What is an inline sewage pump?

An inline sewage pump is a type of centrifugal pump used for draining solid particles and long fibers. Inline sewage pump manufacturers also refer to it as a straight-line pump because its suction and discharge ports are oriented straight to the piping system. In other words, the centerline of the pump’s inlet and outlet is on the same level. It uses a unique impeller structure and mechanical seals that help to effectively contain fibers and solids as they are being transferred. The inline sewage pump features a vertical installation, single- stage and single-suction design. It also combines the characteristic of the basic water pump. The working operation of an inline sewage pump is based on the principle of gravity-fed sewage directly from the entry point. It has a relatively small size; hence it takes up less floor space compared to other types of sewage pumps. The pump inlet and outlet flanges are cast in a single body thereby making the pump easy to install and disassemble.

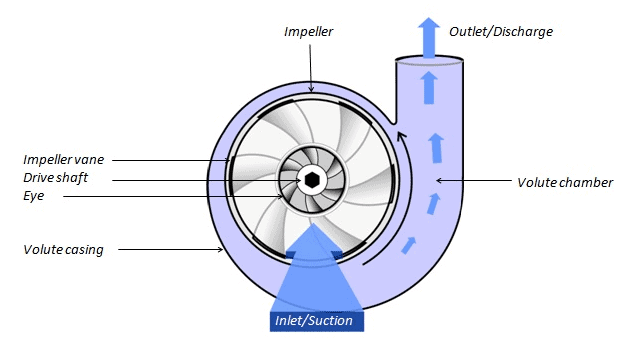

Figure: Configuration of an inline sewage pump

An inline sewage pump offers attractive performance metrics with a capacity of 3000 cubic meters per hour, a wide operating range of operating speeds (from 740 to 2900 RPM), and a maximum pressure head of 6 bars. It can handle medium temperatures of up 60 degrees centigrade. The inline sewage pump can perfectly cater to different applications, including industrial wastewater treatment, oily water, urban environment, construction, firefighting, pharmacy, dye, power plants, chemical industry, plating, paper making, washing of industrial mines, cooling of equipment, and many more. Inline sewage pumps are widely preferred because of their robust design, which is floor space-saving and easy to transport and mount. Inline sewage pumps can also handle fluids at high temperatures and pressure because the inline sewage pump manufacturers equip them with the ability to resist thermal expansion. An inline sewage pump requires less suction pressure because it is installed anywhere along the pipeline like a valve. The low suction pressure requirement allows the pumping medium to flow through the pump with ease.

How does an inline sewage pump work?

The motor impeller is rotated through a directly coupled AC electric induction motor. The rotation of the impeller creates a vacuum inside the pump casing. As result, the atmospheric pressure outside the pump forces the liquid into the pump casing through the pump inlet. When the liquid strikes the blades of the impeller, it is rotated radially and axially outwards, due to the centrifugal force acting on the blades, until it passes through all of the impeller components. The impeller blades impart kinetic energy to the liquid and direct it toward the diffuser chamber at a very high speed. In the diffusing chamber, the speed of the water is gradually decreased leading to the conversion of the high-velocity energy into a high-pressure head. The diffuser then guides the water to the pump outlet and into the delivery pipe to be transferred to the required location.

Figure: Working of an inline sewage pump