In daily life, we often encounter situations where water pressure is insufficient or the water flow is low. In such cases, booster pumps can perfectly solve the problem. Booster pumps have a wide range of applications in both daily life and industry. This article will provide you with a detailed introduction to the structure, working principles, various types, advantages and disadvantages, applications, maintenance, and how to select booster pumps. It will give you a comprehensive understanding of booster pumps.

What is Booster Pump

Booster pumps, as the name suggests, are devices that convert low-pressure fluid into high-pressure fluid. They not only transport media but also, based on the pressure requirements of the media, connect low-pressure fluid at the input end. Through the operation of the booster pump, they output the desired pressure and flow rate. The media can be either liquid or gas.

Booster Pump Construction

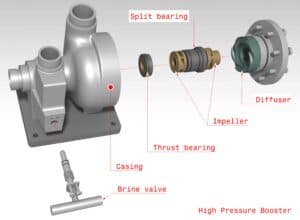

Although there are many types of booster pumps, their structures are generally similar, with the main components including:

- Pump Body: The pump body is the primary component of the booster pump, typically made of materials such as cast iron, stainless steel, or special materials. These materials possess high mechanical strength to withstand the pressure of the media. The pump body is usually designed in a circular or conical shape to reduce flow resistance and improve efficiency. It has inlet and outlet ports, with the media being drawn in from the inlet and discharged from the outlet after being pressurized.

- Impeller: The impeller is a crucial component of the booster pump and is closely related to its efficiency. It is installed within the pump body with a certain gap maintained between the impeller and the inner wall of the pump body, allowing the impeller to rotate smoothly. Additionally, the impeller needs to have good sealing properties to prevent media leakage.

- Drive Device: Common drive devices for booster pumps include electric motors and internal combustion engines, which serve as the power source for the pump. The drive device is connected to the impeller via the pump shaft, thereby driving the rotation of the impeller to achieve the boosting function.

- Flow Meter and Valves: Flow meters are used to detect the pressure at the outlet of the booster pump, and valves are then adjusted as needed to control the direction and flow rate of the fluid.

- Filter: Media may contain impurities to varying degrees. If these impurities enter the pump body, they can potentially damage critical components. Therefore, filters are necessary to remove impurities from the media.

- Other Accessories: Other accessories such as seals, connectors, etc., are included to ensure the smooth operation of the booster pump.

How does Booster Pump Work

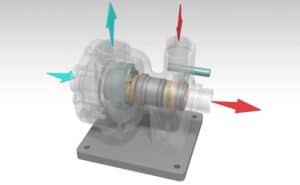

The working principles of booster pumps can be divided into two categories: dynamic boosting and displacement boosting.

Dynamic Boosting: The principle of dynamic boosting pumps involves drawing in low-pressure liquid or gas through the pump’s inlet into the pump chamber. Then, mechanical components such as rotors or pistons within the pump chamber compress the fluid, ultimately expelling high-pressure liquid or gas from the pump outlet.

- Displacement Boosting: Displacement boosting pumps operate by altering the volume within the pump chamber to compress liquid or gas. These pumps typically consist of one or more mechanical components such as pistons, plungers, or screws. As these mechanical components move forward within the pump chamber, the fluid is compressed, resulting in an increase in pressure, and eventually expelled from the pump outlet.

Regardless of whether it’s dynamic boosting or displacement boosting, the working process can be broken down into four steps:

- Media Intake: Drawing in low-pressure liquid or gas into the pump body.

- Pressure Increase: Utilizing rotor rotation or piston displacement to impart energy to the media, increasing pressure and flow velocity.

- Media Discharge: After acquiring energy, the media is expelled from the outlet through a flow path.

- Control Mechanism: When there is a requirement for precise output pressure or flow rate, a control mechanism is installed to monitor and adjust the pressure of the discharged media.

Booster Pump Types

- Centrifugal Booster Pump: Centrifugal booster pumps utilize centrifugal force to draw in liquid or gas, increasing its pressure and velocity through the rotation of impellers or blades, and then expelling it. They are suitable for water supply systems, air conditioning systems, and industrial fluid transportation.

- Plunger Booster Pump: Plunger booster pumps operate by changing the volume of the working chamber using plungers to achieve the intake and discharge of liquid. They are suitable for transporting various media, including highly concentrated particle sewage, and are commonly used in petroleum and natural gas extraction, irrigation, agricultural spraying, and high-rise building water supply. They are characterized by high output pressure and strong medium conveying capacity but have complex structures and maintenance difficulties.

- Screw Booster Pump: Screw pumps utilize two or more intermeshing screws or helical blades to form sealed chambers in the pump cavity. Through rotational movement, they propel and pressurize the medium. They are suitable for industries such as chemical, petroleum, and food.

