Types of inline sewage pump

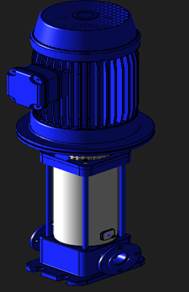

Vertical inline sewage pump

A vertical inline sewage pump consists of a vertically oriented shaft that is close coupled to the pump head. It is the most common design of an inline sewage pump. Sometimes the pump can be long-coupled via the use of a spacer bracket acting as a support for the motor. The long-coupled design allows easier pump maintenance because the motor does not have to be removed during repair.

Figure: Showing a vertical inline sewage pump.

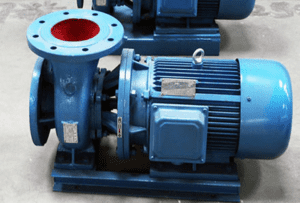

Horizontal inline sewage pump

A horizontal centrifugal pump is characterized by a horizontally oriented shaft and impeller, typically between pump bearings. The motor is located on the same horizontal plane and adjacent to the pump

Figure: Showing a horizontal inline sewage pump

Applications of an inline sewage pump

Inline sewage pumps find a wide range of applications in different industries, such as urban wastewater treatment plants, construction, firefighting, pharmacy, industrial mines, paper making, etc. Typical uses include:

- An inline sewage pump is used for transferring sewage in treatment plants

- It is also used for pumping industrial wastewater.

- Inline sewage pumps are also applied in the washing of industrial mines

- It is also used for moving oily water.

- It is also used in private homes and buildings that are not connected to municipal sewers due to the nature of the terrain.

- It is used in chemical industries to transport viscous fluids.

- It is also used in industrial recirculation.

- It can also be used in fire control.

- It is used for pumping any liquid containing suspended particles and fibers.

Advantages of inline sewage pump

- An inline sewage pump has high reliability and efficiency

- Inline sewage pumps are suitable for high pressure and temperature because they can resist thermal expansion.

- Inline sewage pumps require small space for installation. The motor and service clearance is located above the pump casing, requiring less floor space for pump installation.

- Inline sewage pumps do not require regular maintenance because they have few parts that experience wear.

- Inline sewage pumps are easier to install and operate because they have a simplified construction. The close-coupled design does not require shaft alignment or additional bearing assembly.

- Inline sewage pumps also have a low Net Positive Suction Head Requirement (NPSHR) and thus can easily move fluid through the pump.

- An inline sewage pump produces less noise and vibration.

The vertical shaft orientation is naturally balanced and gravitation forces do not oppose the shafts rotation direction.

Disadvantages of inline sewage pump

- An inline sewage pump can be difficult to maintain because the motor and impeller must be disassembled from the volute to service the mechanical seals. This is particularly a major challenge for the pump with large motors, above 25 hp.

- The inline sewage pump requires vertical clearance for installation and maintenance.

- They have the risk of running backward especially when the pump is stopped without first closing the discharge line.

- Air leakage can reduce the inline sewage pump capacity.

- The weight of the pump falls below the volute, leading to a large stress concentration.