Горный пожаробезопасный погружной насос для песка

What is a mining Flameproof submerged sand pump?

The mining flameproof submerged sand pump is a pump designed to deal with the sand discharging challenge for low-flow and high-head pumps. It also provides a solution to the challenge of water discharging in explosive hazardous mines where there may be methane or coal dust contained in the air. The pump is designed and manufactured to the standard of MT/T671-2005 Flameproof Submerged sand Pump for Coal Mines. It is called flameproof because it adopts rigorous flameproof measures for the motor and uses cast steel for the motor casing. Environments containing flammable and hazardous content such as dust and gas can be risky to workers because the pump motor can trigger a large-scale explosion. The flameproof motor design, следовательно, helps to contain flares and sparks as soon as they are produced. By isolating the hazardous content from the working environment, it protects workers and facilities from fires that could halt operations. The pump can also be submerged in water for a long-time service.

Фигура: Mining flameproof submerged sand pump

This pump is used in coal mines to pump the shallow water on the surface of working grounds and roadways. Mining flameproof submerged sand pump manufacturers design the pump with impressive performance parameters such as a wide range of flow rates (от 10 к 500 кубометров в час), a high head (вплоть до 450 метров), and a working pressure of up to 3.0 Mega Pascal. A mining Flameproof submerged sand pump offers several benefits in applications, including compact structure, легкий, easy movability, самовсасывающий, double-faced seal, outstanding durability, security and suitability, и многое другое.

Components of a mining Flameproof submerged sand pump

Электродвигатель

The electric motor is the source of mechanical power in a mining flameproof submerged sand pump. Двигатель запускает насос для перемещения жидкости в необходимое место назначения.. It is connected to the pump shaft using flexible coupling to transmit torque. Двигатель может быть постоянного или переменного тока в зависимости от характера источника тока.. Most mining Flameproof submerged sand pumps use a type of AC motor called a three-phase squirrel cage synchronous motor with a rated power frequency of 50HZ and rated voltage of 380V, 660V, or 1140V. The mining flameproof submerged sand pump manufacturers also design the electric motor to meet the flameproof design requirements established by the National Fire Protection Association (NFPA).

Волюта (Корпус)

Кожух узкий воздушный- проход вокруг рабочего колеса. Корпус действует как защитный сосуд под давлением и имеет всасывающие и нагнетательные порты.. Он содержит жидкость и направляет поток в насос через всасывающую трубу и из насоса через нагнетательную трубу..

Рабочее колесо

The impeller is the component comprising a series of backward-curved vanes and usually mounted on the pump shaft and housed in a watertight casing. Его основная функция — вытеснять жидкость через насос за счет увеличения кинетической энергии и давления жидкости.. Impeller has many designs, в том числе осевой, радиальный, одинарное и двойное всасывание.

Фигура: showing a double suction impeller

Вал

The shaft is a rotary mechanical component riding on bearings as an integral part of the rotor assembly. Его основные функции заключаются в том, чтобы нести крыльчатку.. Обычно он сочетается с первичным двигателем (то есть, электрический двигатель). Mining flameproof submerged sand pump manufacturers use stainless steel and carbon steel to manufacture pump shafts because such materials can overcome vibrations and heavy loads during pump operation.

Подшипники

Основное назначение подшипников — поддерживать вал или рабочее колесо и правильно выравнивать их с закрепленными концами под действием радиальных и осевых сил.. Они также помогают уменьшить трение между вращающимся валом и статором и сдерживают относительное движение узла ротора..

Волюта (Корпус)

Кожух узкий воздушный- проход вокруг рабочего колеса. Корпус действует как защитный сосуд под давлением и имеет всасывающие и нагнетательные порты.. Он содержит жидкость и направляет поток в насос через всасывающую трубу и из насоса через нагнетательную трубу.. The pump casing has two designs: axially or radially split, each with its unique pros and cons. An axially split casing design has a horizontal joint allowing the two halves to separate horizontally or parallel to the shaft axis. Radially split casing design features a vertical joint and two halves to open perpendicular to the shaft axis.

