Насос для перекачки термального масла

What is a thermal oil transfer pump?

A thermal oil transfer pump is a particular type of centrifugal pump with a stainless-steel or cast-steel construction that is mainly used for hot oil circulation and transfer. It primarily applies in closed systems where hot oil is used to directly transfer heat without creating hot spots, which can damage the product through thermal cracking, thermal decomposition, or solidification. Thermal oil pumps help to ensure uniform heating at high-temperature conditions where it is not possible to have direct heat when flammable liquids such as heavy fuel oils are being handled. Thermal oil transfer pump manufacturers usually seal the units hermetically and design the housing to withstand pressure as high as 50 bars and fluid temperatures up to 350 градусов. It is evident in oil burners, furnaces, industrial boilers, or systems. Thermal oil pump provides attractive performance characteristics with a pump capacity of up to 450 кубометров в час, максимальный напор 100 метров, and a pump speed of 2900 об/мин.

Фигура: Showing the configuration of a thermal oil transfer pump

Components of a thermal oil transfer pump

Электродвигатель

The thermal oil transfer pump utilizes an ATEX-approved electric motor to safeguard against explosion under high temperature and pressure conditions. The electric motor provides the mechanical energy to run the pump. It converts electrical energy into mechanical torque output, which is then transmitted to the pump head via the pump shaft and coupling.

Pump housing

The pump housing contains the pump’s internal components, such as the impeller, валы, and bearings housing. It also serves as a pressure containment vessel and carries the suction and discharge ports which help to direct the fluid into and out of the pump ports. Thermal transfer pump manufacturers create the pump body using stainless steel grade 304, литая сталь, или чугун.

Вал

Вал представляет собой вращающийся механический компонент, поддерживаемый подшипниками.. Его основные функции заключаются в том, чтобы нести крыльчатку.. It is usually made from stainless steel and is connected to the prime mover via a flexible or rigid coupling.

Рабочее колесо

Рабочее колесо представляет собой ротор, который служит для увеличения кинетической энергии и давления жидкости.. It is usually mounted on the pump shaft and housed in the pump casing. Он оснащен рядом лопаток с загнутыми назад лопатками..

Подшипники

Основное назначение подшипников — поддерживать ротор и правильно выравнивать его с неподвижными концами под действием радиальных и осевых сил.. The thermal oil transfer pump manufacturers fit the devices with rolling ball bearings to contain the relative motion of the rotor assembly.

Всасывающий и выпускной патрубки

The fluid enters the thermal oil transfer pump through the suction inlet and exits through the discharge outlet.

How does a thermal oil transfer pump work?

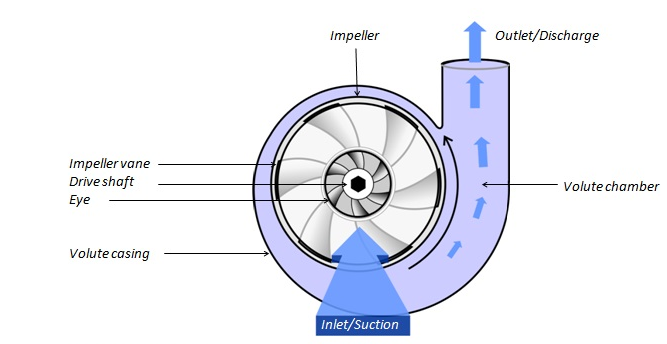

When the motor turns on, the pump shaft rotates the impeller at a very high speed. The centrifugal effect of the rotating pump impeller creates a vacuum inside the pump casing, which allows the high-temperature oil to enter through the pump inlet. When the oil strikes the impeller blades, the centrifugal force moves it radially and axially outwards while imparting great kinetic energy until it enters the diffusing chamber at a very high velocity. В диффузоре, the extreme kinetic energy converts into a high-pressure head, and then the oil is directed into the discharge pipe, where it flows to the designed location.

