Масляный насос

ЗАПРОСИТЬ ЦЕНУ ДЛЯ БОЛЕЕ ПОДРОБНОЙ ИНФОРМАЦИИ

What is an oil pump?

Это насос без уплотнений, в котором используются магниты для привода крыльчатки насоса для создания энергии давления, необходимой для транспортировки жидкости.. В этом насосе два магнита.. Два магнита расположены напротив друг друга, создавая рисунок магнитного поля.. Эта схема заставляет приводной магнит вращать ведомый магнит, когда вращается вал двигателя.. Этот тип насоса очень хорошо подходит для транспортировки опасных и агрессивных жидкостей, утечка которых может привести к судебному иску или вызвать высокий уровень ущерба, например, пожар.. В качестве таких, производители магнитных насосов обязаны следовать строгим правилам при проектировании этого насоса, чтобы гарантировать отсутствие утечек при транспортировке опасных жидкостей.. Насос работает, вращая свое рабочее колесо, чтобы создать разницу давлений внутри насоса и поддона.. Эта разница давлений нагнетает жидкость в насос.. Затем насос перекачивает жидкость, используя энергию давления, в заданное место..

How does an oil pump work?

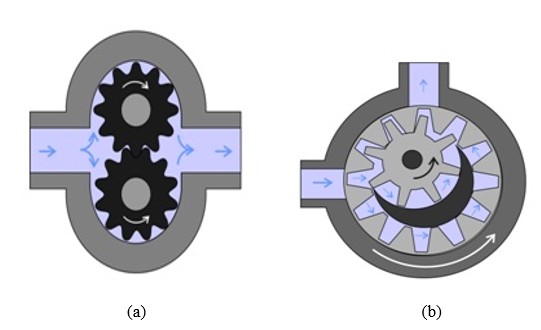

The working of an oil pump depends on the particular category of positive displacement pumps to which the device belongs. Positives displacement pumps have two major types: rotary and reciprocating pumps. Rotary positive displacement pumps utilize the actions of rotating gears, доли, or vanes to move fluids instead of the forward and backward movement of reciprocating pumps. По мере вращения вращающегося элемента, it develops a liquid seal within the pump casing and creates suction at the pump inlet. как следствие, fluid is drawn into the pump, enclosed within the teeth of its rotating gears or lobes, and transferred from the inlet to the discharge side, around the inner side of the pump casing. As the gears or lobes interlock on the discharge side of the pump, they reduce the volume and force the fluid out under pressure. The gear oil pump is the simplest example of a rotary positive displacement pump.

С другой стороны, reciprocating positive displacement pumps work by the repeated back-and-forth movement of a piston, plunger, or diaphragm (also called a flexible membrane). The cyclic motion of such components compresses and forces fluid through the pumping system. Because of their repeated and predictable pumping action, reciprocating oil pumps are perfect for applications requiring accurate metering and dosing, such as fertilizer and chemical industries.

