Introduction

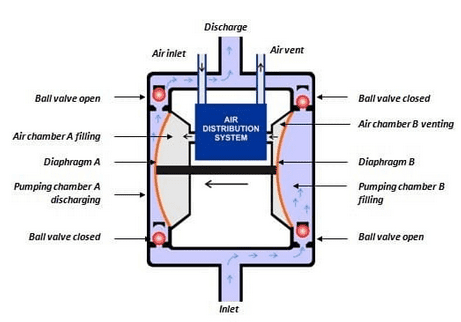

Air-operated double diaphragm pump is a very common type of diaphragm pump. As its name suggest, the pump operation is carried out using compressed air, rather than electricity. The air operated double diaphragm pump is made up of the two liquid chambers and two membranes/diaphragms. Each of the chambers has a discharged and suction check valve. Basically, the pump uses the two diaphragms to pump liquids in and out of the pump’s body. The flow of air flow of air between the chambers is controlled through and inbuilt air spool control device. The flow of air from one membrane to another causes one chamber to expel fluid through the discharge and also facilitates the suction of fluid in the other chamber. Due to their unique operation characteristics, air operated double diaphragm pumps are suitable for applications where the use of electricity would be disastrous e.g., pumping of flammable liquids.

Fig: The components of an air operated double diaphragm pump (image credits: michael-smith-engineers.co.uk)

The air operated double diaphragm pump uses specially designed check valves to control the flow of fluid in and out of the central chamber during pump operation. The function of the check valve is to ensure the fluid flows in one direction only.

Application of air operated double diagram pump

Air operated double diaphragm pump pumps are extensively used in various industries for wide range of purposes as highlighted below

Biopharmaceutical manufacturing, food and beverage industries

- Air operated double diaphragm pump are used in injection of additive

- chemical dosing

- To transfer corrosive, abrasive and toxic chemicals

- Coating

- unloading raw material

- Aseptic transfer of proteins and cells

- Air operated double diaphragm pump shear-sensitive processes

- Filter presses

- To produce the required flow and pressure for spraying and cleaning tasks.

- loading and unloading tankers, totes and barrels

Waste water treatment plants

- Transferring solid lade media

- Air operated double diaphragm pumps are used as utility pumps

Oils and gas

- oil and glycol transfer

- settling pond transfer

- filter presses

Mining

- Dewatering sites and quarries

- pumping abrasive slurries and sludge mixtures

- Transferring solvents for separating minerals from ore

- moving fuels for vehicles and equipment

Electroplating and anodizing

- Air operated double diaphragm pump replenishing chemicals in plating and metal finishing tanks

- Offloading corrosive as well as solid laden waste

- Agitating cleaning solutions

- Circulating liquid to avoid sedimentation

- Filtration (when critical purification is required for high quality parts)

Advantages of air operated double diagram pump

- Can run dry-unlike conventional pump an air operated pump can run dry for a long time without damage or any operational issues. This is because the pumps have no internal seals or moving parts that require lubrication. Conventional pumps such as the lobe pump, magnetic drive pumps, centrifugal pump would have to stay primed during operation to prevent damage to some of their components, which can lead to expensive repairs.

- Safety- The pump can be used for flammable liquid because they are air powered and cannot produce spark. Also suitable for volatile chemicals

- The pump requires minimal repairs- The pumping fluid is separated from sensitive pump components; hence increased time between repairs

- Application versatility- the pump and the diaphragms are made from a variety of material enabling the pump to have a wide range of applications. They area also capable of handling variety of feeds ranging from low viscosity to high viscosity fluids.

- Can be used for sanitary and food grading processes

- Simplicity- the pump design does not involve complex wiring or electrical controls. This makes the pump easy to install and operate

- Does not require electricity

- Suitable for corrosive, abrasive and powdered materials

- relative low cost and reliable

Disadvantages of air operated double diagram pump

- The efficiency of AODD depend on the quality of compressed air.

The pressure of compressed air must be higher than the pressure of the fluid to be pumped.

- The pump is prone to icing.

This may occur due to constant venting which can cause ice to build up around the air vent or within the air distribution system. This challenge can be solved by installing a heater or maintaining the pressure of compressed air at the level recommended in the pump manufacture’s guide

- AODD pump produces a pulsating discharge

This is caused by the cycling action of the diaphragm which cause the fluid to accelerate during compression cycle and to slow down during the suction cycle, creating pulses in the discharge. To solve this problem, a dampener must be installed on the top of the pump to decrease the pulses.

- The pump can be noisy

Noise in AODD pump is caused by the constant venting of the air valves and vibrations resulting from the cyclic action of the diaphragm and. The level of noised can be reduced by installing the air vent line with a muffler.