Фигура: Working of a thermal oil transfer pump

Types of thermal oil transfer pumps

Stainless steel thermal oil transfer pump

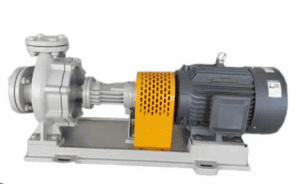

В этом насосе, all the wetted components feature stainless steel grade 304 строительство. The corrosion-resistant material enhances the pump’s durability and performance. This pump can handle oil containing abrasive particles and corrosive, viscous fluids.

Фигура: Showing a stainless-steel thermal oil transfer pump.

End suction thermal oil transfer pump

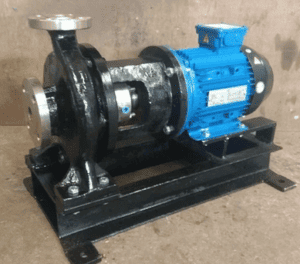

An end suction thermal oil transfer pump draws thermal oil axially into the suction and discharges it at 90 градусов на всасывание. The pumped fluid usually comes in from one side of the pump and discharges from the top. End suction thermal oil pump can be either frame mounted or close-coupled to the pump body. В зависимости от приложения, this type of pump can be driven using an electric motor or diesel engine. It has a low initial cost.

Фигура: Showing an end suction thermal oil transfer pump.

Single suction thermal oil transfer pump

В этом насосе, the thermal oil enters the impeller from one side and exits from the other. The single suction thermal oil transfer pump offers a smooth operation and is easy to repair.

Double suction thermal oil transfer pump

In a double suction thermal transfer pump, перекачиваемая жидкость поступает с обеих сторон рабочего колеса и выходит из средней секции. Поскольку жидкость поступает с обеих сторон рабочего колеса двойного всасывания., осевые усилия с обеих сторон эффективно компенсируются. This pump, следовательно, is less susceptible to wear and tear caused by axial thrust and can last longer. It also reduces cavitation because of the reduced inlet speed.

Фигура: Showing a double-suction thermal oil transfer pump.

Applications of thermal oil transfer pumps

The thermal oil transfer pump is extensively used in many industrial systems, such as hot oil circulation, oil burners, furnaces, and boiler feed. They are also widely used on the offshore platform and for boiler systems on board a ship or vessel.

- Thermal oil transfer pumps are used to transfer hot oils for heating purposes or hot oil to oil burners.

- It is used as a circulation pump in industrial heating systems to handle heat transfer oil up to 350 градусов.

- They are used to pump thermal oils at high temperatures without external cooling.

- They are used to feed oil burners or as an oil circulation pump for circulating heating oil as part of an extensive boiler feed system.

Advantages of a thermal oil transfer pump

- Thermal oil transfer pumps provide optimal performance and require minimal maintenance time.

- They can handle oil and temperatures of up to 350°C.

- They have minimal life cycle cost and excellent reliability.

- They have high energy and operating efficiency.

- They have a simple and compact structure, which is easy to install and maintain.

- They utilize ATEX-approved motors for potentially explosive environments.

- They can manage high flow rates of up to 8300 liters per minute at a pressure of up to 50 bar; таким образом, it is perfect for applications requiring high pressure and large flow.

- They are perfect for low and high-viscosity thermal oils up to 50,000 CP.

- They are available with a double mechanical seal system to allow cooling of the seals.

- They can work with various thermal oil oils, включая, Duratherm, Paratherm, и многое другое.

- Они обеспечивают стабильную и непрерывную производительность..

Disadvantages of a thermal oil transfer pump

- An intense load can fail the thermal oil transfer pump.

- Они подвержены кавитации..

- It has limited suction power due to the use of rotational speed.

- They are prone to leakage due to weary gaskets.

- Qualified personnel must maintain the high pressure and temperature device when needed.

- The heat transfer oils of thermal oil systems are harmful to the environment and thus require the use of safety heat exchangers, special shaft seals and valves, and spill troughs with leakage detection in every joint.

Troubleshooting a thermal oil transfer pump

Насос не запускается

- Перегорел предохранитель или сработал автоматический выключатель.. Inspect the thermal oil transfer pump for a blown-out fuse and replace it if necessary.

- Недостаточное питание панели.. Ensure the motor receives the proper voltage and current according to the thermal oil transfer pump manufacturers’ guide.