Types of the oil pump

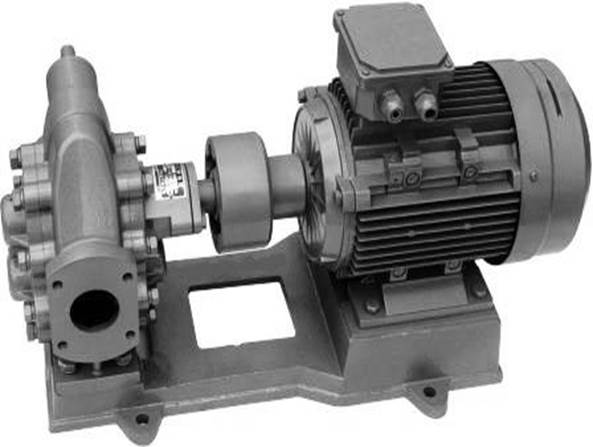

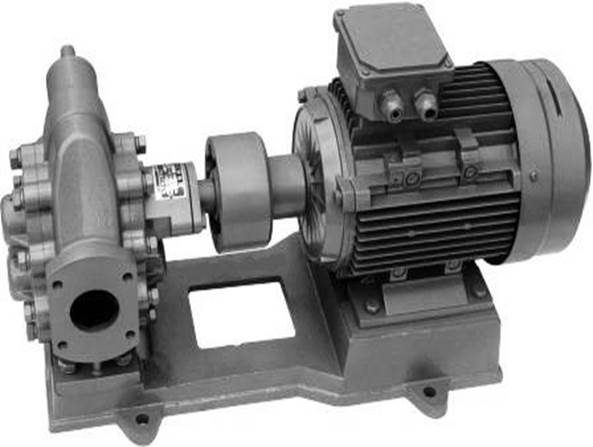

Electric gear oil pump

Электрический шестеренчатый масляный насос является объемным. (ПД) роторный насос, в котором в качестве первичного двигателя используется электродвигатель. It consists of a set of interlocking gears which act as the rotating element to displace fluid through the pump. The electric gear oil repeatedly encloses a fixed volume of oil between the gear teeth and moves it mechanically using a cyclic pumping action. Он особенно подходит для перекачивания масел и других жидкостей с высокой вязкостью и используется в гидравлических системах, а также в коммерческом и домашнем осветительном оборудовании.. Oil pump manufacturers avail the electric gear oil pumps in either external or internal gear configurations. The electric external gear oil pump has two interlocking spur or herringbone gears, while the external gear oil pump has one internal gear and a spur gear rotating inside it in the same direction. These pumps have unique advantages over each other. Например, the external gear oil pump can sustain higher pressure and flow rates than the internal gear counterpart. С другой стороны, внутренний масляный шестеренчатый насос обеспечивает лучшую всасывающую способность.

Pneumatic oil pump

A pneumatic oil pump uses compressed air to create a mechanical effect that helps control and move oil through pipelines. It generates an amplified mechanical force by pressuring air or inert gases, which translates into a high-power source. The Pneumatic oil pump is ideal for transferring low-viscosity fluids, including motor oil, old waste oil, антифриз, transmission oil, ATF oil, and other liquids with similar properties. Manufacturers configure the pneumatic oil pump for either wall-mounting or placing directly on the drum or tank.

Фигура: Showing the configuration of a pneumatic oil pump.

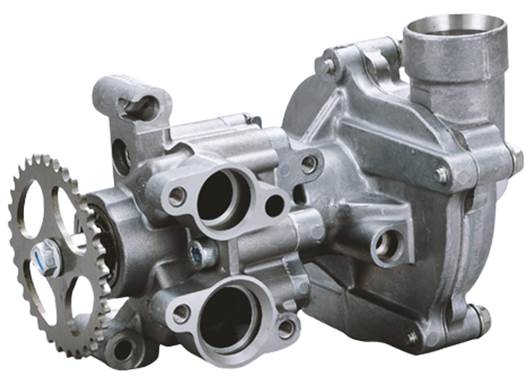

Self-priming oil pump

A self-priming oil pump also uses gear or lobes to circulate oil under pressure to transfer oil, but it is constructed to hold the necessary volume of oil inside the cavity or pump body to start the pumping process. The self-priming oil pump has many variations, such as a twin gear self-priming pump, rotor self-priming pump, and front cover self-priming pump. Because of the self-priming ability, self-priming oil pumps can better handle air pockets, обеспечивая превосходную эффективность работы. Self-priming oil pumps are widely used in the automotive industry as engine oil pumps to lubricate engine components. They also suit frequent and intermittent pumping operations in oil refineries since they eliminate the manual priming stages.

Фигура: Показ конфигурации самовсасывающего масляного насоса.

Thermal oil transfer pump

A thermal oil transfer pump is a particular type of centrifugal pump used for hot oil circulation and transfer. It mainly features a stainless-steel or cast-steel construction. A thermal oil transfer pump primarily applies in closed systems where hot oil is used to directly transfer heat without creating hot spots, which can damage the product through thermal cracking, thermal decomposition, or solidification. It suits many industrial systems, such as hot oil circulation, oil burners, furnaces, and boiler systems on board ships and vessels.

Фигура: Showing the configuration of a thermal oil transfer pump.

Applications of oil pumps

Oil pumps suit various uses in many industries, such as automotive, химический, нефтехимический, мыло, бумага, нефте- и газоперерабатывающие заводы, и т. д.. They perfectly cater to hydraulic power systems in vehicles, подъемное оборудование, и передвижное производственное оборудование. The following are typical uses of oil pumps.

- Oil pumps are used in internal combustion engines to supply lubricating oil, which prevents wear, and tear of engine components and help with cooling.

- They lubricate the automatic or continuously variable transmission, особенно при запуске или остановке автомобиля.

- Они используются для перекачки сырой нефти и дизельного топлива в нефтехимической промышленности..

- They pump high-viscosity fluids such as oil, краски, и смолы.

- Они используются для перекачивания масел., растительный жир, и сливочное масло в пищевой промышленности.

- They are used for accurate blending, metering, and dosing operations in chemical and agricultural applications.

- They are also perfect for transferring low-viscosity fluids, including motor oil, old waste oil, антифриз, transmission oil, ATF oil, and other liquids with similar properties.

- Thermal oil transfer pumps are used to transfer hot oils to oil burners and to pump thermal oils at high temperatures without external cooling.

Advantages of the oil pump

- They are perfect for transferring high-viscosity oils up to 50,000 CP.

- Они имеют превосходный контроль над выходом.. Hence can be used as a metering or dosing pump.