Всасывающая труба

Всасывающая труба состоит из двух концов- один конец подключается к входу насоса, а другой погружается в воду. The lower end of the suction pipe is fitted with a foot valve to prevent the backward flow of the pumping fluid and a strainer to inhibit foreign bodies from entering the pipe.

Доставка трубы

Как всасывающая труба, the delivery pipe also has two ends. One end connects to the outlet of the pump while the other delivers the water at a designed height. Основное назначение всасывающей трубы – подъем жидкости в требуемую зону..

How does a mining Flameproof submerged sand pump work?

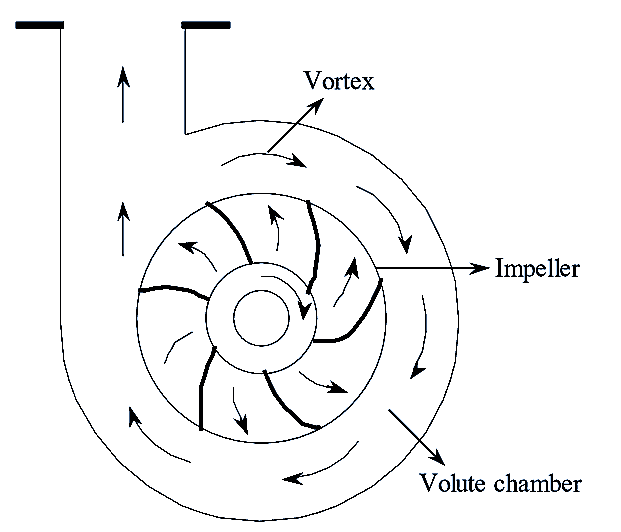

Когда насос запускается, the pump rotor, directly coupled to the electric motor via coupling, rotates at the same RPM as the motor. Due to the pump impeller centrifugal effect, a vacuum is created inside the pump casing allowing water to enter through the suction pipes. Когда вода попадает на лопасти рабочего колеса, центробежная сила перемещает воду радиально и аксиально наружу, пока она не попадет в спиральную камеру с очень высокой скоростью.. В спиральной камере, the extreme velocity is converted into a high-pressure head that allows the water to discharge from the pump to the desired height through the delivery pipes.

Фигура: Working of the pump

Types of a mining flameproof submerged sand pump

Double suction mining flameproof submerged sand pump

В этом насосе, the pumping fluid enters from either side of the impeller and exits from the middle section. The pump is less likely to experience cavitation because of reduced inlet flow.

Фигура: showing a double suction Mining flameproof submersible sand pump.

Single suction mining flameproof submerged sand pump

The flameproof submerged sand pump of a single type, the fluid enters the impeller from one side and exits from the other side. Single suction pumps offer smooth operation and are easy to repair.

Фигура: Showing a single suction mining flameproof submersible sand pump.

Applications of a mining flameproof submerged sand pump

A mining flameproof submerged sand pump mainly finds applications in coal mines, sewerage treatments, and drainage operations. Typical uses include the flowing:

- A mining flameproof submerged sand pump is used to pump shallow water in the working grounds of coal mines.

- It is also suitable for the coal mine roadway and mining working face and other working environments containing explosive air mixture.

- They are used for the drainage of sewage containing solid particles.

- They are used to discharge groundwater and water containing suspended sand, silt, and pulverized coal grains and rock debris.

- mining flameproof submerged sand pump is also used for cleaning up the alluvial sediment drainage water storehouse

- They are used in disaster relief and emergency drainage

- It is also used for petrochemical drainage explosive gas environment because of their flameproof motor design

- It is also used for disaster relief drainage

Advantages of a mining flameproof submerged sand pump

- A mining flameproof submerged sand pump eliminates the risk of explosion in explosive and hazardous locations such as coalmines.

- It has a simple design and easy to control.

- It has a compact design which is easy to install.

- The pump requires minimal repair and maintenance.

