical multistage pumps

- These pumps need a large amount of headroom for maintenance and installation.

- It is challenging to balance hydraulic thrust on these pumps due to the overhang design, mainly where the pump is meant for use in high-pressure, high-suction applications.

- Stainless steel vertical multistage pumps are more expensive relative to single-stage pumps.

- They are hard to clean and repair due to the several impeller stages used.

Troubleshooting stainless steel vertical multistage pumps

Reduced pump performance

- Too high suction lift. Lower the pump if possible.

- Foot valve/suction hose obstruction. Check the foot valve or suction hose and remove blocking materials.

- Excess discharge head. Reduce the discharge head or use a larger pipe.

- Low speed. Increase motor speed within limits given by the stainless steel vertical multistage pump manufacturer.

- Air leakage through the suction line. Repair the suction line.

- Worn out seals. Replace seals.

The pump does not rotate

- Obstruction in the pump. Check the pump for blockage and remove blocking materials.

- Locked rotating parts. Disassemble the pump and apply rust preventative.

- Damage on drive coupling. Replace drive coupling.

- No power supply on the motor. Check if the motor is powered accordingly; consult an electrician or power company.

Pump is overheating

- Make the vent plugs lose to purge air.

- Clogged foot valve. Clean off obstructing materials.

- Too high discharge head. Reduce discharge head if possible.

Premature failure on bearings

- Shaft misalignment. Align shafts properly.

- Inadequate lubrication. Lubricate the bearings as recommended by the stainless steel vertical multistage pump manufacturer.

- Pipe not adequately supported. Use suitable braces and supports on the pipe.

- Contaminants are entering the bearings. Replace seals.

Premature coupling failure

- Align the rotating shafts properly.

- Improperly supported pipe. Use suitable braces and supports on the pipe.

Excess vibration

- Worn out bearings. Replace the bearings.

- Misalignment between the motor and the pump. Align them properly.

Summary

A stainless steel vertical multistage pump is a pump that is installed in a vertical orientation. This pump uses more than one impeller to generate fluid pressure. The working principle of this pump is based on the centrifugal force created by the rotation of the impellers at high speed. This rotation creates a vacuum in the pump, forcing the fluid into the impeller. Due to the impeller rotation, the fluid’s kinetic energy increases. The fluid proceeds to the next impeller while the kinetic energy is reduced and the pressure energy increased. The pressure energy rises for every impeller stage until the fluid finally leaves the pump through the discharge port.

Stainless steel vertical multistage pump manufacturers produce various types of these pumps, including magnetic drive pumps, submersible pumps, and in-line pumps. The advantages of these pumps are high versatility, less floor space, resistance to corrosion and abrasion, high-pressure energy, cost-effectiveness, and easy installation and maintenance. Applications of this pump include water supply, HVAC system, firefighting, foods and beverages, sewage treatment, and pharmaceuticals, among others.