What is a diaphragm pump?

A diaphragm pump is a type of positive displacement pump. It is also called an operated double diaphragm (AODD) pump. As the name suggests, this pump operates by use of compressed air. It is designed with a pneumatic valve meant to direct air back and forth on the two sides of the pump.

Two flexible diaphragms move back and forth. The movement of these diaphragms causes a vacuum due to pressure difference. The created vacuum helps introduce and discharge the liquid into and out of the pump. The figure below shows the components and working of a diaphragm pump.

Figure: Components of a diaphragm pump.

Figure: Working of a diaphragm pump.

What is a centrifugal pump?

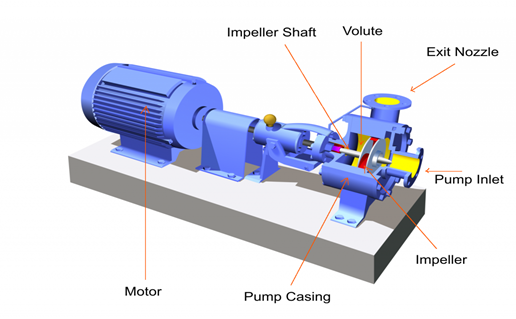

As the name suggests, a centrifugal pump is a type of pump that uses centrifugal force to transfer fluid from one point to another. The centrifugal force is created using impellers that spin at high speed between 1000 to 3000 rpm. An electric motor or diesel engine usually powers the pump. The motor/engine (prime mover) provides mechanical energy to the pump. The rotational (mechanical) energy is converted by the pump components called impeller/rotors and casing into pressure energy. The pressure energy helps to move the liquid from its source to the required destination. The figure below shows a centrifugal pump, its components, and the working principle.

Figure: A centrifugal pump.

Figure: Components of a centrifugal pump.

Figure: Working of a centrifugal pump.

Differences between diaphragm and centrifugal pump

- Performance. Diaphragm pumps are designed to deliver constant flow rates irrespective of the distance or varying pressure. The flow rate in a centrifugal pump varies depending on pressure level. Also, a centrifugal pump must be primed before regular pumping. If not properly primed, it does not deliver fluid as required. On the other hand, a diaphragm pump does not need to be primed as it has self-priming features.

- Based on the working principle. Diaphragm pumps transfer fluid using a flexible diaphragm that moves forward and backward to create pressure difference. The pressure difference drives the liquid through the pump to the indented destination. The diaphragm moves in one direction, creating a vacuum that moves liquid from its source into the pump’s chamber. When the diaphragm moves in the other direction, it compresses the fluid, forcing it from the pump to the required destination. On the other hand, a centrifugal pump uses impeller/rotors that rotate at high speed to create a vacuum inside the pump. Due to the vacuum, the fluid moves from its storage tank into the pump. When it enters the pump, it finds the rotors moving at high speed. As such, the rotors add kinetic and pressure energy to the fluid, making it possible to move to the required destination.

- Based on the fluid being pumped. Diaphragm pumps are designed to operate on highly viscous fluids without such fluids affecting flow rates. On the other hand, centrifugal pumps are meant to work on relatively low viscous fluids because highly viscous liquids cause frictional losses (pressure losses).

- Required applications. Centrifugal pumps perform best when transferring low viscous fluids at high volumes, high flow rates, and low pressure. Diaphragm pumps do best on applications dealing with high-pressure and low-flow rates. For example, in food processing plants, a centrifugal pump is used to transfer water, while a diaphragm pump is used to move thicker compounds.

- Diaphragm pumps are more complex in design relative to the centrifugal pump. This makes their repair and maintenance more expensive, unlike centrifugal pumps.

- Centrifugal pumps have less power consumption, higher efficiency, and less noise relative to diaphragm pumps.

Similarities between the diaphragm and centrifugal pump

- Both of these pumps transfer fluids by creating a vacuum. A vacuum is a state of lower pressure than atmospheric pressure. Due to the pressure inside the pump being low, the atmospheric pressure tries to create some pressure balance by pushing fluid into the pump. This then initiates the fluid flow to the required destination.

- Centrifugal and diaphragm pumps transfer fluids from the inlet to the outlet point. They have suction and discharge points with suction and discharge valves, respectively.

- They are available in variety of sizes for different flow rates and head.