- They have high reliability and durability. The elements of the oil pump are highly durable and robust.

- They have fewer repairs, less downtime, and a low life cycle cost.

- Они просты в эксплуатации, maintain, and reconstruct.

- Обеспечивают работу без кавитации.

- Oil pumps are lightweight, компактный, и прост благодаря нескольким движущимся частям.

- They can overcome high-temperature conditions.

- Они имеют высокую эффективность и низкое энергопотребление..

Disadvantages of the oil pump

- The oil pump cannot pump fluid with suspended solid particles.

- Oil pumps require precise manufacturing, which might be expensive.

- Oil pumps with gears or lobes pump against back pressure, Любая закупорка ниже по потоку может привести к выходу из строя трубопровода или оборудования..

- The interlocking gears, доли, or exiting air from pneumatic components can be loud.

Selecting oil pump

The selection f an oil pump is based on careful analysis of the following factors

Oil viscosity

The oil viscosity dictates the size and speed of the oil pump. Thin oils require a high-speed pump, while highly viscous oils require a low-speed-high torque pumps.

The elevation of the oil reservoir

If the oil pump has to deliver oil to a higher elevation tank through a one-inch diameter pipe that climbs several feet, then the pump should be capable of handling the weight of the oil column.

Required flow rates

It would help if you determined the liters per minute needed for a particular application. The oil pump should be able to meet that flow rate for smooth operation.

Желаемое давление жидкости

The oil pump should generate the desired output pressure for effective operation. Однако, it should not exceed the maximum pressure for the application because it can wear the plumbing system.

Troubleshooting oil pump

Двигатель не запускается

- Кабель питания сломан. Проконсультируйтесь с лицензированным электриком для проверки и замены оборванных проводов..

- The power supply to the Control Panel is inadequate. Check the power supply and ensure the power cable connections follows the oil pump manufacturer’s guidelines.

- Предохранитель перегорел, или автоматический выключатель сработал. Осмотрите насос на наличие перегоревшего предохранителя и при необходимости замените его.. При необходимости обязательно перезапустите автоматический выключатель..

Насос дает нулевой расход.

- Во всасывающей линии имеется воздушная пробка.. Заполните всасывающую линию жидкостью и наклоните трубопровод вверх.. Убедитесь, что трубопроводы ровные и не имеют перегибов..

- The suction tube is cracked. Inspect and repair or replace the suction tube with another one from the pneumatic oil pump manufacturer.

- The pump is not primed and thus cannot pick up any product. Perform the priming cycle to purge out ant trapped air from the system and allow the pump to generate line pressure and stall.

- Редукционный клапан вышел из строя. Осмотрите и очистите или замените предохранительный клапан..

- The suction line is blocked. Check and remove the blockage.

Насос не может самовсасываться

- Направление двигателя неправильное/перевернутое. Проверьте направление вращения двигателя и при необходимости поменяйте полярность.. Ensure motor rotation matches the direction of the arrow provided on the nameplate by the oil pump manufacturer.

- Подъем слишком высок для скорости насоса.. Прежде чем выбирать насос, убедитесь, что вы понимаете требования к высоте всасывания..

- Насос связан с воздухом. Откройте клапан в линии выпуска воздуха..

Насос работает шумно

- Насос кавитирует. Use pipes of the correct diameter following the oil pump manufacturer. Уменьшите высоту всасывания и очистите фильтры.. Также, попробуйте уменьшить обороты насоса и поднять уровень жидкости в бачке.

- Вибрации в предохранительных клапанах. Отрегулируйте настройку давления до уровня, рекомендованного производителем шестеренного масляного насоса, или при необходимости замените предохранительный клапан..

The pump cycles slow

- The fluid viscosity is too high. Match the pump with the application requirement. Increase pump size, and increase pipe diameter.

- The delivery hose is blocked. Inspect and clean the delivery hose.

Резюме

An oil pump is a mechanical device for circulating oil under pressure to the moving parts of an internal combustion engine. The oil pump constitutes the heart of the engine’s lubricating systems, which supplies engine oil to bearings, pistons, and camshaft, preventing wear and tear of the components and assisting in cooling down the engine. It is a positive displacement pump because oil pump manufacturers develop the unit to repeatedly enclose a fixed volume of fluid and move it mechanically through the pump. An oil pump can also be a rotary positive displacement pump (which utilizes gears, lobe, or vanes to move fluids) or a reciprocating positive displacement pump (which relies on repeated back-and-forth piston movement, plunger, or diaphragm). Кроме того, oil pumps can be electrically or pneumatically powered, depending on the pump type and application. Oil pumps suit various uses in many industries, such as automotive, химический, нефтехимический, мыло, масло, and crude oil and gas refineries. They provide the outstanding benefits of high efficiency, low power consumption, fewer repairs, and less downtime.