What is slurry?

A slurry is a mixture of water and other solid components. Slurry is mostly produced in industries such as agriculture, mining, and construction. The slurry is sloppy and thin and flows easier compared to sludge.

What is a slurry pump?

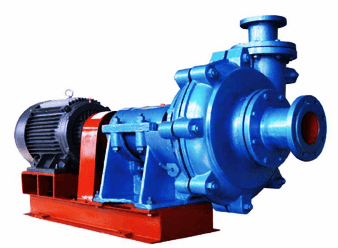

A slurry pump is a particular type of centrifugal pump used for transporting slurries. An electric motor or a diesel engine powers the pump. The power from the prime mover is transmitted to the pump via a shaft. Energy from the shaft is transmitted to the pumped content via a component known as an impeller. The impeller is a circular disc with curved vanes on its face. The impeller creates a vacuum inside the pump when it is turned on. The vacuum helps to force the content into the pump. The impeller rotation adds flow velocity and pressure energy into the content to ensure it reaches the required destination.

Figure: Slurry pump.

How to select the best slurry pump

The best slurry pump is selected by considering several factors to ensure cost-effective pumping. These factors are:

Know the type of material to be pumped.

The material could be sand, mud, slurry, etc. Also, know the properties of the pumped media, such as density, viscosity, operating temperature, and PH level. This will help select a powerful pump to handle the fluid. It also helps to choose a pump that will not deteriorate due to operating temperature and PH level.

Flow rate

Flow rate measures the fluid/content pumped per unit of time. Flow rate units are liters/second, gallons per minute (GPM), or m3/hr. The slurry pump selected should be capable of providing the required flow rate, and this can be done by determining the flow rate before purchasing.

Pump construction material

The pump selected should be made of materials that are chemically compatible with the pumped fluid. If the construction materials and the pumped content are incompatible, the pump may crack or melt down and cause severe damage to the pump and the surrounding area and injury to the workers around it.

Inlet and discharge pipe

Pipe diameter, length, and material are critical factors that must be considered to select the best slurry pump. Pipe length is crucial because the more the pipe, the more content build-up will occur, and thus, there is a need for substantial motor power to ensure the fluid is taken to its destination. Pipe diameter is vital as it will help reduce discharge head pressure and maintain enough fluid velocity to prevent clogging on the discharge pipe.

Power

The pump power is given in horsepower (HP). The amount of energy depends on other factors like flow rate, viscosity, and specific gravity of the pumped media. Heavy and thick fluids need more transport power than thin and light fluids. Also, the power should be high enough to overcome forces in the discharge pipe downstream of the slurry pump.

Operating cost

It is essential to consider the economic impact and cost of the pump. The best pump selected should be based on how much money it needs to operate for a particular duration. The pump should be cost-effective to ensure energy bill is relatively low. Also, the pump should fit the applications to reduce the chances of unnecessary shutdown due to frequent repairs and, thus, unnecessary costs.

Pump elevation

The place where the pump is installed should be fine with its operation and maintenance. Where the pump is installed above the fluid to be pumped, it should be located such that it is capable of drawing fluid. If the pump is far from the source of the liquid, it may not be able to suck in the fluid, and thus no pumping will occur.

Pump orientation

Slurry pumps are designed for installation in either vertical or horizontal position. The vertical type is suitable for use with small floor space but enough vertical space. On the other hand, the horizontal type is best for use where the vertical space is limited, but there is ample floor space.

Features of a slurry pump

- Large inlet and discharge ports. These allow the slurry to enter and exit the pump without clogging. Also, the large sizes allow significant flow rates without clogging.

- Resistance to abrasive wear. The pump is meant to work in abrasive materials and thus coated with abrasive-resistant materials.

- Resistant to corrosion. Slurry pump manufacturers design the pump for use in different applications, some of which handle corrosive materials and are thus made of corrosion-resistant materials.

- High strength. This pump is made of high-strength metallic materials like steel, which makes it capable of handling high flow rates and high pressure for decades.

- Robust impeller. The impeller used in slurry pumps is heavy and thick to enhance its strength against abrasive solids.