Screw Water Pump

What is a screw water pump?

A screw water pump, also known as water screw, is a rotary positive displacement pump comprising one or several screws designed to pump water. The screw rotates within a cylindrical cavity to increase the water pressure and move it from one location to another. It works on the positive displacement (PD) principle, where it repeatedly encloses a fixed volume of water and transfers it mechanically through the pump system. The liquid moves along the cavities due to positive displacement and gets discharged from the pump’s discharge port. The head developed is independent of the pump speed, while the capacity is proportional to the pump speed. The oldest version of the screw water pump is called the Archimedes screw pump. Screw water pump manufacturers design the pump to not only excellently transfer water but also move several other fluids such as viscous fluids, fuel, lubricating oil, injection fuel, and many more.

Screw water pump manufacturers tailor the pump for several industries, including wastewater, shipping, chemicals, paper, ceramics, oil and gas processing, etc. A screw water pump can efficiently transfer abrasive and non-abrasive liquids, with and without solid particles

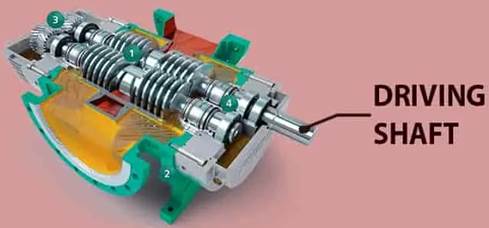

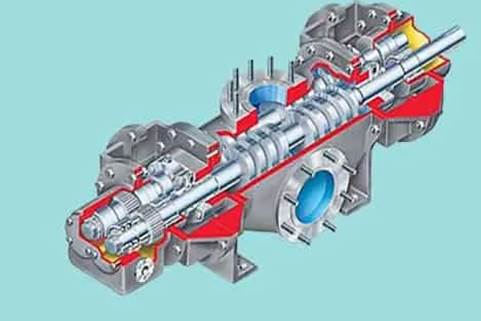

Figure: showing the configuration of a screw water pump

Components of a screw water pump

Electric motor

The motor is the component that provides power required to operate the pump. It operates by converting electrical energy to mechanical energy. The mechanical energy is transmitted to the pump via a shaft in terms of torque and angular speed.

Pump casing

The pump casing houses all the internal components of the screw water pump, such as a screw(s) and bearing. It is sealed to prevent the leakage of pumping fluid under pressure. The pump casing can be either radially split or axially split. In a radially split case, the two halves open perpendicularly to the screw axis, while in the axially split casing, they open parallel to the screw axis. The screw water pump uses an axially split case because it provides excellent hydraulic performance, is easy to maintain, and facilitates easy replacement of screw seals. Screw water pump manufacturers create pump casings from a wide range of materials, including grey cast iron, carbon steel, stainless steel, alloy steel, etc.

Driver screw (male rotor)

The driver screw is part of the pump’s rotor assembly. It rotates the driven screw through a timing gear, helping to move the fluid at a constant volumetric level at any location. Driver screws are often made of high-tensile steel, surface-treated steel, and Alloy steel.

Driven screw (female rotor)

The driven screw also constitutes the rotor assembly and turns about its axis due to the torque transmitted by the timing gear. The driven screw rotates opposite the driver screw while maintaining a uniform clearance area. Because the screws rotate in opposite directions and keep a fixed clearance area, they move the fluid along the rotating angle, providing a non-pulsating discharge.

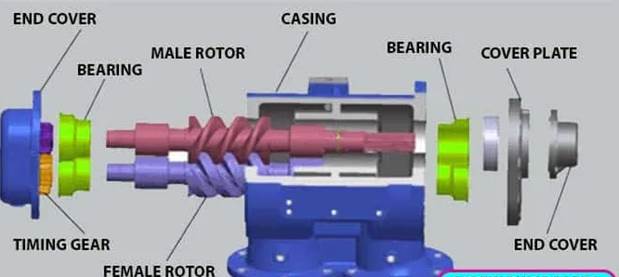

Driving shaft

The driving shaft is an integral part of the pump connecting the pump assembly with the electric motor through a set of flexible couplings. Screw water pump manufacturers make driving shafts from mild steel, stainless steel, or carbon steel to withstand heavy loads, high speeds, and vibration, which can cause a large amount of stress during operation.

Figure: showing the driving shaft of a screw water pump.

