Концевой всасывающий насос

What is an end suction pump?

An end suction pump is a common class of centrifugal pump where the suction is axial, and the discharge is 90 градусов на всасывание. It is usually mounted in the horizontal position and driven through mechanical means such as an electric motor or engine. The electric drive motor shaft can be long-couped or close-coupled to the pump head. Most end suction pumps also feature a back pull-out design with a spacer coupling to allow easy pump maintenance and repair without interfering with the motor alignment. The back pull-out configuration eliminates the need for motor alignment and saves installation space. End suction pump manufacturers create more extensive units with a dual volute casing to minimize the forces acting on the impeller, мотор, вал, и подшипники. End suction pumps are available in single-stage and multistage versions and with different construction materials such as cast iron, бронза, and stainless steel. В общем, end suction pumps have relatively simple engineering and low cost.

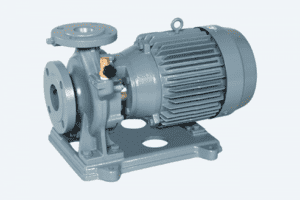

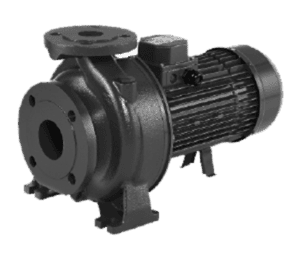

Фигура: Showing the configuration of an end suction pump

Components of an end suction pump

Электродвигатель

Двигатель является источником механической энергии для работы насоса.. It receives an electric power supply and converts it into mechanical torque to rotate the impeller. The type of electric motor can be either a single-phase AC or a three-phase AC induction motor.

Корпус насоса

В корпусе насоса находится рабочее колесо, а также впускной и выпускной патрубки.. Он также содержит спиральную камеру, which helps to convert the kinetic energy into the pressure head. In larger end-suction pumps, the pump casing is usually of the dual volute type to reduce the forces acting on the impeller, мотор, вал, и подшипники.

Рабочее колесо

The impeller is a rotary component designed with a series of vanes or blades that help to displace water through the pump. Когда крыльчатка вращается, the blades impart kinetic energy and velocity to the pumped fluid, enabling it to move through the pumping systems. End suction pumps use a type of impeller known as a closed single-suction impeller. It features support walls on either side of the blades and a single impeller eye to allow the pumped fluid to enter from one side only.

Вал

The end suction pump manufacturers mainly develop the pump shaft from stainless steel material because it has excellent corrosion resistance. The is a rotary solid component located at the center of the pump shaft and supported on bearings, one on each end. It transfers mechanical torque from the motor drive shaft to the impeller during pumping.

Подшипники

The end suction pump employs ball-type bearings located within a bearing housing. The bearings carry the shaft and the impeller, обеспечение правильного выравнивания с закрепленными концами под действием осевых и радиальных усилий.

Связь

A coupling is a device that connects the pump shaft and the motor shaft. It has two main designs, which are close coupling and long coupling. The impeller is directly mounted on the motor shaft in a close coupling. The long coupling features a separate motor and pump shaft and is further divided into the flexible or rigid coupling. Гибкая муфта компенсирует незначительное смещение вала.. The rigid coupling, Однако, cannot tolerate any shaft misalignments, thus requiring precise angular and lateral alignment.

Suction port and discharge port

The suction port is the intake manifold connecting with the inlet nozzle to allow the pumping fluid to enter the casing. The liquid exits the pump through the discharge port, which links with the delivery nozzle or the discharge connections.

How does an end suction pump work?

Когда двигатель запускается, the pump shaft rotates the impeller at the motor RPM. Когда крыльчатка вращается, вытесняет заливочную жидкость внутри корпуса насоса, создание вакуума в глазу крыльчатки. Из-за атмосферного давления снаружи насоса, больше перекачиваемой жидкости нагнетается в насос через всасывающий патрубок и направляется к крыльчатке, чтобы заполнить пустоту. Пока крыльчатка вращается, жидкость будет непрерывно втягиваться в корпус насоса для перекачки. Once the pumped liquid enters the impeller, the centrifugal force acting on the impeller blades pushes it from the center of the impeller to the outer edges and into the volute casing at extremely high tangential velocity. The fluid velocity decreases in the volute chamber due to the gradually expanding flow path, и часть кинетической энергии преобразуется в энергию статического давления. Окончательно, жидкость поступает в нагнетательный патрубок перпендикулярно линии всасывания и под очень высоким давлением, allowing it to flow to the required destination.

Types of end suction pumps

Single-stage end suction pump

The single-stage end suction pump is the most common variant of the end suction pump. It consists of one impeller in the pump casing to increase the flow velocity and pressure to move through the pump. It presents the most uncomplicated design of the end suction pump with many associated benefits such as portability, бюджетный, and ease of installation and maintenance. It is used in most water supply systems and industrial applications to boost water pressure.

Фигура: Showing the configuration of a single-stage end suction pump.

Multistage end suction pump

A multistage end suction pump comprises several impellers mounted in series along the same pump shaft and housed in different chambers to help pressurize the pumped liquid in stages. The pumped liquid enters the first stage impeller at the suction pressure and discharges from the last impeller at elevated pressure. The multistage end suction pump can manage higher fluid pressure and flow rates than its single-stage counterpart.

Фигура: Showing the configuration of a multistage end suction pump.

