What is a peristaltic pump?

A peristaltic pump is a positive displacement pump with a flexible tube that transfers fluid through various rollers or shoes that compress and release the tube. The compression and release mechanism produces a squeezing or peristaltic action that moves the liquid at a consistent rate. Typical to other pumps, a peristaltic pump contains a pump head, motor, and control system. The pump head has shoes or rollers and a flexible tube. The electric motor provides the power to drive the shoes/rollers to create the compression and release action. The peristaltic or squeezing action is produced when the shoes/rollers rotate. The control mechanism helps to regulate the direction and flow rate of the fluid by adjusting motor speed and direction.

Figure: Peristaltic pump.

How does a peristaltic pump work?

A peristaltic pump operates on the principle of positive displacement. When the pump is turned on, the liquid is introduced into the flexible tube by rollers. The rollers rotate and press the tube against the pump casing. When the roller rotates past specific points of the tube, the roller volume increases, allowing more fluid to get in for the next pass of the roller. Peristaltic pump manufacturers design these pumps with at least one roller to close the tube when transferring liquid, which helps to ensure no need for valves. When the rollers and track circle the whole tube, it generates a full closure of the tube, leading to a positive displacement effect. The positive displacement effect helps to prevent fluid from flowing backward. It also excludes the need for a check valve when the pump is not in operation.

Figure: Working of a peristaltic pump.

What is a centrifugal pump?

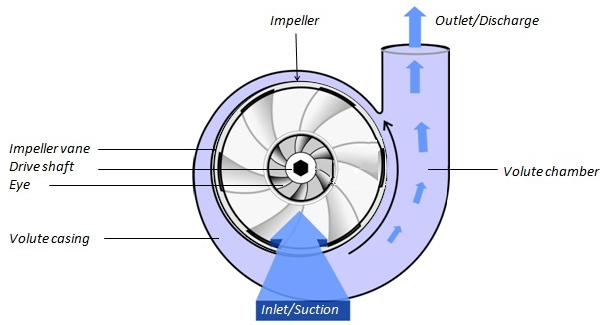

A centrifugal pump is a pump that pumps fluid by use of centrifugal force. An electric motor or diesel engine powers the pump. The design entails a shaft that transmits power from the prime mover (electric motor or diesel engine) to the pump. The pump has a metallic disc component known as an impeller. The impeller has curved vanes running from its center to the circumference. The work of the impeller is to create a vacuum (state of low pressure relative to the atmospheric pressure). There are two types of impellers: closed and open impellers. Centrifugal pump manufacturers design the closed impeller for clean fluids, while the open impeller is designed for use in fluids with suspended particles.

Figure: Centrifugal pump.

How does a centrifugal pump work?

When the pump is turned on, the motor provides mechanical energy to the shaft through rotation at high RPMs. As such, the pump shaft and impeller rotate at the same RPMs. Due to the impeller rotation, a vacuum is created inside the pump. The vacuum forces atmospheric pressure on the surface of the fluid to move fluid into the pump via the suction line. The fluid enters the pump and meets the impeller at its center. The impeller rotation imparts kinetic energy into the liquid, enhancing its flow velocity. The fluid moves out radially on the impeller to the pump casing. Inside the casing, the flow velocity reduces while pressure energy increases. The pressure energy helps to move the fluid to the required destination.

Figure: Working of a centrifugal pump.

Benefits of peristaltic pump over centrifugal pump

- These pumps are the best for handling corrosive and viscous fluids since it is only the flexible tube that comes in contact with the liquid being pumped.

- Peristaltic pumps are self-priming due to their design features. This relieves the pump operator of the need for priming the pump, which is common in centrifugal pumps.

- They are easy to repair and do maintenance. The commonly worn component is the hose, whose replacement is straightforward and quick.

- They are reversible. This means that the roller rotation can be reversed to serve in different scenarios, such as emptying and filling containers.

- Non-clog. The design of peristaltic pump accommodates solid particles to the size of the hose’s internal diameter without clogging. As such, these pumps are suitable for use in sludge, sewage, and other applications where solids are inevitable.

- They have low shear. As such, they can handle very sensitive fluids without damaging cell culture or changing consistency.

- They resist abrasive wear due to their hard-wearing hose, gentle action, and slow speed. Thus, it is suitable for use where fluid contains debris and sharp particles, like in mining.

- Do not have valves. Thus, there is no risk of solid build-up or clogging.

- Variable speed. The flow rate of these pumps is proportional to the speed while pressure remains constant.

- They do not need seals common in centrifugal pumps. As such, they have low maintenance requirements.