Vertical Inline Pump

What is a vertical inline pump?

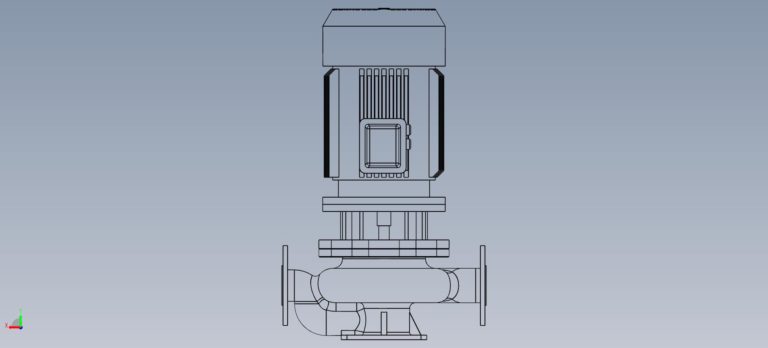

A vertical inline pump is a type of centrifugal pump with the suction and discharge nozzles in line with each other, and it is specifically designed for vertical installation. The inline design of the suction and discharge nozzles is for the pump to provide a smooth flow of liquid through the system. A vertical inline pump consists of a centrifugal pump with inline design, AC electric induction motor, impeller closed in a pump casing, and mechanical seals. The vertical design of the pump makes it ideal for small pump rooms and installations where space is confined as its horizontal alternative requires about 3 times more space. These pumps are suitable for the electric drive only and are available for a wide range of flow rates and pressure heads.

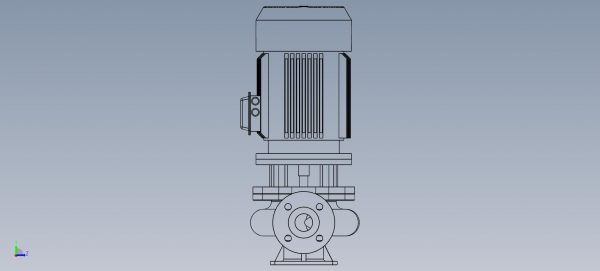

Figure: Vertical inline pump

Vertical inline pumps are extensively used for the transfer of low viscosity fluids such as water and some chemicals. They are also used as circulator pumps in applications where the water flowing through a pipe network needs to be pressurized. In most commercial applications, vertical inline pumps are suspended along with the piping network like valves. Vertical inline pumps are considered better than horizontal inline pumps because they have high efficiency and can tolerate higher temperatures and pressure.

Working principle of a vertical inline pump

A vertical inline pump works based on the principle of the forced vortex. This principle states that when a mass of fluid is rotated through an external force, its pressure head rises, leading to the transfer of the fluid from one location to another. The working of vertical inline pump follows the steps below

- The motor impeller is rotated through a directly coupled AC electric induction motor.

- The rotation of the impeller creates a vacuum inside the pump casing. Due to atmospheric pressure outside the pump, water is forced into the pump casing through the suction nozzle

- The water first strikes the blades of the impeller where it is rotated radially and axially outwards, due to the centrifugal force acting on the blades, until it passes through all of the impeller components.

- The impeller blades impart kinetic energy on the fluid and directs it towards the diffuser chamber at a very high speed.

- In the diffusing chamber, the speed of the water is gradually decreased leading to the conversion of the high-velocity energy into a high-pressure head. The diffuser then guides the water to the pump outlet and into the delivery pipe to be transferred to the required location.

Designs of vertical inline pump

Vertical inline pump has three different types of designs: monoblock or close-coupled design, rigidly coupled design, and spacer coupled design.

Monoblock or close-coupled design

The monoblock or close-coupled design of a vertical inline pump consists of a single shaft connecting the motor to the pump head. As such, the motor bearings stand the fully rotary load of the shaft during operation. Vertical inline pumps with close-coupled designs are highly suitable for light duties and short operation periods at full motor speed. For an inline pump with a close coupled design, however, the repair of internal components can be quite challenging because a standard off shaft motor cannot be used and sourcing must be done from the original manufacturer.

Figure: close-coupled design of vertical inline pump

Rigidly coupled design

As the name implies, this design of vertical inline pump has a separate motor & pump shaft which must be aligned and strongly fixed in place using a coupling. Vertical inline pumps with a rigid coupling design are usually very strong as the shafts are thicker. They are also easier to repair because a standard motor can be easily sourced and replaced if a failure occurs.

Spacer coupling design

The spacer coupling design of the vertical inline pump involves connecting the pump and motor shaft vial flexible coupling. Vertical pumps of this design have two pairs of bearings, one pair within the motor, and two separate shafts. Therefore, the pump’s radial loads are evenly distributed over a large number of components. These pumps are suitable for applications demanding short maintenance periods and a low amount of downtime. Such applications include engine cooling, boiler feed, and fire pumps.

Application of vertical inline pumps

A vertical inline pump has numerous applications across different industries including the flowing

- Irrigation

- Water and service water supply systems

- Air conditioning

- Hot water heating systems

- Hydrant system

- Deluge system

- Monitor systems

- Water transportation

- Cleaning system and industrial recirculation system

Advantages of vertical inline pump

- Vertical in-line pumps offer a space-saving design. In a vertical inline pump, the motor and service clearance is located above the pump casing, hence less floor space is required for pump installation

- Vertical inline pumps are easier to install because they have a simplified piping network

- Suitable for high pressure and temperature

- An inline vertical pump has less noise and vibration. The vertical shaft orientation is naturally balanced and gravitation force does not act against the direction of shaft rotation

- They have high reliability and efficiency

- The close-coupled design does not require shaft alignment. In the close-coupled design, the pump impeller is directly keyed to the motor shaft. This eliminates coupling, additional bearing assembly, and the need for shat alignment.