Booster Pump Application

- Industrial Sector: Booster pumps have wide applications in the industrial sector, such as the petroleum and chemical industries, where they are used to provide the necessary pressure and flow rates.

- Agricultural Sector: Booster pumps are commonly used in agricultural production for tasks like irrigation and spraying.

- Construction Sector: High-pressure water is required in construction for water supply and drainage systems, as well as firefighting operations, especially for high-rise buildings.

- Medical Sector: Many medical devices in hospitals require the use of booster pumps for the transmission of gases or liquids, such as oxygen supply systems.

- Residential Sector: Booster pumps are essential for various household applications in our daily lives, including showers, tap water systems, and water heaters.

Advantage of Booster Pump

- Simple Structure: Booster pumps have a compact structure with fewer required components and seals, resulting in lower maintenance costs.

- Increased Efficiency: Booster pumps convert low-pressure fluid into high-pressure fluid, thereby enhancing operational efficiency.

- Wide Applications: The control systems within booster pumps allow for precise adjustment of output medium pressure according to specific requirements, making them suitable for various usage scenarios.

- Long Lifespan: Booster pumps are constructed using high-strength materials resistant to high pressure, ensuring a longer lifespan.

- Versatility: Booster pumps can be utilized with various gases, liquids, and hazardous media, making them highly versatile in different environments.

Disadvantage of Booster Pump

- Noise Pollution: Booster pumps generate noise during operation, which can contribute to environmental pollution. However, this can be mitigated by installing noise reduction devices.

- Clogging of Passages: Prolonged usage of booster pumps can lead to the obstruction of passages, resulting in decreased operational efficiency.

- Damage to Internal Components: Extended usage may cause wear and tear on internal components or seals, leading to increased maintenance costs.

- Unstable Output Pressure: Malfunction or damage to the control device can result in unstable output pressure, affecting the performance of the booster pump system.

Booster Pump Installation Instructions

- Preparation: Ensure that the model and specifications of the booster pump match your requirements. Check the pump body, motor, and components for any damage or looseness. Clean the installation site to ensure there are no debris or dust particles.

- Select Installation Location: Choose a dry, well-ventilated area capable of supporting the pump body and motor stably. If possible, opt for indoor installation to facilitate maintenance and reduce noise.

- Secure Pump Body and Motor: Place the pump body on the designated bracket and secure it using bolts and nuts, ensuring a tight and reliable connection.

- Connect Inlet and Outlet Pipes: Based on the direction of the pump’s inlet and outlet, connect the inlet and outlet pipes. Use gaskets and sealant to ensure a tight connection, preventing leaks and seepage.

- Bleed Air: After installation, open the pump’s air release valve to bleed out any air until the pump body is filled with water, then close the air release valve.

- Electrical Wiring: Ensure that the power supply meets the input voltage and frequency requirements of the pump. Use a three-core safety socket with grounding wire. Connect the motor’s grounding wire to the grounding device. Then, refer to the electrical wiring diagram of the pump to connect the power supply wires according to their colors.

- Start-Up and Commissioning: After filling the pump body with water, close the inlet valve and turn on the power switch to start the pump. Observe the pump’s operation and address any abnormalities promptly. Adjust the operating status by monitoring the inlet and outlet water pressure and flow rate.

Booster Pump Testing and Commissioning

- Connect the inlet port of the booster pump to the gas source. Typically, the inlet port is marked with a symbol, so make sure not to connect it incorrectly.

- Connect the outlet port of the booster pump to the system where oil is needed. Similarly, the outlet port is also marked.

- Turn on the gas source and oil supply to allow gas and oil to flow into the booster pump.

- Open the pressure adjustment knob on the booster pump and gradually increase the pressure until the desired standard pressure is reached. Maintain pressure for a period of time and observe the pressure gauge readings and whether there is any oil leakage from the pump body.

- If significant pressure adjustment testing is required, gradually release pressure and then readjust and maintain pressure as needed.

- If oil leakage is detected, locate the leakage point on the pump and observe the leakage status.

- If there is oil leakage, close the inlet port of the pump, disassemble the pump body to find the leakage point, and carry out the necessary repairs.

Here are some precautions to consider:

- Before testing, ensure that the gas source and oil supply are stable and clean.

- During testing, strictly control the pressure of the booster pump to avoid damaging the pump body and surrounding systems.

- If oil leakage is detected from the booster pump during testing, stop the test immediately and conduct inspection and repairs.

- Personnel involved in testing should wear protective gear, such as pressure suits, to avoid injury from any spilled liquids.