Bearings

The bearings support the screws and ensure they align perfectly operation. A screw water pump comprises two kinds of bearing: upper and lower bearings. The upper bearings usually carry heavy loads along with axial and radial forces during pumping. On the other hand, the lower bearings experience minor loads and are responsible for maintaining a perfect alignment of the pump’s components.

Timing gear

The timing gear primarily transmits rotary motion from the drive screw to the driven screw. Also, it ensures that the screws maintain the delicate clearance area between them without coming into direct contact during operation.

Suction and discharge pipes

The suction pipe allows the fluid into the pump while the discharge pipe directs the pumping fluid out of the pump and to the required destination. To prevent the pump from becoming dry, the screw water pump manufacturers design the suction and discharge ports to hold some fluid when the pump stops. This fluid acts as the starting liquid medium in subsequent pump operations. Suction and discharge pipes are attached to the pump casing via flanges or pipe unions.

Figure: showing various components of a screw water pump.

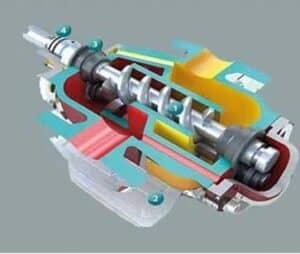

How does a screw water pump work?

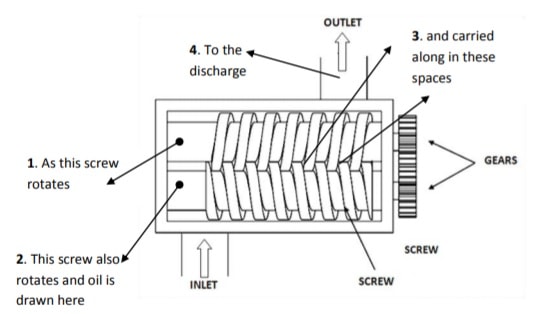

When the motor starts, the driving shaft transmits the rotary motion to the drive screw. The driver screw then rotates the driven screw through a timing gear. As both screws rotate in phase within the pump casing, their threads intermesh with a fine clearance area creating sealed cavities that progressively move from the suction to the discharge end. These cavities trap air and push it axially to the discharge port, creating a differential pressure that helps to draw pumping liquid into the pump. As the male and female rotors continue rotating, they axially accelerate the liquid, increasing its pressure and moving it toward the outlet port. The sealed cavities move at a constant volume and uniform speed between the casing and the screws, allowing an even flow over the length of the pumping elements. As a result of the gentle and continuous meshing of screw threads, a screw water pump provides silent operation with low shear and flow pulsations.

Figure: Working of a screw water pump

Types of screw water pumps

Screw water pumps are available in various types, distinguishable by the number of screws within the pump casing, but they generally operate following the positive displacement principle.

Single or one-screw water pump

A single-screw water pump consists of one screw with one helix and rotates in a double helix stator. The screw rotation within a stator causes displacement of the pumping liquid. A Single screw water pump is also called a progressive cavity water pump. This type of pump is primarily used when smooth and non-pulsating flow is needed. It can efficiently handle abrasive liquids and fluid containing solid particles. A single-screw water pump is also reversible, non-clogging, and has high suction capabilities.

Figure: Showing a single screw water pump

Twin or two-screw water pump

The twin-screw water pump consists of two intermeshing screws in the pump casing and a single suction design. Its operation is based on the principle of positive displacement. Further, it has sufficient clearance between the screws and the casing; hence it can efficiently operate in dry conditions. This type of pump is used to transfer non-homogenous fluid and abrasive and non-abrasive fluids.

Figure: showing a twin screw water pump.

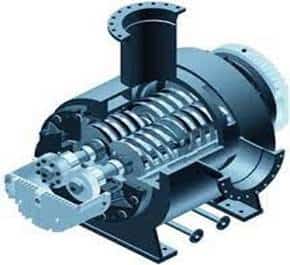

Triple or three-screw water pump

A triple-screw water pump consists of three screws, one driving screw (connected to a motor), and two driven screws (positioned as opposite idler rotor). Unlike two-screw water pumps, a triple-screw water pump does not use timing gears.

Figure: showing a triple screw water pump.

