Что такое сцепление?

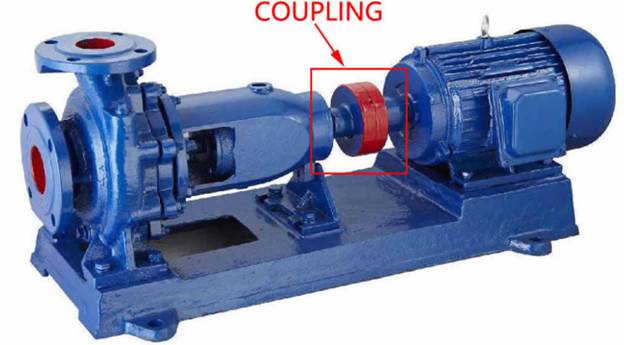

Муфта — это механический элемент, который передает крутящий момент/мощность от одного вала к другому.. В насосах, Муфты соединяют вал первичного двигателя с валом насоса, обеспечивая передачу мощности/крутящего момента, допуская при этом некоторое смещение во избежание выхода вала из строя.. Муфта вращается с той же скоростью, что и вал, к которому она подключена.. Также, coupling in pumps helps absorb vibrations from the prime mover (diesel engine or electric motor) and protects the pump. Centrifugal pump manufacturers design the coupling to not transfer heat from the prime mover side to the pump. Allowing heat into the pump may cause damage to the mechanical seals and thus cause leakage.

Фигура: A centrifugal pump and its coupling.

Причины выхода из строя муфт в насосах

Misalignment

Misalignment occurs due to improper pump and motor installation, pipe strain, and bent shafts. There are three main types of misalignment: angular, parallel misalignment and combined misalignment.

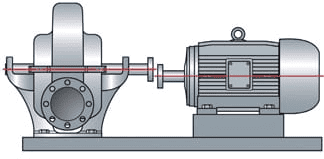

Parallel misalignment is caused by two shafts that have their rotational axes parallel and not perfectly aligned. One of the symptoms of this misalignment is uneven loads on bearings and, таким образом, increased noise and vibrations. В качестве таких, the bearings wears out rapidly. It also causes excess heat on the shafts and seals.

Фигура: Parallel misalignment.

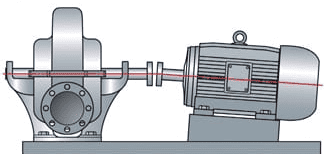

Angular misalignment happens when two shafts/couplings are not connected at the same angle. It causes the shafts/couplings to intersect at a certain angle, as shown below. This misalignment results in high axial loads and excess vibrations, leading to premature wear on seals, и подшипники.

Фигура: Angular misalignment.

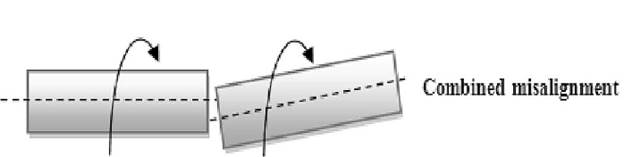

Combined misalignment occurs when the coupling suffers from both angular and parallel misalignment. It is the most common of the three misalignments. It causes several problems in центробежные насосы, such as rapid wear and tear on bearings, and seals. It also leads to low efficiency and severe pump damage. Также, due to misalignment the pump flow rate reduces while consuming a lot of power.

Фигура: Combined misalignment.

Inadequate Lubrication

Some couplings, such as grid and gear couplings, need sufficient Lubrication. Check the lubricant level as recommended by the centrifugal pump manufacturer and flush it out to remove foreign materials that may aid in premature failure.

Poor coupling selection

Delivery and cost are among the main factors when selecting a coupling for your pump. Однако, if it is chosen wrongly, it might have severe consequences, such as damage to the pump and motor, and also cause injury during operation. Other vital factors to consider when selecting pump coupling are misalignment, доступное пространство, backlash, windup, torque, stiffness, inertia, environmental factors, shaft mounting, and ease of maintenance. Также, it is recommended to select a coupling with good dampening capability to reduce vibration and shock.

Poor maintenance

Lack of correct regular maintenance causes premature failure on couplings. Perform preventive maintenance to avoid premature failure. Such maintenance practices include scheduled visual inspections to check for signs of fatigue and wear. Также, performing regular cleaning aids reduces failure. Также, lubricate the couplings according to the centrifugal pump manufacturer’s instructions to prevent wear and overheating.

Torque capacity

There are different types and sizes of pump couplings. Each of the couplings is designed for a specific torque limit. It has been found that 10 к 15% of coupling failures are due to exceeding the torque limit. Excess torque damages the coupling, насос, мотор, and pumping system. Consult pump experts to help you determine the correct coupling for your intended pumping needs.

Environmental causes

Coupling damage could also be due to harmful chemicals and extreme temperatures (cold or hot). Fluids like acids may corrode couplings, thus reducing their mechanical strength. Temperature changes may cause thermal expansion, leading to misalignment and premature failure.

Manufacturing and metallurgical defects

Though rare, coupling could fail due to metallurgical and manufacturing flaws. Such defects could be due to defective materials, poor production methods, and incorrect design considerations.

How to prevent pump coupling failure

- Ensure shafts and couplings are correctly aligned. Dial indicators and laser methods are the two good methods for checking alignment.

- Prevent harmful chemicals and heavy equipment from falling on the pump and coupling.

- Ensure proper installation. Follow the instructions given by the centrifugal pump manufacturer when installing/assembling the pump.

- Perform regular visual inspection to check alignment, смазка, and fatigue on the coupling.

- Avoid excess loads on the pump. Exceeding the coupling/shaft torque limit will cause severe damage even to the pump.

- Clean the couplings and remove foreign materials.

- Store them in a clean, dry place to prevent chemical attack and deterioration.

Symptoms of a failing centrifugal pump coupling

- Excess noise and vibrations.

- Excess shaft vibrations and wobbling.

- Failed mechanical seals leading to fluid leakage.

- Low pump efficiency.

- Чрезмерное энергопотребление.

- Overheating.

- Damaged bearings and seals.

- Cracked coupling.