- Vertical inline pumps also have a higher Net Positive Suction Head (NPSH) compared to suction pumps

Disadvantages of vertical inline pump

- A Vertical inline pump is difficult to maintain. The motor and the impeller of a vertical inline pump must be disassembled from the volute to service the mechanical seals. This becomes a major problem for large motors, above 25 hp

- It requires vertical clearance for installation and maintenance

- The weight of the pump accumulates below the volute which can lead to stress concentration

- Vertical inline pumps experience mechanical seal problems. Mechanical seals may fail or dry out due to infiltration and accumulation of gases in the seal chamber. Leakage in the mechanical seals can damage the motor.

- The pump is prone to corrosion. Vertical inline pumps may corrode due to seal leakage above the pump casing.

- A vertical inline pump easily traps air in its volute compared to the conventional suction pumps. The presence of trapped air can interfere with the proper working of the pump

- Vertical inline pumps are non-self-priming. Priming is the process of filing the pump with fluid to drive out air from the system and to get the system ready for operation. A vertical inline pump cannot pump air or gases because they cause air binding, which may damage the pump impeller.

Vertical Inline pump troubleshooting

This section provides a guide on how to diagnose and solve various common issues about vertical inline pumps.

The vertical inline pump does not give discharge after startup

- The suction lift is too high

- Raise liquid level in the suction tank

- lower the pump to reduce the static lift

- Clear the inlet of any obstruction

- The vertical inline pump operation is reversed

- Check that the direction of the motor rotation matches the direction of the arrow on the pump casing

- Reverse the motor polarities

- Air in the pump or suction pipework

- Fill the pump or pipework with water to drive out the air from the pump system

- Remember pump cannot prime with air on the suction side

- Impeller, strainer or check valve clogged

- Inspect and clean any blockage in the valves

- Insufficient monomeric head

- This is caused by high friction losses that exceed the pump design

- Increase the pump power

- use large-diameter pipes

- Ensure all valves are open

Your vertical inline pump noise level too high

- Air in the liquid

- Submerge the suction pipe to prevent the formation of vortexes on the surface of the liquid

- Pump working in cavitation

- NPSH is too low

- Ensure the suction line valves are fully open

- Lower the pump level to increase the suction head

- Pump working outside the duty range

- Ensure the correct duty range according to the manufacturers manual

Vertical inline pump experiencing excessive vibration

- Pump impeller partially clogged (Inspect and clean the impeller)

- The impeller is severely worn out or defective (Inspect; replace impeller)

- Oblique or unbalanced shaft (Check shaft and replace or balance as required)

- Poor coupling alignment (Inspect; align)

- Unbalanced parts (Inspect and rebalance parts if necessary)

Inlet pump driver overloaded

- Pump speed is too high (Lower the pump speed)

- Poor coupling alignment (Inspect coupling alignment and realign pump and motor)

- Presence of mechanical friction within the pump (Inspect the pump assembly for any obstruction or deflection)

- Packings wound too tight (Check and loosen nuts on packing glands as necessary)

- The density and viscosity of the liquid exceeds the pump design (Ensure the pump is working on the right fluid, increase the motor size)

- Faulty pump motor (Inspect motor for defects such as poor ventilation, location, and repair or replace motor)

Bearing overheating

- Poor coupling alignment (Check and realign)

- The bearing covers are fixed too tightly (Loosen the bearing covers)

- Excessive grease (drain excess grease)

- Insufficient lubrication or lubricating oil contaminated with dirt (Check the level of oil or grease, clean the bearing casing and lubricate)

Summary

This article discusses, in sufficient details, the vertical inline pump, working principle, typical application, advantages and disadvantages, and the common troubleshooting issues about the pump. The vertical inline pump classifies under the centrifugal pumps and has the suction and discharge nozzles lying in straight-line of piping.

A vertical inline pump is specifically designed for vertical installation. The working of a vertical inline pump is based on the principle of the forced vortex where an external force acting on a mass of fluid increases the pressure head of the fluid, leading to the transfer of fluid from one location to another. The vertical arrangement of the pump’s component makes the verticle inline pump highly suitable for small room installations and other applications where space is confined.

Vertical inline pumps are available in different designs such as monoblock or close-coupled design, rigidly coupled design, and spacer coupling design. vertical inline pumps are common in the transfer of low viscosity fluids. They are widely applied for water transportation, cleaning, industrial recirculatory systems, irrigation, hot water heating systems, water and service water supply systems, and many more. Major advantages of vertical inline pumps include high reliability and efficiency, space-saving design, and ease of installation. However, the vertical inline pumps are also limited in that they are difficult to maintain, prone to corrosion, and non-self-priming. The motor and the pump impeller must be pulled out of the casing during servicing, this creates maintenance difficulties and it becomes a major challenge during maintenance of heavier pumps. The vertical inline pumps also require sufficient vertical clearance for installation.

This article also guides on the method of troubleshooting common issues about the vertical inline pump including bearing, overheating, too high noise level, pump vibration, little or no charge after startup. A vertical inline pump is an efficient and reliable means of transporting water that you should consider for your application.