Four-screw water pump

A four-screw water pump has two rotors with two screw thread sections per rotor. The screws face opposite directions, and they have a double suction design. A four-screw water pump sucks water from the suction port, splits it equally, and scatters it to both ends of the pump. The fluid then rushes through the pump and re-unites at the middle of the pump, where it exits through the discharge port. Like the twin-screw water pump counterpart, a four-screw water pump uses timing gears to run the second rotor.

Applications of screw water pumps

- Screw water pumps are used in seawater handling.

- They apply in wastewater treatment (sludge and sewerage handling).

- Uses in irrigation and agricultural processes

- They are used in low-lying dewatering regions

- They are used in handling chemicals.

- They are used in food processing (transferring jelly, yeast, ketchup, sauces, etc.)

- They find uses in offshore and marine applications.

- They are used in power generation.

- They are used as pressure boosters in long distance fluid transportation.

Advantages of a screw water pump

- A screw water pump performs well at a low net suction pressure head (NPSH).

- They are self-priming, can reverse, and have efficiency.

- A screw water pump is gas tolerant and can handle free and entrained gases without suction loss.

- Screw water pumps are incredibly reliable.

- They can handle fluids with different viscosities and high-volume flow.

- Their noise level and discharge pulsations are very low.

- They can pump highly viscous liquids.

- They can handle water containing solid particles, e.g., sludge and sewerage.

- They provide a constant flow rate even if the pressure is varied.

- The two-screw water pump type can run dry for some time without damage

- A two-screw water pump type can operate without any speed reduction gears.

- Screw water pump water at extremely high fluid flow rates.

- Their compact constructions and sizes facilitate easy installation and maintenance.

Disadvantages of a screw water pump

- The initial acquisition and installation cost of a screw water pump is very high.

- It isn’t easy to scale the pumping rate below 50 cubic meters per hour.

- A screw water pump requires the installation of a gas ballast to transfer light gas.

- They provide low pumping speed and lower absolute pressure when used to transfer light gases without gas ballast.

Troubleshooting as screw water pump

The pump gives out low-pressure discharge

- The pump’s NPSH is below the level specified by the screw water pump manufacturer. Increase the suction pressure and fluid level of the suction tank or reduce the pump speed.

- The bypass valve is not operating. Inspect the bypass valve operating pressure and spring conditions and replace/ adjust if necessary.

- Screws are worn-out. Inspect and replace the screws if it is necessary.

Loss of suction

- The suction filter is clogged. Check the inlet filter and clean or replace

- Viscosity is exceptionally high. Ensure fluid viscosity is within the range specified by the screw water pump manufacturer.

The pump produces extreme noise and vibration

- The relief valve is opening and closing rapidly. Increase the relief valve set pressure as directed in the pump manufacturer’s guide.

- Some internal components are worn out. Check the screws, bearings, and casing for wear and replace them if necessary.

- Some pump parts are contacting/ rubbing against each other. Inspect the pump for contacting parts and perform any necessary repairs.

- The pump system is blocked. Inspect the system for blockage, and ensure the valves on both the suction and discharge sides are working perfectly

The pump ingresses too much air

- Pipe work connections are severely worn out. Inspect, repair, or replace the pipe connection.

- The pump speed is low. Increase the pump speed to the level recommended by the screw water pump manufacturer.

- The suction port sealing is defective. Inspect and repair pump sealing.

The pump cannot self-prime

- The motor direction is wrong/reversed. Inspect the motor rotation direction and reverse if it is necessary. Ensure motor rotation matches the direction of the arrow provided on the nameplate by the screw water pump manufacturer.

Summary

A screw water pump is a rotary displacement pump comprising one or several screws that intermesh inside a casing to move water from one location to another. It works on the principle of positive displacement (PD) whereby it repeatedly encloses a fixed of water between sealed cavities and transfers it mechanically through the pump system. Screw water pump manufacturers design the pump in different types, including single-screw, twin-screw, triple- screw and four-screw water pumps.

The screw water pump can cater to several industries, including wastewater, shipping, chemicals, paper, power plants, oil, gas, etc. Typical uses of screw water pumps include pumping irrigation water, handling seawater, and wastewater treatment. They also apply to abrasive and non-abrasive liquids, with and without solid particles. A screw water pump is self-priming, highly reliable, and efficient in operation. They also provide a quiet operation and low pulsation discharge. However, the initial acquisition and installation cost of a screw water pump can be too expensive for a small business.