Booster Pump Maintenance Guide

- Check Power Supply and Switch: Start by inspecting the power supply and switch of the booster pump. If the switch is set to manual mode, you can try short-circuiting the power supply to see if the booster pump starts working. If it operates normally after short-circuiting, it indicates a problem with the flow switch, which may need cleaning or replacement.

- Disassembly and Inspection: If the problem persists, you’ll need to disassemble the outer casing, motor, and pump head system of the booster pump to inspect the internal components of the pump head system, including the condition of bearings, seals, and valve wear.

- Replacement of Components: Based on the inspection results, replace any components that need replacement.

- Cleaning and Assembly: Clean the pump head system and motor internals, then reassemble them, making necessary adjustments to ensure the booster pump operates properly.

- Check Water Pipes and Check Valves: If the booster pump stops running shortly after starting, it may be due to water leakage in the pipes, which needs to be inspected and addressed. If there is air in the pipes, it may cause backflow issues, which can be resolved by installing check valves.

During the repair process, always ensure that the power supply is disconnected to prevent electrical accidents. If you are unsure how to proceed, it’s advisable to seek assistance from a professional repair technician.

Booster Pump Selection Guide

When selecting a booster pump, several factors need to be considered to ensure that the pump meets specific requirements. Here are several key points to consider during the selection process:

- Clearly understand the on-site water supply situation: For industrial water supply, special consideration may not be necessary; however, for domestic water supply, it is important to determine whether water storage tanks are needed, as well as the size of water pipes, water pressure values, and water supply stability.

- Determine the required maximum flow rate and maximum head or pressure: Flow rate refers to the pump’s drainage capacity, usually measured in cubic meters per hour or liters per second; head refers to the height to which the pump can lift water, typically measured in meters.

- Determine the type of pump: Choose a suitable pump type based on the application scenario. For example, horizontal single-stage pumps are suitable for scenarios with low flow rates and low heads, while multi-stage pumps are suitable for scenarios requiring increased head.

- Determine the material: Select appropriate materials based on the operating environment, such as cast iron, stainless steel, or composite materials.

- Determine control factors: If the booster pump is used in an automatic control system, consider the type of control, as this directly affects the pump’s operating efficiency and user experience.

- Consider installation location and design requirements: The choice of installation location has a significant impact on the pump’s operating performance. Choose a location that is low-noise, dry, well-ventilated, and easy to access for maintenance.

- Consider the pump’s input voltage and frequency: Ensure that the pump’s input voltage and frequency match the power supply.

- Consider the pump’s noise level: Choose an appropriate noise level based on the operating environment.

- Consider the pump’s weight and size: Ensure that the pump’s weight and size are suitable for the installation location.

In summary, when selecting a booster pump, it is important to consider multiple factors comprehensively to ensure that the pump operates efficiently, reliably, and effectively over the long term.

Conclusion

This article provides a comprehensive overview of booster pumps, covering their structure, working principles, various types, advantages and disadvantages, applications, maintenance, and selection criteria. Through detailed explanations and practical guidance, it aims to enhance understanding of the operation mechanisms of booster pumps and how to choose the appropriate pump type to meet specific needs. Additionally, the article includes a FAQ section addressing common questions that you may encounter.

FAQ:

What is Booster Pump Output

The output of a booster pump typically refers to the water flow pressure or flow rate it can provide. The flow rate determines how much fluid the pump can handle per unit of time, which is particularly important for applications requiring continuous and large-scale fluid delivery.

Booster Pump Life Expactancy

The lifespan of a booster pump is a complex issue influenced by various factors, including the pump’s quality, operating conditions, maintenance, and environment. Generally, high-quality booster pumps can have a longer lifespan when used and maintained correctly.

Will Booster Pump Increase GPM?

Yes

Does Booster Pump Need Pressure Tank?

A booster pump may not necessarily require a pressure tank. This mainly depends on the specific application and requirements.

In some cases, a booster pump can be directly connected to the water supply system to increase water pressure and meet usage needs without the need for an additional pressure tank. However, in certain specific applications where water storage and pressure regulation are necessary, a pressure tank might be beneficial.

How Long Can A Booster Pump Run Continuously?

The duration for which a booster pump can continuously operate primarily depends on several factors, including the quality of the pump, its design, working environment, maintenance condition, and operating load. Under ideal working conditions, some high-quality booster pumps are designed for long-term continuous operation, capable of running for several hours or even days without experiencing any failures.

What Is The Inlet Pressure of Booster Pump?

The inlet pressure of a booster pump refers to the pressure of the fluid when it is being drawn into the booster pump.

Why is My Booster Pump So Loud?

The reasons for noise from a booster pump can vary, but some common causes include internal pump issues, installation problems, issues with the suction inlet, power supply problems, flow rate and flow volume issues, and environmental factors