- Идеально подходит для больших объемов воды и широкого диапазона скоростей потока..

- The pump is self-priming hence it doesn’t require the user to prime it manually.

- It is highly reliable in drainage operations.

- It is energy efficient.

- It can pump water containing sand, silt, and explosive content without posing hazards to the operator.

- The pump is submersible and can be very quiet in operation.

- It is resistant to corrosion and abrasive wear.

Disadvantages of mining flameproof submerged sand pump

- Mining flameproof submerged sand pump is prone to leaks and operation failures due to weary gaskets.

- They are sometimes installed in locations that are truly deep and difficult to reach. Due to the difficulty in accessibility, the pump is left to operate without regularly checking its condition and status.

- Routine inspection and maintenance of the pump is not easy when submerged in water.

- The impellers are prone to blockage which may lead to pump damage.

- Интенсивная нагрузка может привести к выходу насоса из строя.

Troubleshooting a mining Flameproof submerged sand pump

Двигатель не работает

- The fuse has failed. Осмотрите и при необходимости замените предохранитель..

- Нет питания для управления панелью. Check that the power cables are connected per the mining flameproof submerged sand pump manufacturers’ guide. Проверьте главную панель ввода.

- Кабели насоса оборваны. Осмотрите и при необходимости замените кабели..

Есть рециркуляция всасывания или нагнетания.

- The pump is operating at low flows rates. Check that the pump’s flow rate is as recommended by the mining flameproof submerged sand pump manufacturer.

The pump doesn’t give any discharge

- Impeller seized. Осмотрите крыльчатку на предмет засорения и очистите ее..

- Выпускная труба заблокирована. Осмотрите и очистите выпускную трубу.

- The water level in the sump is insufficient. Check water input to the sump.

- Насос работает в обратном направлении. Ensure that the motor rotation direction follows the mining flameproof submerged sand pump manufacturers’ guide. Поменяйте полярность двигателя.

Low pump capacity

- Pump working in reverse. Обратная полярность накачки

- The impeller of the pump casing is partially clogged. Disassemble and clean the pump interiors.

- The Discharge pipe is blocked. Осмотрите и очистите сливные трубы..

Excessive pump vibration and noise

- One or more pump components are unbalanced. Осмотр и повторная балансировка компонентов насоса.

- Large misalignment between the pump shaft and the engine shaft. Осмотрите и выровняйте валы.

- Pump bearings or impeller is won out. Осмотрите подшипник и рабочее колесо на предмет износа и при необходимости замените их..

- The pump operates in cavitation. Ensure the inlet valves are fully open and the pump is working at the speed recommended by the mining flameproof submerged sand pump manufacturers.

Детектор утечки активирован.

- Detector cable compromised either through wear, повреждать, или контакт с маслами. Inspect the cable and replace it.

Термальный поход

- Уровень остановки слишком низкий. Ensure that the stop switch level is set according to the manufacturer’s guide.

- Напор насоса слишком низкий. Adjust the pump head or install a control valve to detect back pressure inline the mining Flameproof submerged sand pump manufacturers’ set value.

Резюме

The mining Flameproof submerged sand pump is a pump designed to the standard of MT/T671-2005 Flameproof Submerged sand Pump for Coal Mines. It is called Flameproof because it adopts rigorous flameproof measures for the motor and uses cast steel for the motor casing. The flameproof design makes it possible to contain flares and sparks as soon as they are produced and to protect workers and facilities from fire hazards in extreme environments. The pump helps to handle the sand discharging challenge in low-flow and high-head pumps and water discharging in explosive hazardous mines where there may be methane or coal dust contained in the air. Mining flameproof submerged sand pumps are used for drainage operations in coal mines, draining sewage containing solid particles, and disaster recovery. They offer many advantages including the ability to self-prime, Компактный дизайн, operation safety, minimal maintenance requirement, высокая энергоэффективность, и надежность. Однако, they are prone to leaks and operation failures due to weary gaskets and mechanical seals.