Close-coupled end suction pump

In a close-coupled end suction pump, the impeller is attached to the end of the motor shaft, and the pump casing bolts directly to the face of the motor. It is also known as a monobloc end suction pump. The end suction pump manufacturers mainly employ the close-coupled design for single-stage pumps. It is preferred for many industrial and domestic water supply systems because the close coupling eliminates the need for pump alignment in the field, saving installation and maintenance time.

Фигура: Showing the configuration of a close-coupled end suction pump.

Long-coupled end suction pump

A long-coupled end suction pump has separate motor and pump shafts that join together via a long coupling. The long coupling design allows for faster disassembly and maintenance without interfering with the motor alignment. It also provides an adequate space between the pump and motor to prevent fluid ingress into the motor in case of seal failure. Unlike the close-coupled design, the long-coupled design applies to single-stage and multistage versions of the end suction pump.

Фигура: Showing the configuration of a long-coupled end suction pump.

Applications of end suction pump

The end suction pump manufacturers develop the devices to perform excellently in residential and industrial water supply systems, agricultural /irrigation applications, and HVAC systems for heating, вентиляция, and air-conditioning. Они используются для следующих.

- End suction pumps supply clean water for residential, муниципальный, and commercial uses.

- They are used to supply water irrigation water to sprinklers in agricultural farms.

- They are used for condensate handling and refrigeration and cooling tower installations.

- They circulate hot, cold, or cooing water in air conditioning systems.

- They are used for handling clean or dirty liquid with low viscosity and similar properties to water.

- They are used to support firefighting equipment.

- They are used as pressure-boosting pumps in plumbing systems for large buildings such as big-box stores, stadiums, office buildings, and shopping malls.

Advantages of end suction pump

- End suction pumps have a compact design that is easy to install and operate.

- They have high flow rate capabilities.

- They have few moving parts and occupy very little space.

- The end suction pump provides a steady and consistent output.

- They can withstand high system pressure and temperature.

- They are perfect for a wide variety of clean and dirty liquids with low viscosity and similar properties to water.

- They have high hydrodynamic efficiency and energy efficiency.

- Они обеспечивают широкий диапазон скоростей потока для удовлетворения различных требований применения..

- They have a solid mounting base that eliminates vibration effects and enhances the pump’s reliability.

Disadvantages of end suction pump

- End suction pumps are not self-priming and must always be manually filled with the necessary liquid volume to start the pumping operation.

- Они подвержены кавитации., which may corrode the impeller and the casing.

- They are subject to seal failure, which can cause damage to the motor.

Troubleshooting an end suction pump

Мотор перегревается и глохнет

- Несоответствие напряжения двигателя и напряжения сети. Проверьте напряжение питания двигателя согласно характеристикам, указанным на заводской табличке, и отрегулируйте его соответствующим образом..

- Рабочее колесо сталкивается с корпусом насоса.. Демонтировать насос, align the impeller, или замените его.

- Использование проволоки неподходящего размера.. Убедитесь, что используемые провода соответствуют национальным электротехническим нормам и стандартам для устройств защиты цепей..

Насос дает нулевой расход после запуска

- Насос работает в обратном направлении. Поменяйте полярность двигателя.. Check that the motor rotation direction matches the direction shown in the end suction pump manufacturer’s manual or the movement indicated using an arrow on the pump casing.

- Высота всасывания слишком высокая. Опустите насос или поднимите уровень жидкости в баке.

- Манометрическая головка недостаточна. Ensure all valves are open and the pipe diameter of the pipes meets the sizes set by the end suction pump manufacturers.

- Рабочее колесо или обратный клапан забиты. Осмотрите рабочее колесо и обратные клапаны., и устранить любую блокировку.

Производительность насоса нестабильна

- Насос поднимает жидкость с воздухом. Проверьте глубину всасывающего трубопровода или клапана в жидкости и при необходимости увеличьте.

- Насос поднимает жидкость с воздухом. Проверьте глубину всасывающего трубопровода или клапана в жидкости и при необходимости увеличьте.

- Нижний клапан течет. Осмотрите нижний клапан на наличие утечек и исправьте его..

- Напряжение слишком низкое, приводит к снижению скорости насоса. Проверьте напряжение питания и при необходимости отрегулируйте его..

The pump vibrates excessively, или это шумно

- крыльчатка сильно изношена. Inspect and replace the impeller with another from the end suction pump manufacturers. Убедитесь, что все клапаны открыты и диаметры труб правильные..

- В насосе имеются несбалансированные компоненты.. Inspect and rebalance the end suction pump components as necessary.

- Некоторые детали затянуты слабо. Tighten the pump components to the torque level recommended by the end suction pump manufacturers.

- Вал насоса наклонен или несбалансирован. Осмотрите сообщение, перебалансируйте его по мере необходимости, или замените его.

- Некоторые компоненты насоса чрезмерно изношены.. Осмотрите узел ротора на наличие изношенных подшипников или крыльчаток и при необходимости замените их..

Краткое содержание

An end suction pump is a centrifugal pump with axial suction and the discharge at 90 градусов на всасывание. It is usually designed for horizontal installations and operates using an electric motor or engine. The electric drive motor shaft can be long-couped or close-coupled to the pump head. The end suction pump manufacturers also develop the devices with a back pull-out design to facilitate easy pump maintenance and repair without disturbing the motor alignment. The larger units of end suction pumps contain a dual volute casing, which helps to reduce the forces acting on the rotor. End suction pumps are available in different designs and construction materials to suit various applications. They are used to supply clean water in residential and commercial buildings, agricultural or irrigation farmlands, and to boost water pressure in industrial applications. Significant benefits of end suction pumps include high flow capabilities, эффективность, and compact engineering that is easy to install, operate and maintain.