Нулевой разряд после запуска

- В насосе или всасывающем трубопроводе есть воздух. Vertical inline centrifugal monoblock pumps cannot prime with air on the suction side. Убедитесь, что насос или трубопроводы заполнены водой, чтобы удалить воздух из насосной системы..

- Встроенная помпа работает в обратном порядке.. Check that the direction of the motor rotation matches the direction of the thermal oil transfer pump manufacturer’s arrow on the pump casing. Поменяйте полярность двигателя.

- The check valve is fitted incorrectly. Install the check valve properly or replace it.

- The pump’s monomeric head is insufficient due to high friction losses exceeding the pump design. Be sure to raise the pump power to the level recommended by the thermal oil transfer pump manufacturers. Open all the valves and ensure the delivery pipes are of the correct sizes.

- Входное отверстие насоса заблокировано. Очистите канал от любых препятствий.

- Засорено рабочее колесо или обратные клапаны.. Устраните засорение рабочего колеса и клапанов..

Насос сильно вибрирует

- Крыльчатка сильно изношена. Inspect and replace the impeller with another one from the thermal oil transfer pump manufacturer if you find it fit.

- Избыточная тяга из-за механической неисправности.. Осмотрите насос в сборе и устраните все недостатки..

- Вал насоса наклонен или несбалансирован. Осмотрите сообщение, перебалансируйте его по мере необходимости, или замените его.

- В насосе имеются несбалансированные компоненты.. Inspect and rebalance the thermal oil transfer pump components as necessary.

- Вал погнут. Разобрать и при необходимости заменить вал..

Насос работает шумно

- The rotating part rubs on the stationary component. Dismantle the pump and correct the rotor assembly.

- Some pump parts are loose. Tighten the components to the torque level recommended by the thermal oil transfer pump manufacturers.

- Некоторые компоненты насоса чрезмерно изношены.. Осмотрите узел ротора на наличие изношенных подшипников или крыльчаток и при необходимости замените их..

- Насос работает в условиях кавитации. Ensure that the net suction pressure head meets the thermal oil transfer pump manufacturer’s specifications. Обязательно полностью откройте клапаны всасывающей линии..

- Насос работает за пределами рабочего диапазона. Ensure the correct duty range according to the thermal oil transfer pump manufacturer’s manual.

Подшипники имеют короткий срок службы

- There is excessive cooling of the water-cooled bearing, resulting in condensation of atmospheric moisture in the bearing housing. Уменьшите поток охлаждающей воды.

- Вал погнут. Осмотрите и при необходимости замените вал..

- Подшипники изношены из-за износа вала.. Замените их при необходимости.

- Вращающиеся детали трутся о неподвижную часть.. Исправьте сборку..

Привод насоса перегружен

- Скорость насоса слишком высока. Уменьшите скорость насоса.

- Внутри насоса имеется механическое трение.. Осмотрите узел насоса на предмет каких-либо препятствий или отклонений..

- Неправильное напряжение питания. Check that the pump receives the proper voltage following the thermal oil transfer pump manufacturer’s guide.

- The density and viscosity of the thermal oil exceed the pump design. Ensure that the thermal oil transfer pump suits the particular application.

Резюме

A thermal oil transfer pump is an edge-cutting centrifugal device featuring a stainless-steel or cast-steel construction that is mainly used for hot oil transfer and circulation. Thermal oil transfer pump manufacturers usually design the units to be hermetically sealed with a pump casing capable of withstanding high pressure and temperature. Thermal oil transfer pump mainly applies in closed systems to directly transfer hot oil without causing hot spots, which can damage the product through thermal cracking, thermal decomposition, or solidification. Thermal oil transfer pumps are evident in many industrial systems, such as hot oil circulation, oil burners, furnaces, and boiler feed. They are also found in the offshore platform and boiler systems on board ships or other marine vessels. Thermal oil transfer pumps provide optimal performance and require minimal maintenance time. These units also have minimal life cycle costs and excellent reliability. The use of ATEX-approved motors enhances the applicability of thermal oil transfer pumps in potentially explosive environments.